Posted by JasonB on 08/11/2016 17:32:22:

Did you use separate cutters for the roughing out and then a small bull nose to do final shape and leave the radius in the corners?

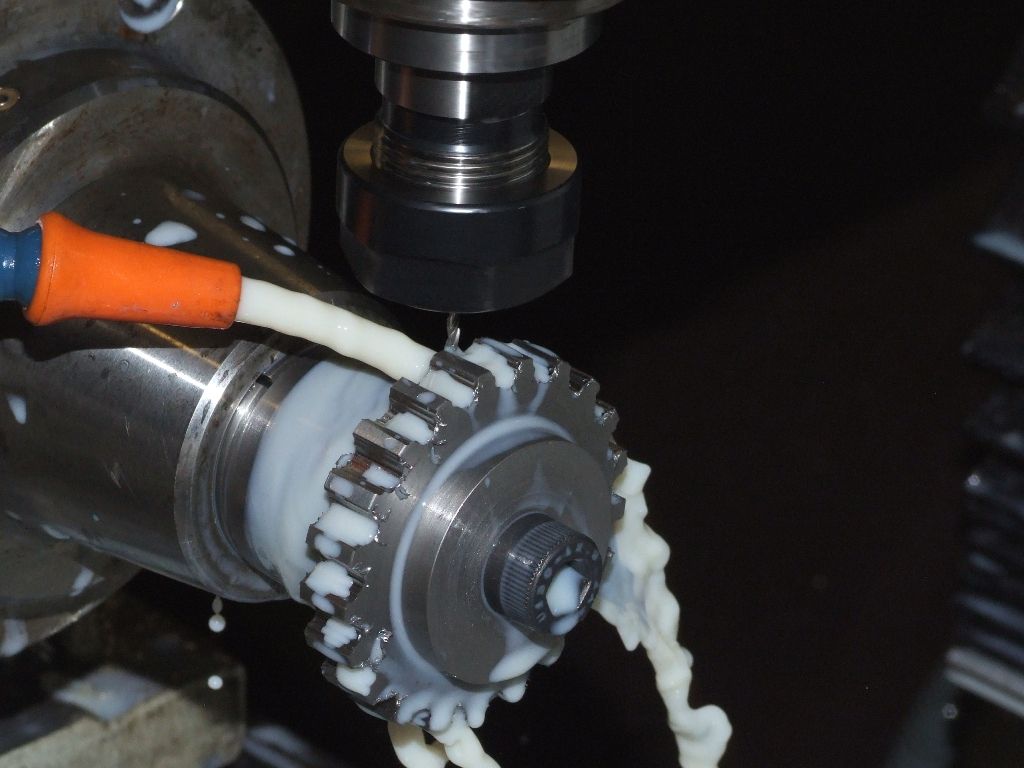

That was the original intention. Rough out with a 3mm ballnose cutter, then swap to a 2mm ballnose to finish roughing. The lower part of the tooth space is a little under 3mm in width so one cutter can't do all the roughing. Finally the 2mm cutter is used to do a profile pass with a small stepover. Since I designed the gear from scratch the radius at the root was conveniently chosen to be 0.04", so a 2mm cutter would be fine.

In the 2½D CAM functions there is an option to cut each feature to final depth before moving on, or alternatively cut all features to the same depth before moving to the next level. That doesn't seem to be an option for the 4th axis. It's an area where my CAM program is a bit weak.

I had some issues with the CAM system not doing what I wanted, and the generated G-code not following the displayed toolpath. By the time I'd sorted it all out I had the 2mm cutter doing everything. This is a one off gear and I couldn't be bothered to go back and use different cutters for roughing and finishing. I just left the CNC mill to get on with it while I sat in the study and did a days paid for work.

The method apparently used by Gearotic would be a better way of doing it. However, Gearotic simply doesn't work for me; I've just tried it again and within a minute it had crashed. Second time around I did get to look at the G-code generator. But it's very messy, and for the life of me I couldn't see a button that would actually generate a toolpath or G-code?

As for the maths, it's hardly complicated, just secondary school geometry. I was going to say complex, but I can't see how complex numbers would come into gear design. Unless the gears were conjugate of course (mathematical joke).  As and when I make another spur gear on the CNC mill I'll write my own G-code; it isn't difficult to work out the geometry and thus toolpaths..

As and when I make another spur gear on the CNC mill I'll write my own G-code; it isn't difficult to work out the geometry and thus toolpaths..

Andrew

JasonB.

JasonB.