A week to the day after buying it, I managed to make some swarf on my Faircut lathe.

The lathe is not yet properly installed – I'm figuring out how to construct a sensible drive arrangement with the bits that came with the lathe.

My first attempt more or less reproduced the arrangement that the previous owner had. Unfortunately he never really used the lathe after inheriting it so it turns out that his drive arrangement has a serious flaw – the back end of the cross slide can collide with the motor and/or the drive pulley… apart from the obvious matter of the pulley being in the firing line for swarf.

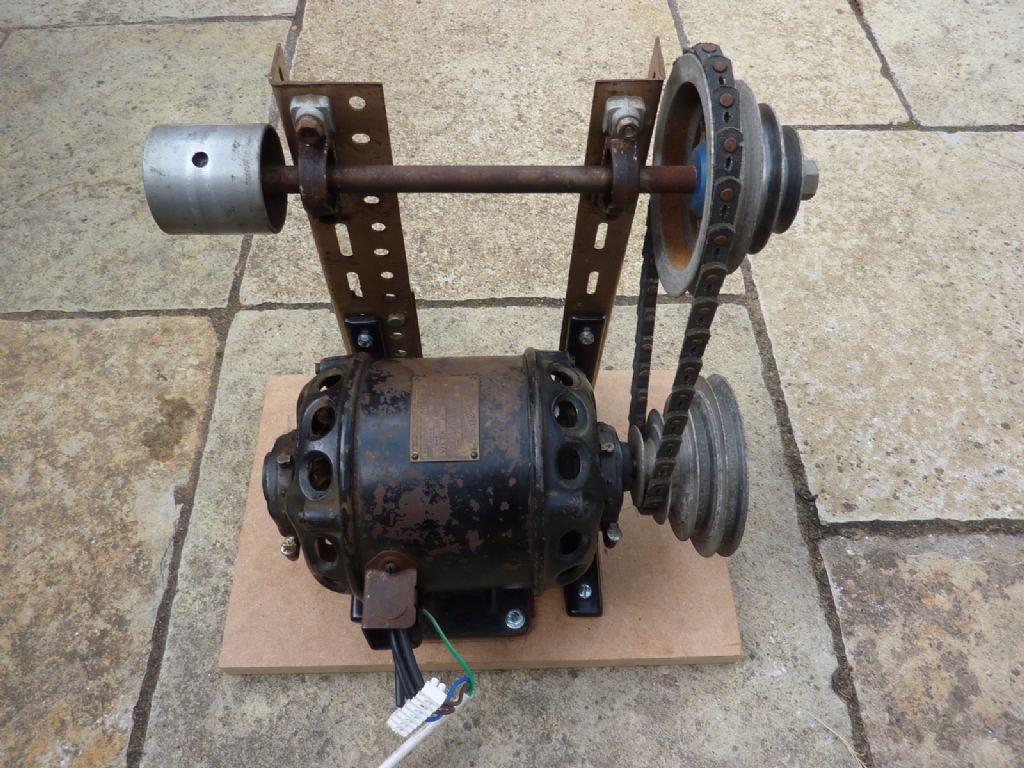

I'm putting the drive system together on a 'sledge' to give me a way to tension the flat belt. The Mk 1 arrangement is below.

I eventually want to get to an arrangement with 3 stepped flat pulleys to match the lathe but for now the objective is to get the thing up and running.

I'm thinking that my next move is to get a pulley mounted in the middle of that shaft but that turns out to require some thought. I've now dismantled the Picador pulley shaft and discovered that it has stepped ends (and also a left hand thread which took me a while to twig). I also discovered that the shaft is aluminium so quite why it looks like rusty steel is a bit of a mystery really. Figuring out how to get the (ball) bearings off would be useful.

The snagging list for the lathe proper is getting longer each time I look at it but the priorities just now are getting the drive system sorted and a sensible electrical arrangement put in place.

Brian Morehen.