Bit of progress on the fabricated GH Thomas dividing head – its first job used in anger, to make the secondary "micro adjustment" worm wheel for itself. For the main wormwheel i have used an old Myford 60T change gear. This was used to direct index and cut a 60T secondary wormwheel for the micro-adjustment, an extra accessory that allows fine adjustment down to 1/1000th of a degree, and will be used to make the indexing plates on the dividing head itself with great accuracy.

Anyhow, here is the set up, half-completed dividing head set up on the vertical slide in the lathe, with DP32 gear cutter on arbor in the chuck. The vertical slide is swung around at the helix angle of the worm, 4.2 degrees.

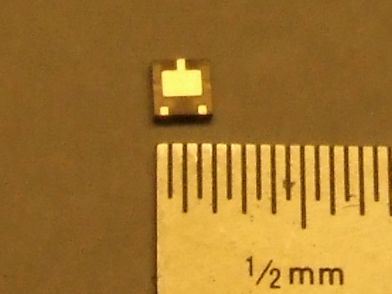

Not a true helical gear, more a straight cut gear with the teeth at a slight angle, seen here

So that the worm itself, also turned up on the lathe, sits straight in relation to the wormwheel instead of offset by the helix angle of 4.2 degrees

On the main wormwheel, made from the straight cut Myford gear, I thinned the thread on the worm so it could be turned that 4 degrees to straight. As it is point-contact only, and not used for transmitting power, it works OK.

So, quite chuffed to use the dividing head already! In fact, using the jury rigged plunger on the teeth of the 60T gear, I can direct index pretty much all divisions one is likely to use for ordinary workshop use, including 2, 3, 4, 5, 6, 10, 12, 15, 20, and 30. Eight could be done by making a notched plunger to allow half-tooth indexing.

Putting the finishing touches to the micro-attachment right now so will post some fully assembled pics when it is done, showing how the two wormwheels work together.

Currently also trying to find some 5/32 plate for the index plates. I think I will have to turn them down from 1/4" plate, which makes it a much bigger job, on top of cutting the round blanks by hand then to be followed by drilling the 10 million holes using the micro-adjustment for indexing.

All this so I can make the dozen or so tiny gears for a working model vintage Harley engine!

JasonB.

JasonB.