Jesper – good evening. Firstly my apologies for not picking up your questions sooner, I've been out of touch for a day.

So, if I may I would like to summarise what we think we know, and answer your question about obtaining the requisite gear.

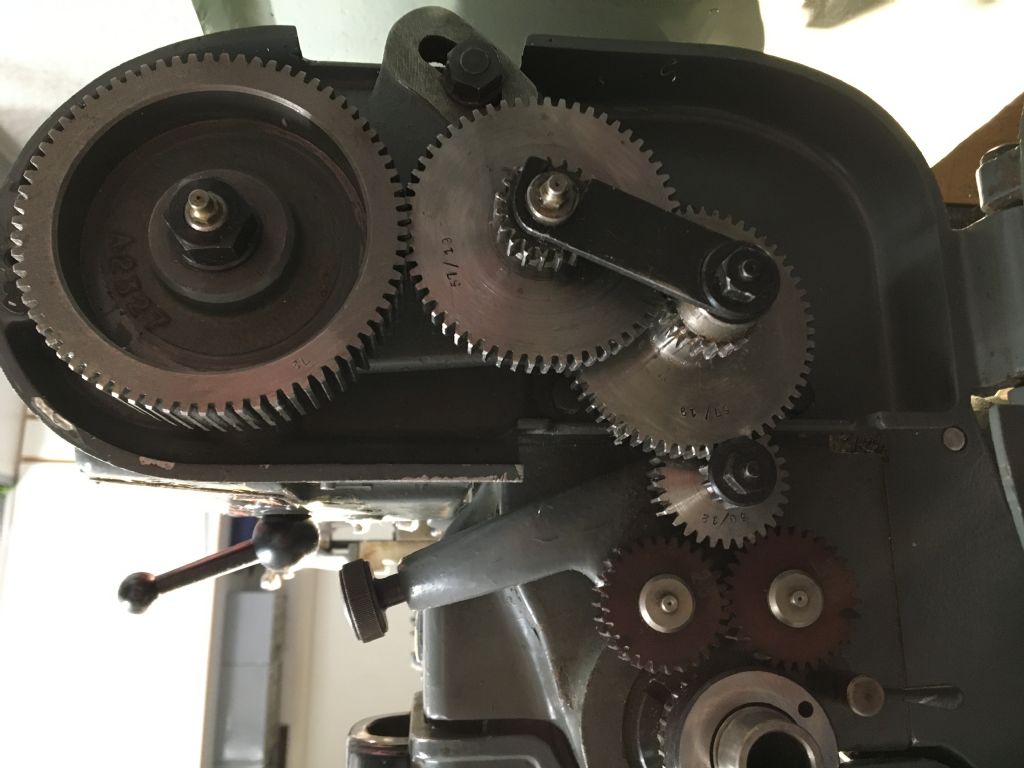

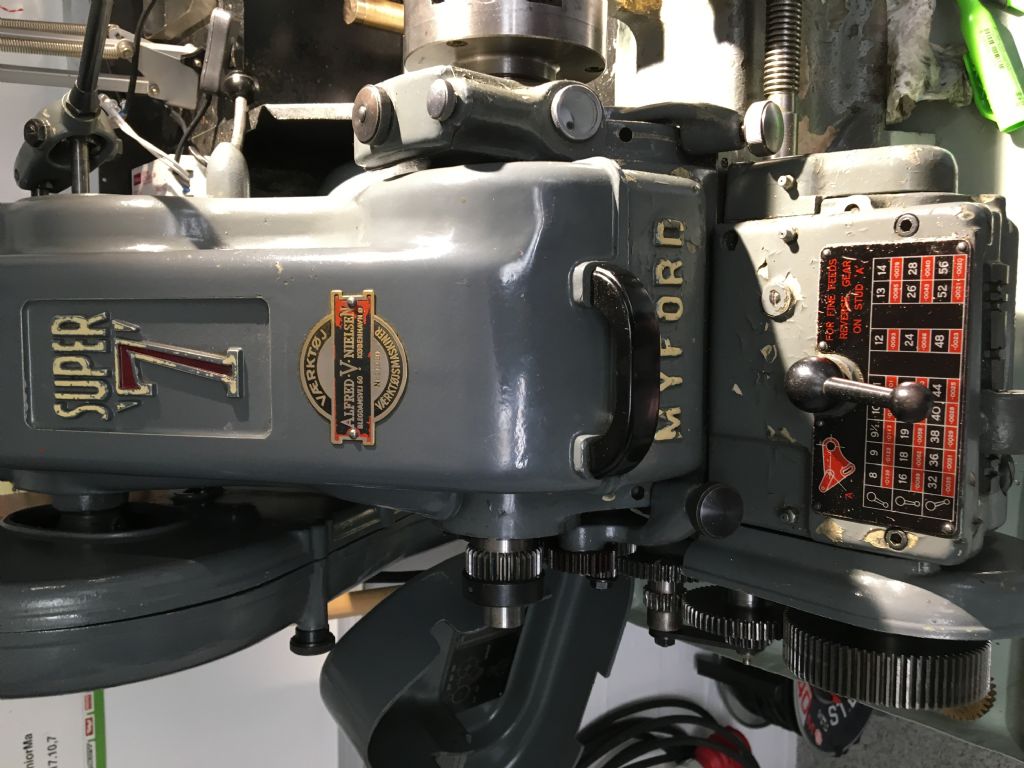

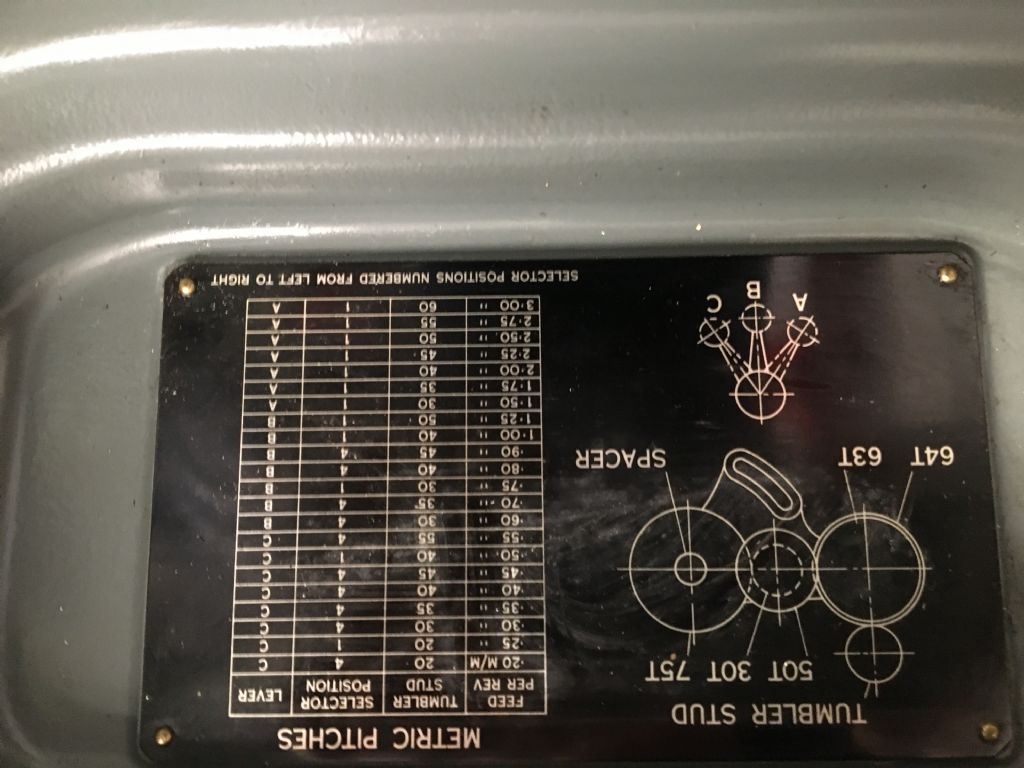

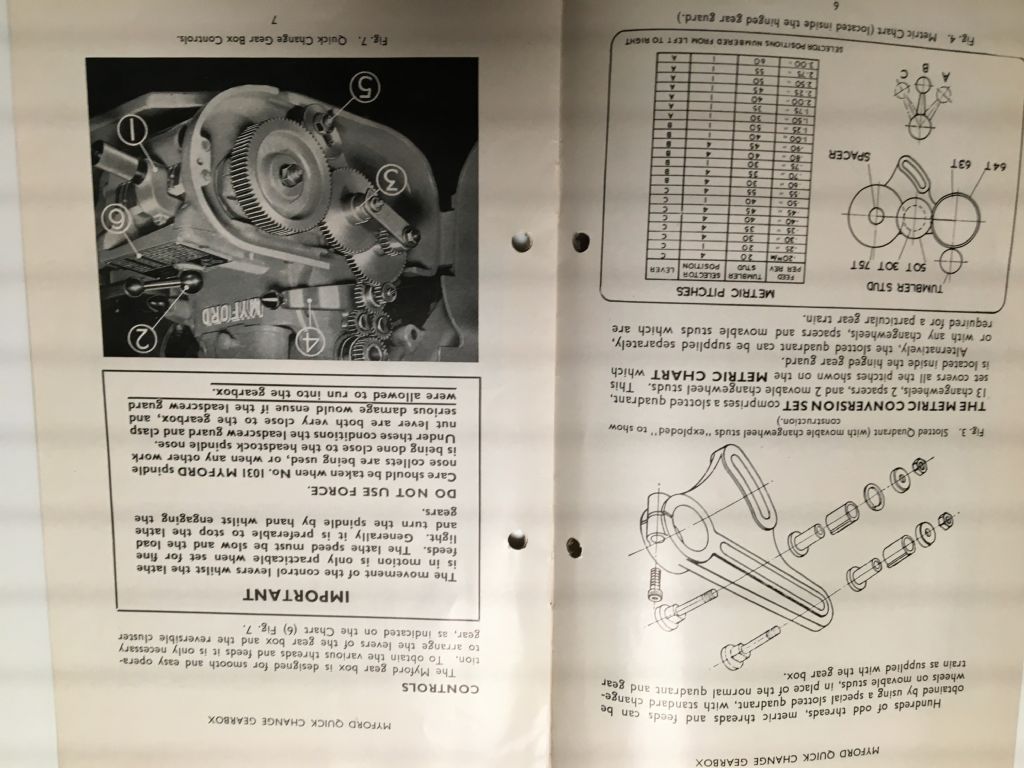

I believe we have established that you have the older type QCGB, that's what the photo's of the lathe indicate, and the fact that you have a 30/12 cluster gear in the gear train on the mandrel gear suggests the same. What we don't know for absolutely certain is whether the lathe cuts the threads as indicated on the gearbox label. It's just possible that there is a mismatch here, and the gearbox cuts either twice or half the threads per inch that is indicated. This of course is when you are cutting an imperial thread such as 20TPI. The label inside the gear cover sows a seed of doubt in my mind, and I would just like to be sure we know where we are starting from before telling you what to do next. Can you try cutting a thread with the gearbox set up for (say) 20TPI – it needs only be a scratch pass to prove the gear train – and confirm that it is 20 TPI that you get.

I chose 20 TPI because it is the same thing as 1.27 mm pitch – and if the M62 nut you were trying to make is only fairly short you may find that using a 20 TPI thread instead of 1.25 mm pitch gives acceptable results. After all the error is only 0,02 mm per revolution – so if your nut is 10 mm thick the thread error is still only +/- 0.08 mm.

