On

15 April 2024 at 21:10 Bazyle Said:

You do know it doesn’t matter, not even slightly?

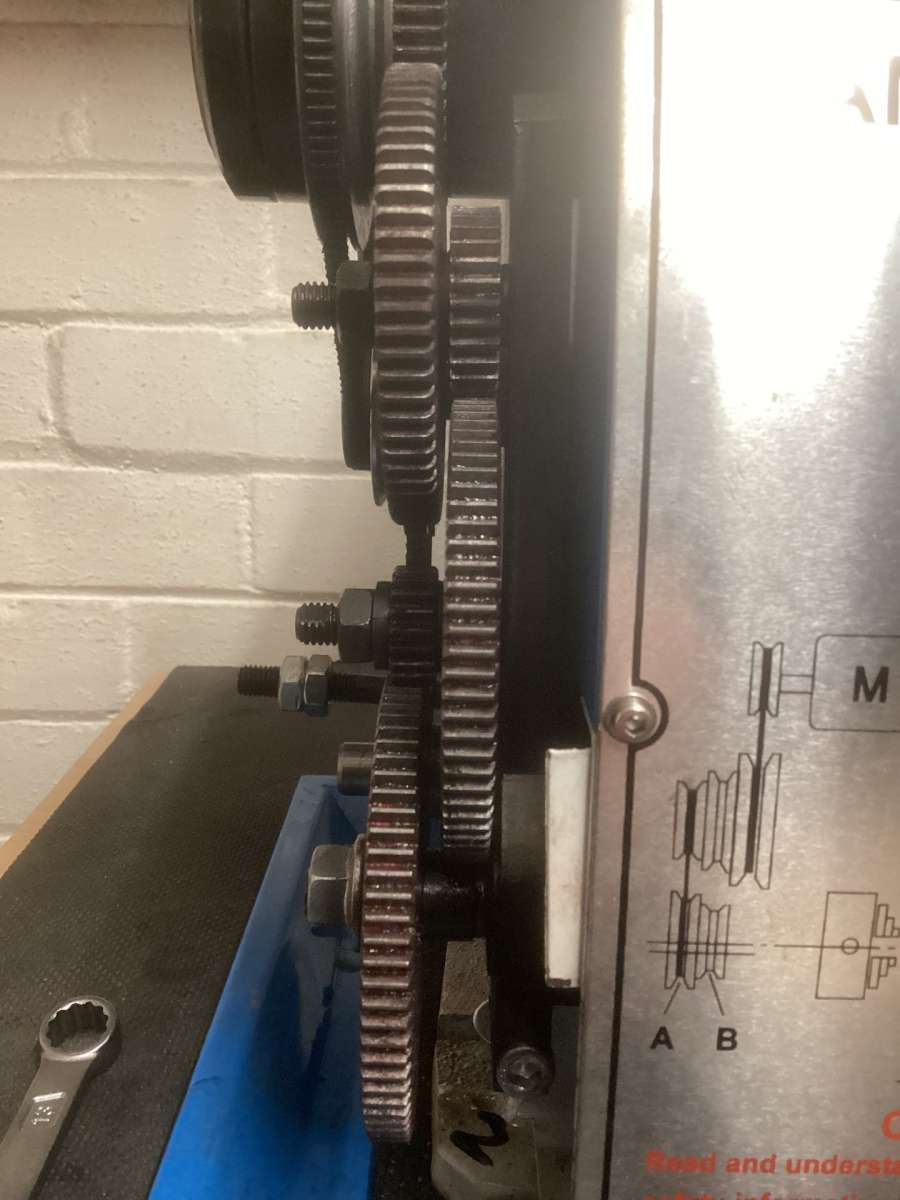

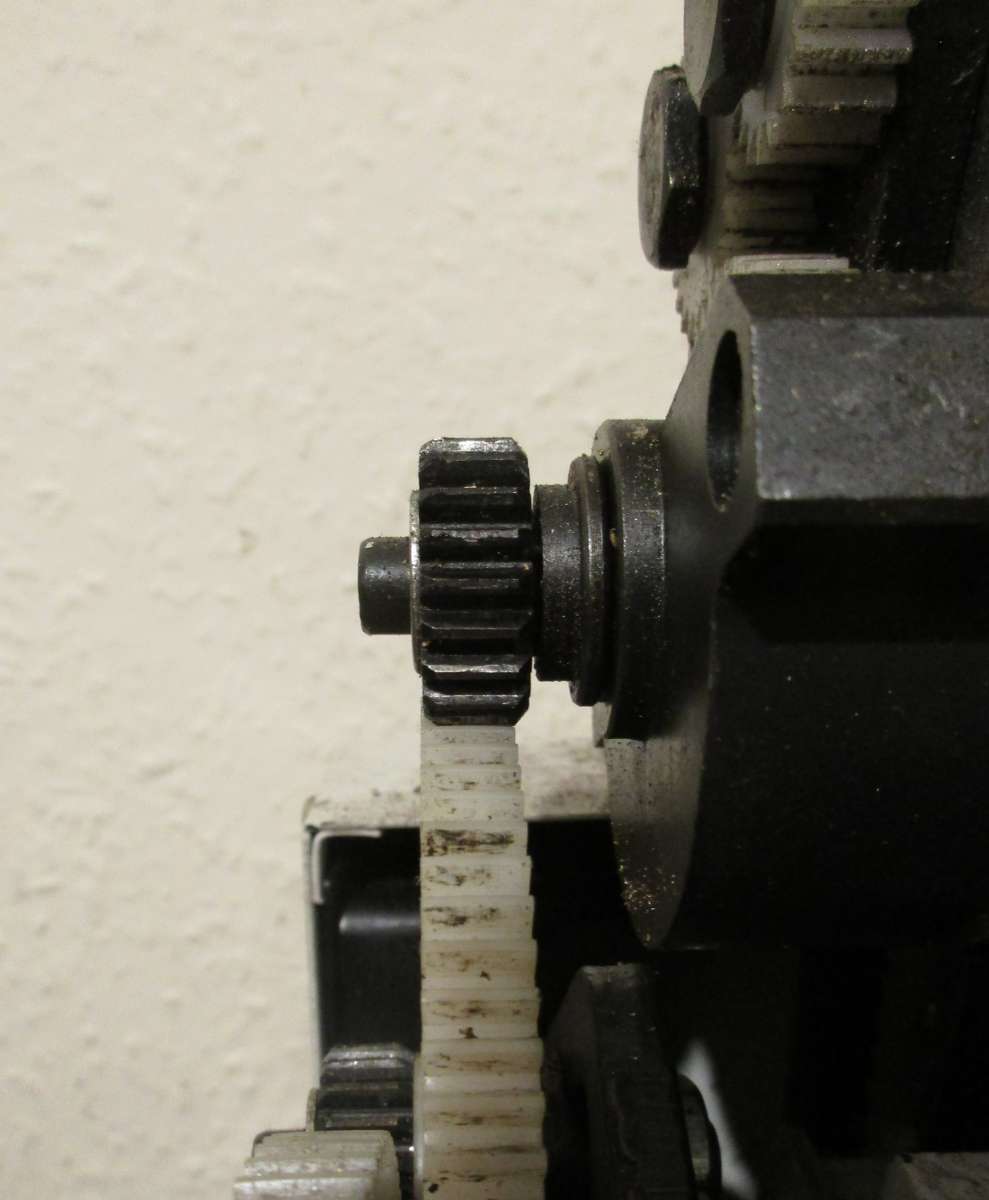

I’m unsure. That’s why I said on the one hand it was a visual issue, and on the other hand referenced my recent milling machine issue, where a vertical gear misalignment definitely did matter. Whilst there may be no current running problems with the gears, does the future likelihood of uneven wear across the teeth of the gears not matter, even slightly?

Probably not. The gears in a mill are part of the drive-train, relatively small, fast spinning, heavily loaded, and subject to shocks. In contrast, the gears in a lathe banjo only have to drive the lead-screw, which, being a worm, has a massive mechanical advantage. Thus banjo gears have a relatively easy life unless there’s a crash, when they’re often saved by a shear pin. I’ve never heard of a banjo gear becoming a problem due to uneven wear, probably because it would take years of hard-work to cause a malfunction.

I had a similar alignment problem on my WM280, and it took me a while to notice that the supplied washers aren’t identical. The difference isn’t obvious at a glance, nor is it mentioned in the manual, but the gears only align properly if the right thickness washers are put where they need to be. Try taking the banjo apart and having a good look at all the parts and how they fit together to make sure there isn’t a slight assembly problem due to washers or similar.

The banjo on my mini-lathe was a fiddly chore, but difficult to get wrong. That on my WM280 is much better, except it’s easy to misplace washers unless alert to them. On my lathe the size of the resulting problem varies depending on the ratio, either not mattering at all, or looking obviously misaligned, or grinding two gear faces together. Only the grinding is a ‘must fix’. Your lathe may be different again – the devil may be a detail of the banjo design, as I say not mentioned in the manual!

Dave

Bill Phinn.