Okay,

Had another crack at it today and i think i've solved the problem, there are a number of factors that may or may not have come into play with the error.

-Giving the machine a good clean. Was a minor amount of grease and stains that needed de-greasing, and scrubbing but gave it all a wipe down afterwards and put a thin rub of WD40 afterwards to help ward of the rust monsters.

-Those washers really were flimsy! one had bent right out of shape under repeated duress i assume. So i got some washers that were about twice as thick and replaced both of them.

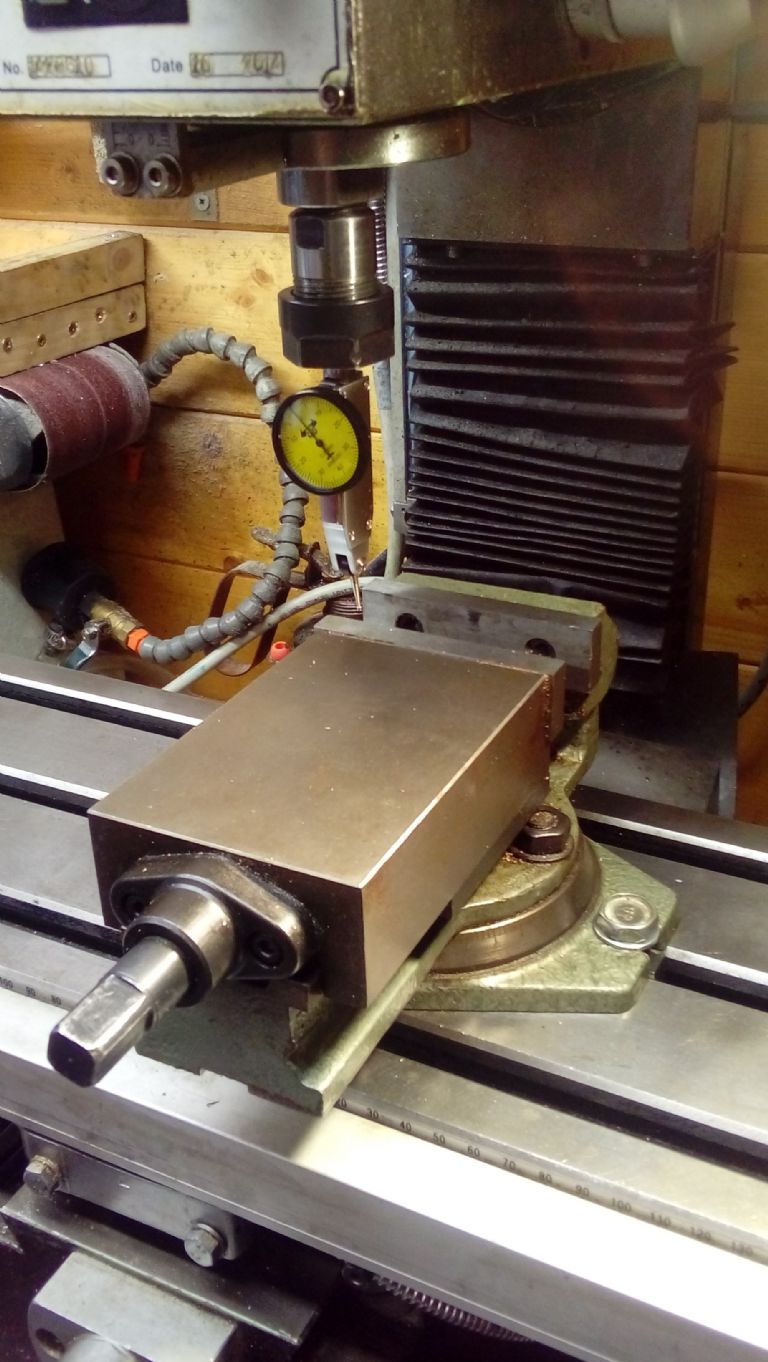

– I have a bad habit of taking the parallel reading off a big vertex gauge block, clamped up inside the vise, which isn't really proper, but this time i did the right thing and took it from the inside of the fixed jaw.

-The vise is pretty durable, i like this model that much, that i have a second one also. But it comes with a swivel base, which is really not useful 99% of the time. But hey.

I had another habit of clamping the base and adjusting the vise on the radial slot, which in hindsight probably may have contributed to the encouragement to twist away. So i left that clamped up and adjusted the vise along the table clamp tabs this time. One pinched up gently and the other a bit looser.

– My number one culprit that i suspect may be the worst of them all. I noticed as i was doing up the bolts that my spanner would catch the draft angle of the casting. Sounds so stupid looking back but definitely very easy to overlook.

I think you can just about see the radial draft near the base of the index markings. Urgh.

But after all this i was able to repeat my adjustment to 0.02 maximum along the length of the vise and NOT let it go walkabout during tightening.

I'm happy with this as i'm only making an aluminium clamp for a laser sight attachment to an air rifle.

Like many times in this, you start out on one thing only to start sorting out something else first.

Thanks for all the pointers,

Michael W

Neil Lickfold.