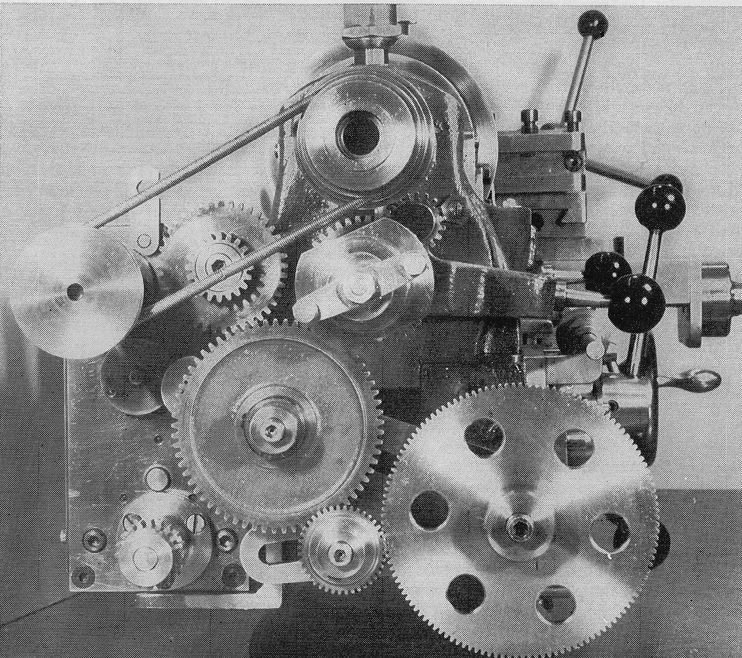

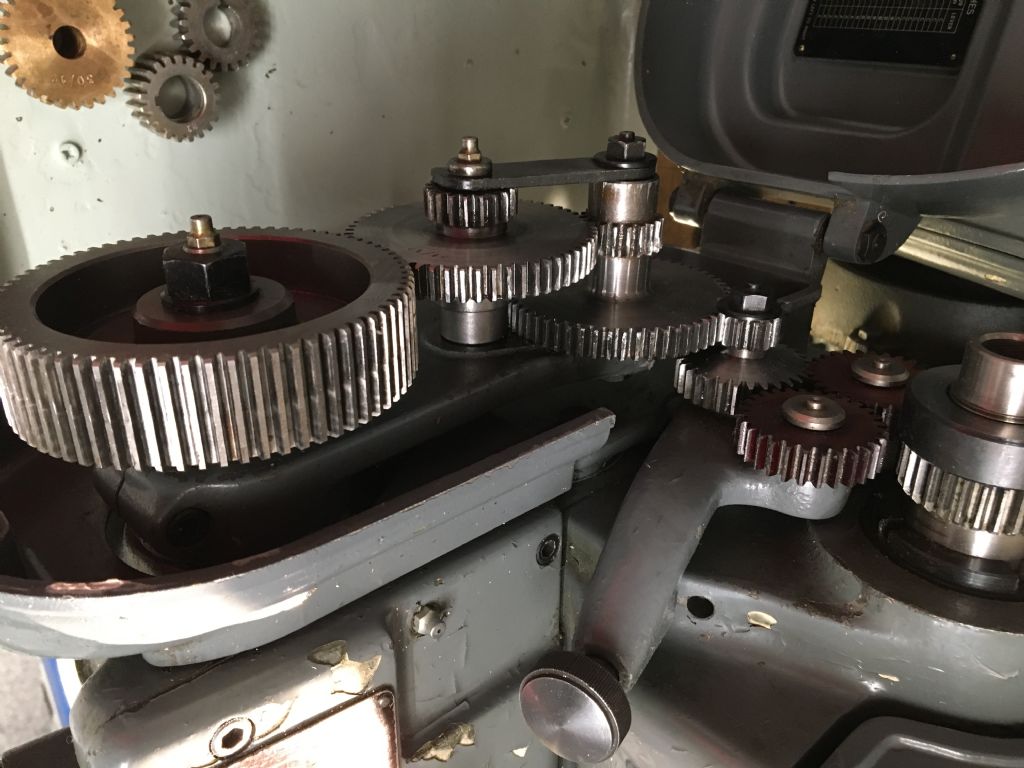

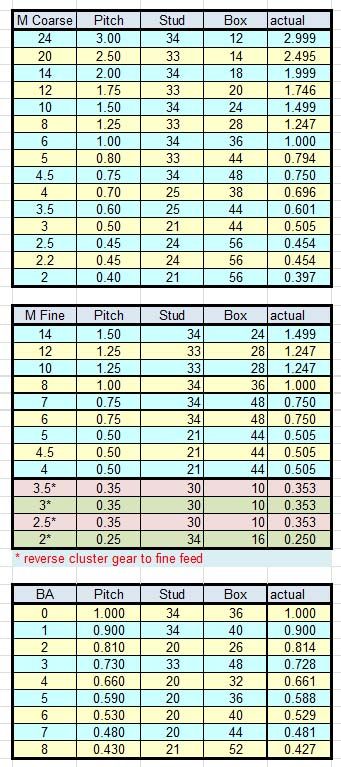

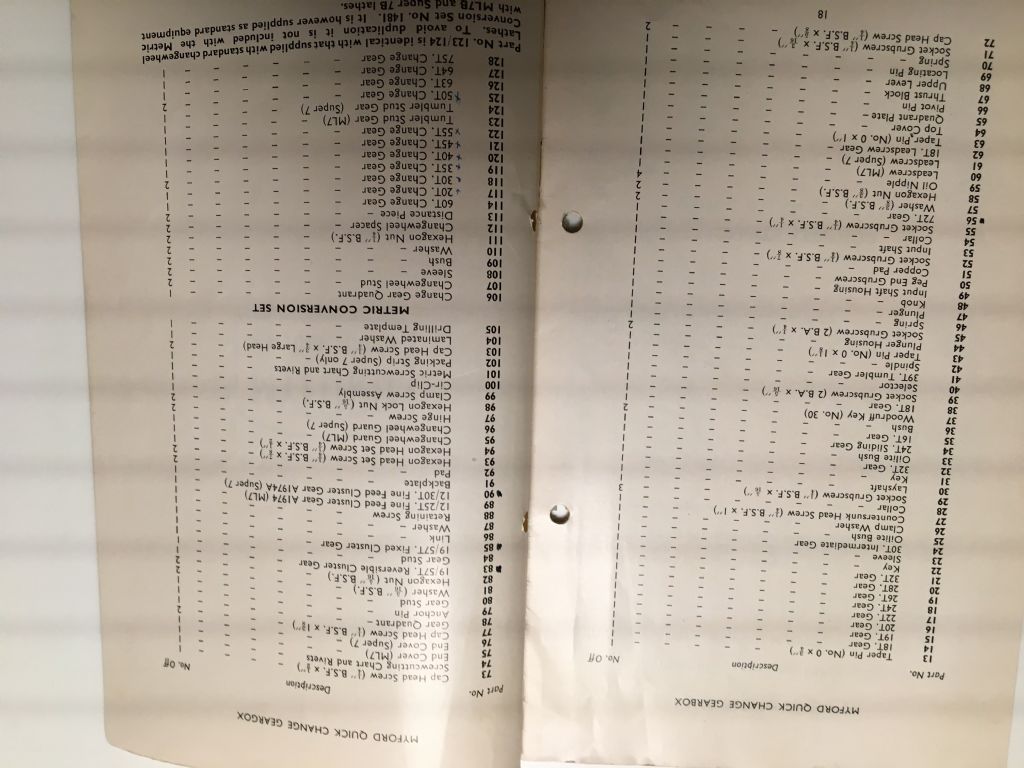

However, we can do better. ASSUMING the gearbox IS the old one, the gear train you have identified starts with a 30 tooth gear with a 12 tooth gear married to it to make a compound gear. This gives the thread per inch selection as per the label on top of the gearbox.

If we change the 12 tooth gear for say 18 teeth we'll get a different set of TPI values for each position of the gearbox selector levers. In this example the gearbox output is speeded up by 50%, so our 20 TPI setting will now cut 13.3 (Edit – I got this wrong in my initial post – it's less TPI because the lead screw is running faster. OOPS!) TPI. Using other input gears gives us control over the threads on the workpiece over and above the "normal" (standard settings.

One such choice is a 17 tooth gear. If we change the 12 tooth gear to be 17 teeth, and set the gearbox levers in the positions for 24TPI we get 16.94TPI, which equates to 1.499 mm pitch. The arithmetic is simple pro-rata gear ratios, but work it out in TPI and then convert to mm pitch last.

