Matt –

It's simple to fit a new motor to the original mounting, by interposing an adaptor:

I have just traipsed down the garden to remind myself what I did for my BCA.

I bought it from one of our regular second-hand machinery dealers, who said it came from a university who had also made the somewhat functional-looking inverter dangling from the original motor, with a plug that might have been for a 16A or 32A mains – certainly not regular 13A household type.

The dealer had nowhere in his warehouse to plug it in, so I had to buy it on sight. (I think I had been advised that would be so.) The machine itself was in good condition, despite a couple of small drill dimples in the table.

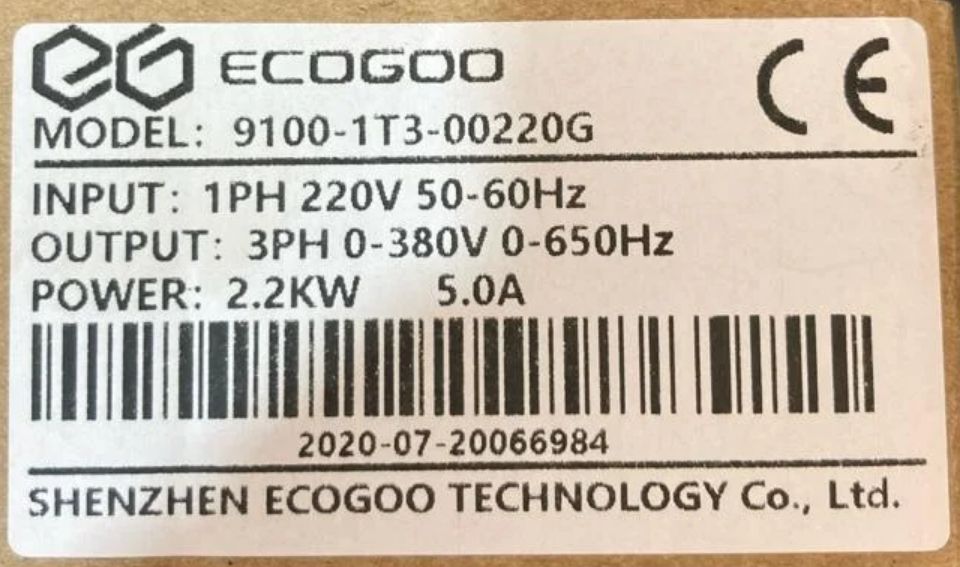

I was not prepared to risk the electrics, so contacted Newton-Tesla.

They were understandably worried about me sticking one of their nice new inverters and controllers on a motor of known type but unknown history, and equally understandably, keen to sell a nice new motor too.

I had no problems fitting the replacement motor, entailing 2 items : –

– An adaptor-plate. I used 20mm thick PVC in near-BCA Grey. You could use aluminium, or as Michael G, says above, plywood! Four clearance holes match the original mounting, and 4 tapped M8 match the smaller new motor's feet. (Use screws with their heads in counter-bores if in plywood, of course.) I turned a broad but shallow central recess from each side to stiffen the plate – possibly needlessly, but PVC is fairly flexible.

– A bush to fit the original pulley on the smaller, new spindle. The important point of course was concentricity. Plus a new key, or the original modified, to pass through the bush wall and fit its new home.

So all quite straightforwards, helped by the machine's open layout.

The tapped / counter-bored holes are necessary to set the plate flush against the pad on the column, which with the plate's thickness help put the pulley in about the right place.

Matt Mackeson.

to mount in its place. ( I have very limited knowledge of such things)

to mount in its place. ( I have very limited knowledge of such things)