I think Steve that other contributors have overlooked the fact that you are purchasing for stock and not for a specific project. You do therefore have to ask what proportion of the tasks you will undertake will involve welding. If, say, only 20%, then it would be foolish not to benefit from the free cutting results that En1A (230M07) will give just to be able to weld the 20%. In this case, either purchase a small stock of weldable steel or purchase as required. Of course, if a large proportion of you activity involves welding then forgoing the free cutting aspect of En1A may be OK.

Another factor is that welding most frequently, though you may be doing something out of the ordinary, involves rectangular materials. In this case, En1A (as per Macreadys) is only available in a small range of imperial sizes and you will have to purchase En3B. I only know of one supplier to the home workshop who lists EnIA in rectangles and having purchased from them what I received was certainly not En1A.

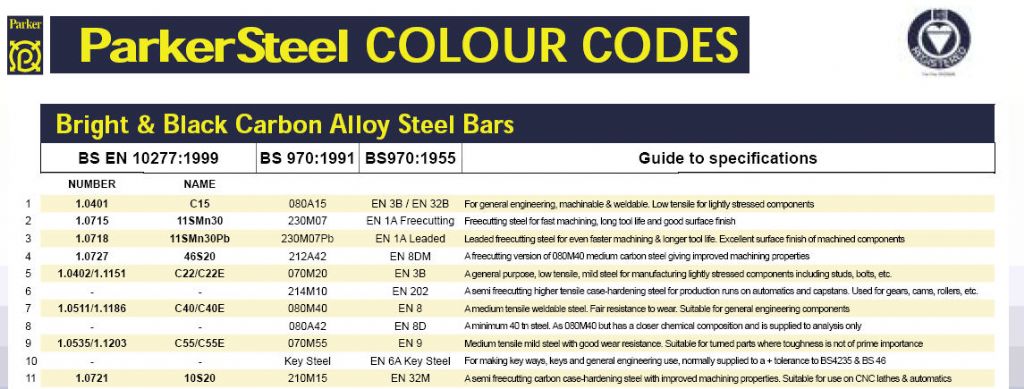

As a guide to relative machinability, Macreadys use 100 for En1A as a baseline for all others, giving 55 for En3B (070M20) and 080A15 (no En number, known as good commercial quality) both of which they quote as being suitable for welding.

Incidentally, they give a value of 130 for leaded En1A

In a nutshell then, do consider how much of your work involves welding before limiting a large proportion of your turning to materials that machine less well.

Harold

Martin Lockett.