Steve,

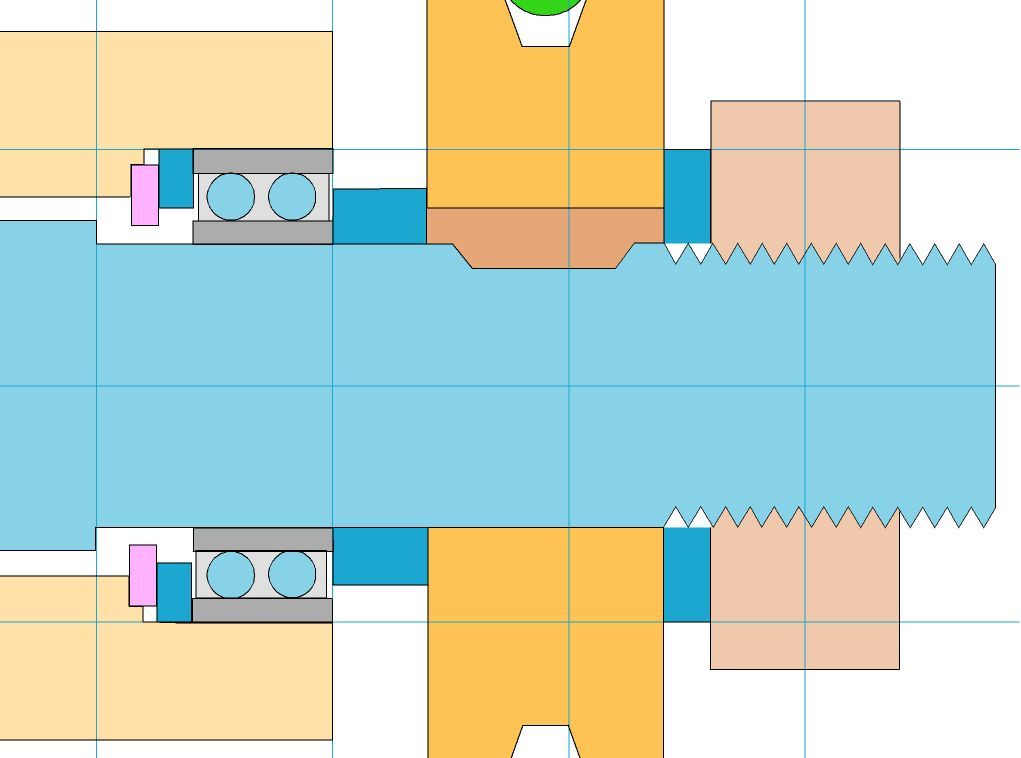

I don't believe 'actual' end float is needed – Rather design the shaft/pulley/end nut so that you can apply a small pre-load, and lock the end nut in place with maybe another nut – lock-nut style. And try to make the spindle shaft and the spindle housing of the same material so that thermal expansion coefficients are close to the same – that way the bearing will be treated more kindly.

