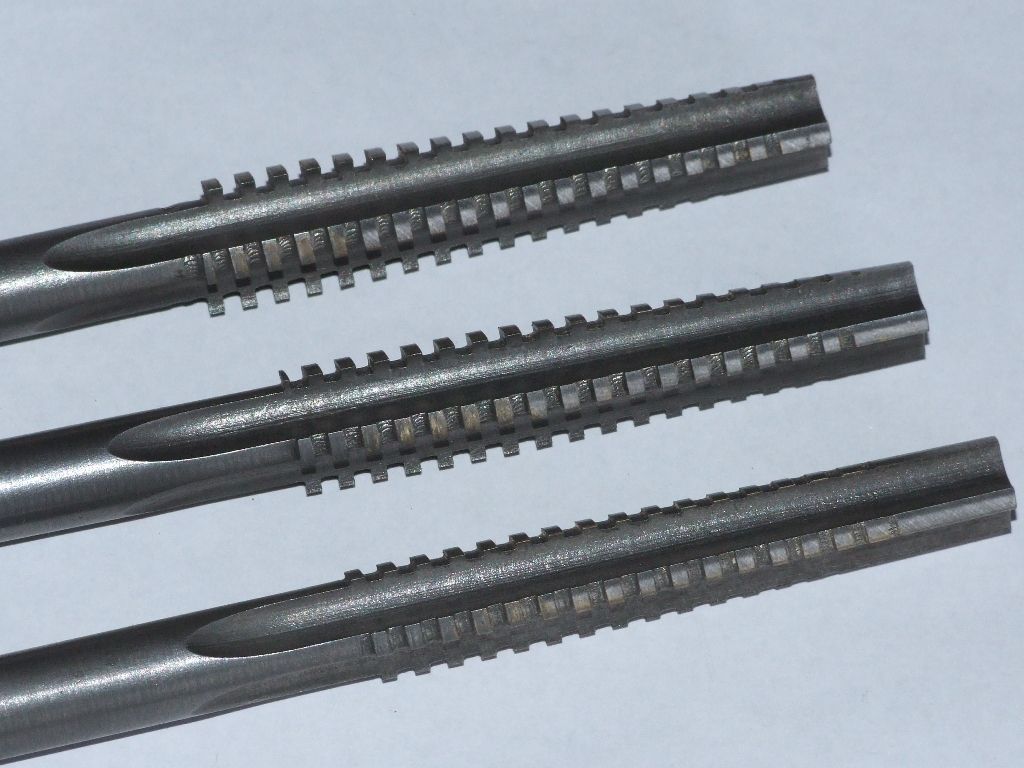

Some years ago I bought a pair of Dormer M12 x 1 serial taps. At that time, it was difficult to find a stockist, and they cost around £35 per tap. They were for a specific job I repeat regularly, so I had to bit the bullet on the price. The tailstock drill chuck grips them more securely than smaller non-serial taps, simply because the turning forces involved are smaller, despite the larger thread diameter.

More recently, I bought some sets of serial taps in more common metric sizes, at much more reasonable cost. However; they are TiN coated and distinctly less sharp than the original Dormer uncoated HSS taps. That was a surprise, and largely negated any advantage in the small thread sizes (M6 and M8).

Surprisingly, Dormer serial taps are even more difficult to obtain nowadays, although I also suspect the price may be even more difficult to justify. Sorry – Dormer Pramet, as it now is.

Like JasonB, I favour spiral flute taps, and it is a joy to use them in a tapping head on the drill press.

I have always used Trefolex paste when tapping, but I recently bought a bottle of Dormer tapping fluid. 'Twas a waste of money; its not as effective as Trefolex, so I will be happy to switch back in a few years, once the fluid is finished.

Marcus

Anonymous.