Hi guys, sorry for another thread. There is so much I don't know, yet trying to get my head round, despite searching for the answers myself.

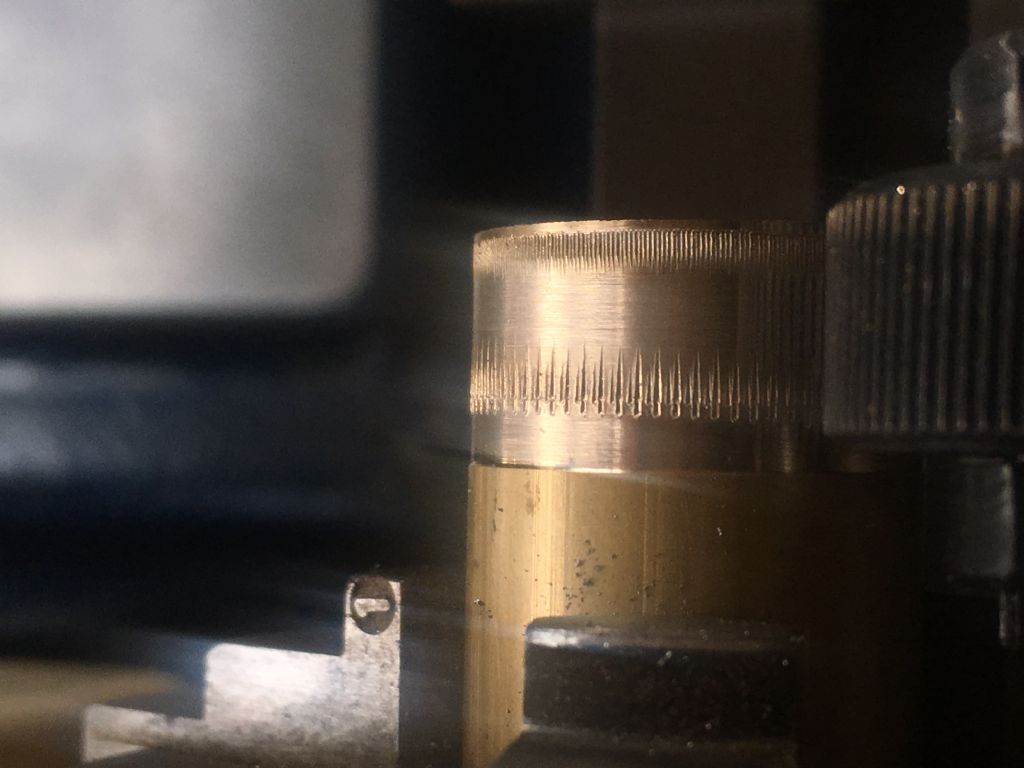

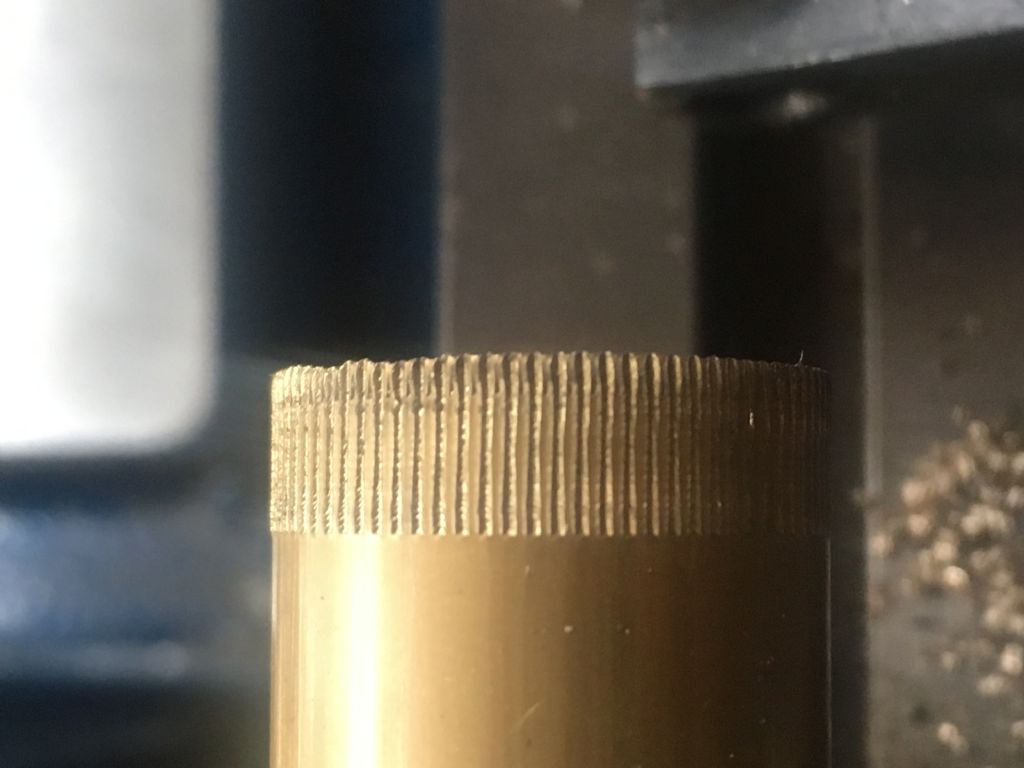

So I am looking for a knurling tool for my Cowells ME90, The manufacturer sells their own single wheel type with 6mm shank that fit their tool holders.

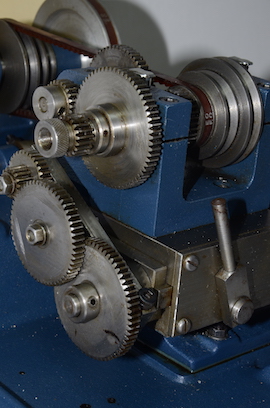

I have also seen these double wheel types on eBay that I thought might be a bit better and cheaper, but they have a 10mm shank which is too big for the tool holders I own.

Do I buy that and try file the shank down a few mm? (if my files can handle that type of steel?)

Buy a tool holder that accepts slightly larger tooling? If I can I even do that, are all the dovetails on those tool posts universal and interchangeable?

Just buy a single wheel type from Cowells?

or something else?

Not really in a position to make my own just yet which I assume will be a good option down the road at some point when I have more experience and tools.

Thanks

Edited By Steve Sherlock on 06/08/2018 15:29:38

Edited By Steve Sherlock on 06/08/2018 15:30:30

Neil Wyatt.

Neil Wyatt.