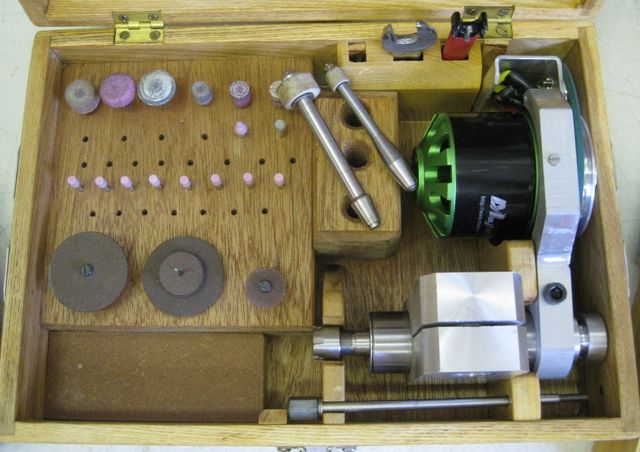

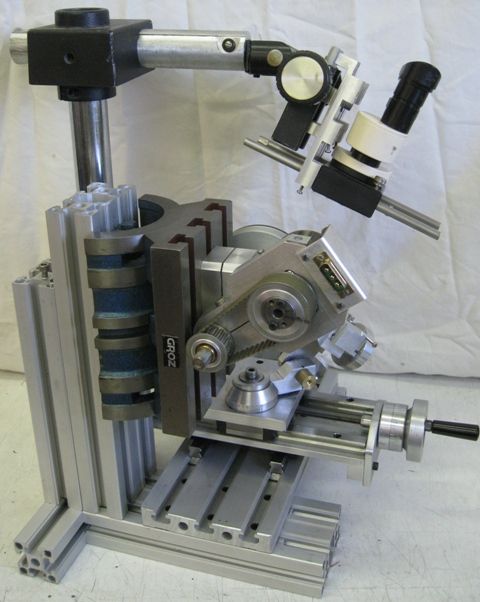

Also, nothing wrong with your pulley/belt style – I used that on tool post grinders – internal/external, spinning up to 14,000RPM, with a brushless drive motor of up to 800watts..The belt is a sort of neoprene – 6mm diameter, from RS-Components, and you cut to length and heat-join the cut ends. Works very well, and is cheap to replace – mine has lasted around 120 grinding hours…

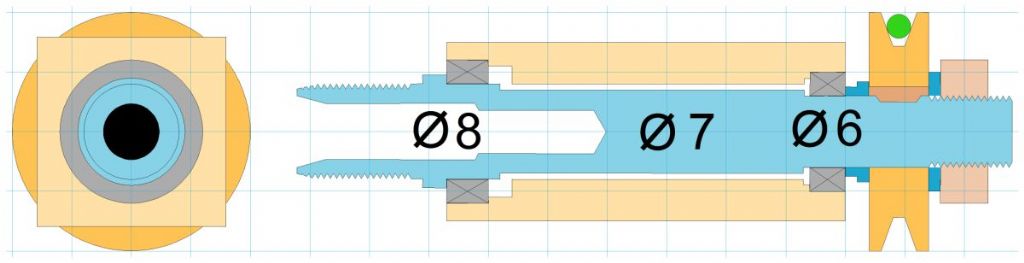

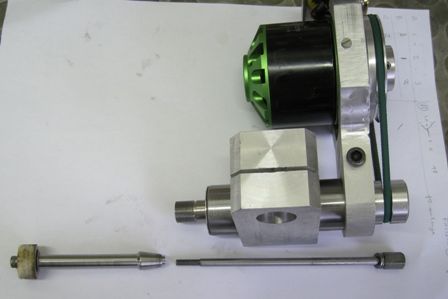

The spindle takes ER11 collets, but has a hole through for a draw bar that pulls tight extensions to which are fitted grinding wheels, as in these photos. The extension I make up as need for any special wheel – inner grinding or outer with bigger ( 50mm diameter) wheels, etc. The extension where the draw bar pulls is a male ER11 collet fit. You may be able to fit a 3mm or 4mm draw bar to your design as well?

The brushless motor on this unit is 500watts max – 60mm diameter, 70mm long, running of 36volts DC

I.M. OUTAHERE.

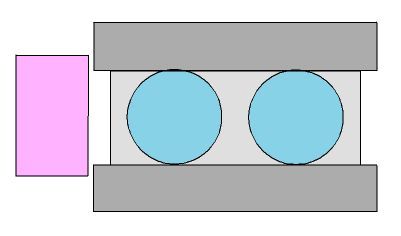

; the second one's OD contacts the step in the housing bore, as above. As used by Emco in the Unimat headstock – two, with angular-contact bearings in the early Unimat, 4 pairs, back-to-back*, with deep-groove bearings in the Unimat 3. You need a reasonably firm spring to resist the possibility of the spindle moving axially, should it ever be loaded towards the workpiece by, for example, a drill grabbing in brass.

; the second one's OD contacts the step in the housing bore, as above. As used by Emco in the Unimat headstock – two, with angular-contact bearings in the early Unimat, 4 pairs, back-to-back*, with deep-groove bearings in the Unimat 3. You need a reasonably firm spring to resist the possibility of the spindle moving axially, should it ever be loaded towards the workpiece by, for example, a drill grabbing in brass.