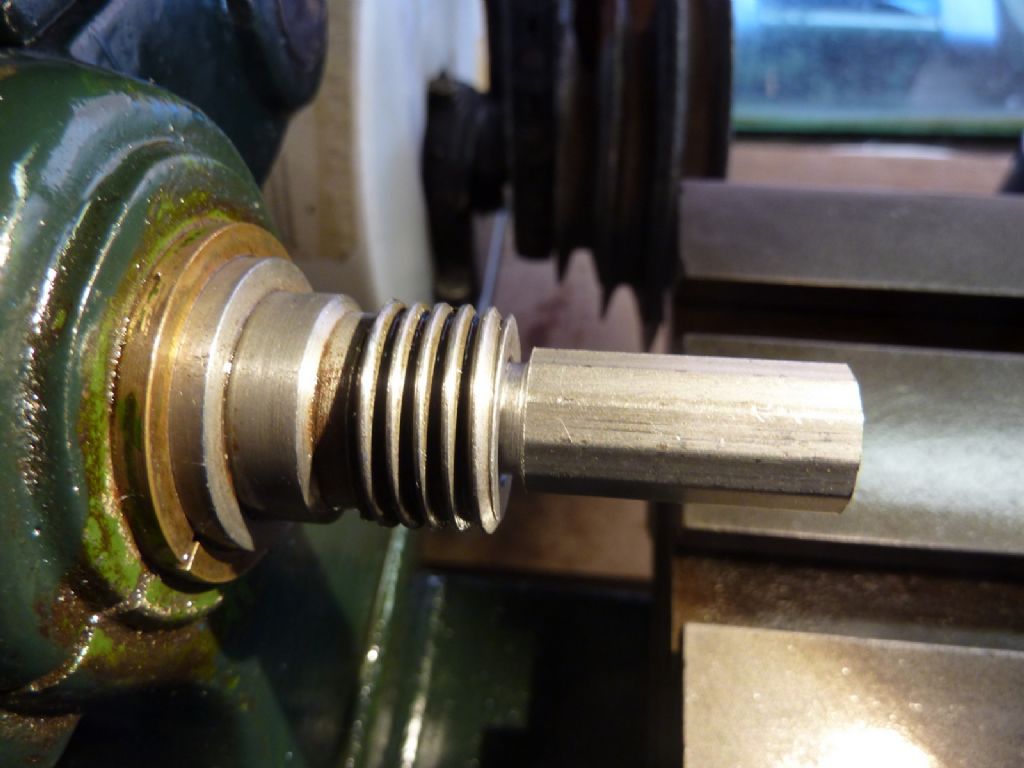

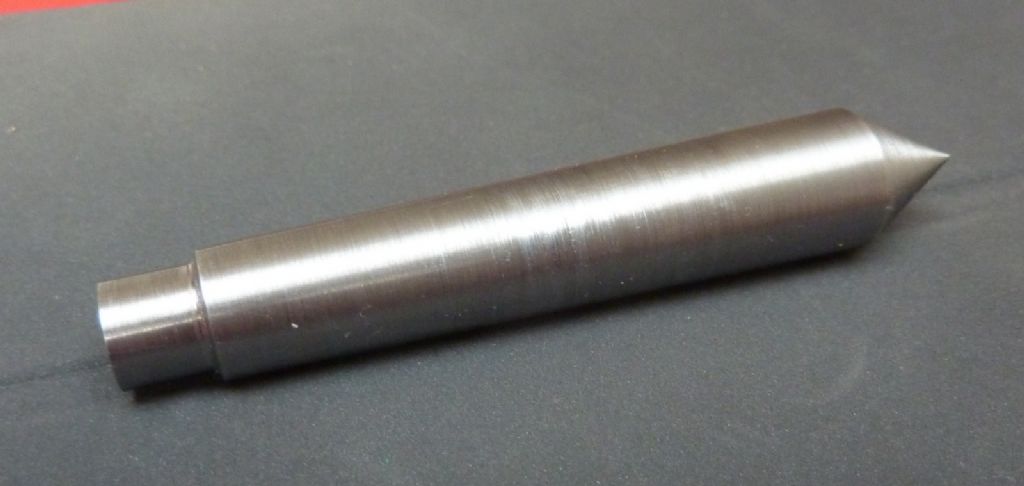

Yesterday evening I turned up a new soft centre to the measurements I'd taken from the headstock taper.

After some trial and error I think I hit the calculated taper angle to within the accuracy that I can achieve but that might still not be the right answer…

The pointy end was turned down with the centre in the headstock once the taper had been done. Once I was past half way through this process I found that the centre was regularly breaking loose and it became rather a frustrating exercise for a while.

As the job progressed I spotted a problem – the cutting tool was slightly above centre (in my defence, bear in mind that up to this point I only had MT1 centres that did not fit the spindle properly and had visible runout at the tip). I corrected this and was able to complete the pointy end without any more breaking loose. I also pop marked it so that I can put it back in the spindle in the same position next time.

So how well does it fit? Initially it seemed to grip very well but the breaking loose did not inspire confidence. All of that mucking about has, however burnished the turning marks to show me where it is gripping and where it is not. The result surprised me a little.

The taper is roughly 2 inches long. At the thick end there is perhaps 1/4 inch which is inside the spindle taper but has not burnished. Then about an inch that is burnished. The remaining part of the thin end has much less burnishing.

This result puzzled me – I was expecting it to grip at either the thick end or the thin end depending on whether my angle was to steep or too shallow… but in fact it is gripping in the middle and at neither end. My theory to explain this is as follows…

The actual machined taper in the headstock is shallower than the taper on the centre but repeated use of MT1 tooling by a previous owner has worn the first 1/4 inch or so into a steeper taper. The upshot of this is that my measurement inside the taper was also wrong because the 'fat end' measurement was measuring inside the worn part.

At the moment I'm thinking that having an inch of the fattest usable part of the taper engaged is not so terrible for a dead centre so I'm not intending to have a second attempt. This should at least allow me to accurately set tools to centre height and do a much better check on the tailstock alignment than I've been able to manage so far.

The tailstock definitely aims low – that is clear from the behaviour when centre drilling but my previous attempts to check the alignment with two centres was inconclusive.

Given my conclusions about the state of the headstock taper I will abandon any thoughts of making a drill chuck arbor to fit. It will either be a collet chuck on the spindle thread or else re-machining the taper to MT1. I have no plans to attempt to machine the taper though until I have had a lot more practice at machining tapers accurately.

Brian Morehen.