Posted by Roger Williams 2 on 27/08/2018 08:50:15:

Ive always thought it a bit daft how most people condemn the 4 way tool post and fit quick change ones, when the 4 way is the more solid platform. Not so convenient though.

Exactly, which is why I've stuck with my 4 way toolpost, even though I've got a genuine Dickson toolpost sitting on the shelf. It's odd that many people are happy wasting time taking lots of tiddly weeny cuts, but are obsessed with saving a few seconds with a QCTP.

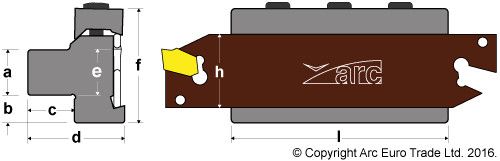

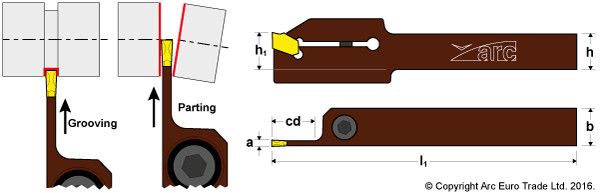

In the OP the top tool is for parting only, with inserts for same. They do not like taking small cuts. In my experience anything less than 4 thou per rev and they chatter.They can be used to turn grooves, but it's not a nice experience, only done it once. If I need to cut an accurate groove I use a HSS toolbit as they don't chatter with fine cuts. However, if you get the conditions right the insert parting tools work well:

The steel part bottom slighly left (~2-3/4" diameter) was parted off with an insert parting tool with no fuss and an excellent finish; better than I get for normal turning.

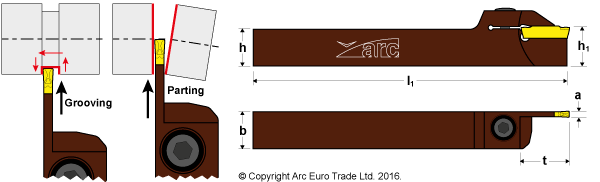

The lower tool in the OP can take a multitude of inserts and has a different, more positive, clamping arrangement, rounded inserts are particularly suited to profiling, like this:

The profiling cut isn't pussyfooting about, note the blue swarf! If I remember correctly DOC was 20 thou and feed 8 thou per rev and a spindle speed of 800rpm. And yes, I know it's a Dickson toolpost, but that's what the copy unit came with.

My modus operandi for parting off with an insert tool is have no more sticking out than needed. My toolpost automatically sets perpendicular to the cut. In the above picture you can just see the radial "gear"on the left that aligns the normal toolpost. Lock the topslide and tighten the gibs and lock the saddle. Part off under power with a minimum of 4 thou per rev and always coolant except for brass and cast iron. Spindle speeds are normally in the mid hundreds of rpm.

Andrew

Pete Rimmer.

Hi Robin

Hi Robin