So that's a nice accurate answer for 1.5 mm pitch. also 3mm, and 0.75 which is an oddity but it shows the principle. How do we go about getting 1.25 mm pitch.

Do the same arithmetic, and you find you need a 16-1/2 tooth gear. Now whatever I've said before, I haven't worked out a way of making a single non whole number gear. But it isn't a single gear we're working with , it's a compound pair. The other gear of the compound pair was always 30 teeth, giving a 1 : 1 ratio with the chuck, but it doesn't have to be.

16-1/2 : 30 is very close to 16 : 29, so if we change the input gear to be 29 teeth meshing with the tumbler gear, and now 16 teeth driving the otherwise standard gear train going down to the gearbox input we get jolly close to 1.25 pitch. And 2.5, also 0.625, another size we're likely never going to want!

Enough for a moment, this post is long enough already, I'll continue in a second instalment.

Edited By Simon Williams 3 on 25/11/2019 19:37:41

JasonB.

JasonB.

EXERTS EXCESSIVE PRESSURE ON THE LEADSCREW AND GEAR MECHANISMS. GREAT CARE SHOULD BE TAKEN SO AS TO MINIMISE THE LOADS IMPOSED."

EXERTS EXCESSIVE PRESSURE ON THE LEADSCREW AND GEAR MECHANISMS. GREAT CARE SHOULD BE TAKEN SO AS TO MINIMISE THE LOADS IMPOSED."