In the lockdown I have implemented some of the mods collected over the years. I bought this lathe secondhand more than 25 years ago, and although it has a poor reputation, it has served me well as a bench top lathe. I can now afford something 'better', but it's capacity and familiarity have always won through. The controls lack a quality feel, but accuracy has been fine; yesterday I clocked run-out on the three jaw (using a ground bar) at 0.0003 tir, which is pretty good I think.

Some years ago I fitted a VFD, which solves the problem of a minimum speed which is too high, as well as giving a smoother, quieter drive.

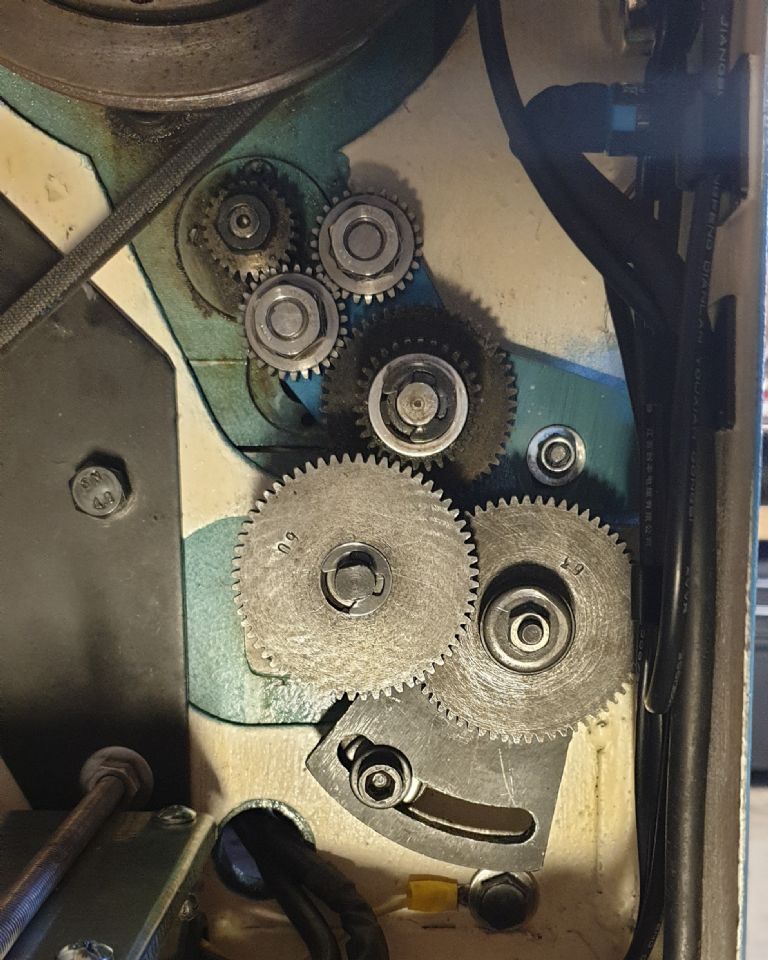

First is an extended banjo to permit l.h. screw thread cutting. There is room for an extra gear to reverse rotation of the lead screw. I needed this to make a new screw for extending the travel of the tailstock barrel by 25mm. Next was a cycle computer to give me rpm. The display shows kph which, with a wheel circumference of 1667mm, is an analogue of rpm.

Next was a cycle computer to give me rpm. The display shows kph which, with a wheel circumference of 1667mm, is an analogue of rpm.

Last is a reversed tailstock. This is possible because the bed is flat and the barrel is on a through bore. It substantially improves reach over the saddle, but requires the barrel clamp to be moved to the other end, which requires a block to be bolted in place, and boring of a 25mm through hole.

Stuart Cox 3.