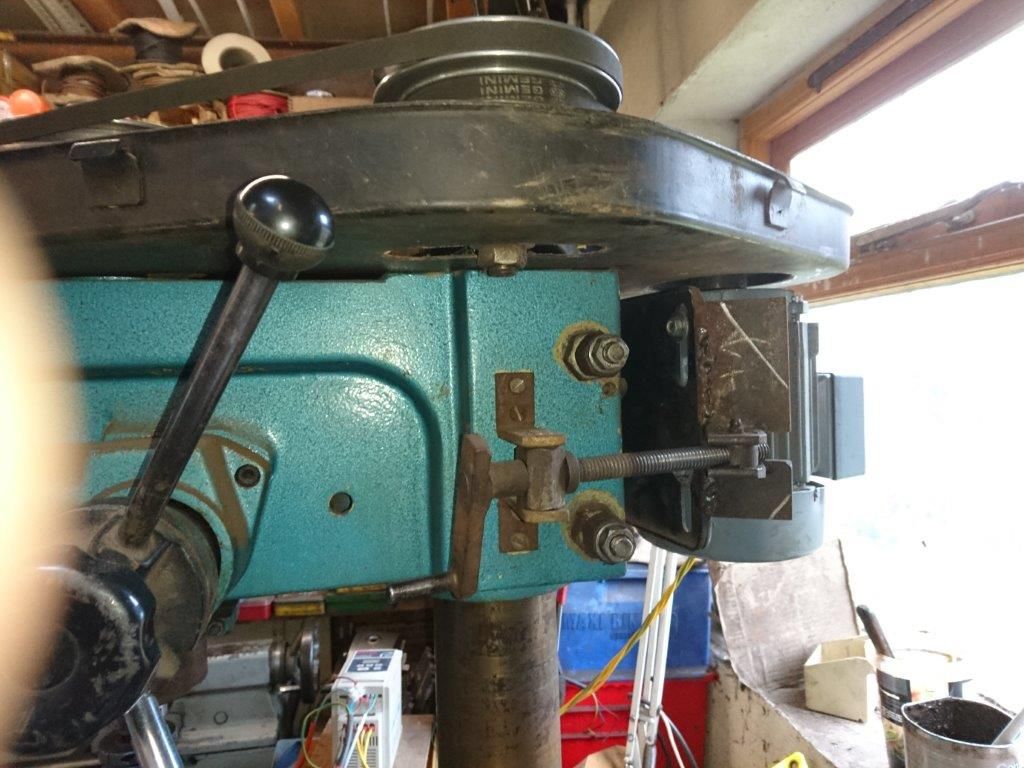

Simon, I have to agree that belt tightening is not very clever on these machines if yours and mine are anything to go by. The motor belt I can get reasonably tight by pushing hard on the motor whilst doing up the crude adjuster; that was an unexpected bonus of having to resite the motor to the RH side of the mill/drill. The top belts from intermediate pulleys to spindle pulleys are a pain – having to stand on a stepladder and slacken two socket head bolts, try and hold the intermediate pulleys with sufficient tension whilst tightening one of the socket head bolts is awkward to say the least. Your excellent belt tightener idea would be very useful on this section of belt drive Simon. I get a bit of vibration from the belts but very rarely belt slip, and I can see the motor is vibrating a little too. I am sure a 3 ph motor will not vibrate nearly so much and will run a lot smoother. A 3ph motor with a VFD will make changing that belt and re-tensioning a greatly reduced occurrence, as you have pointed out.

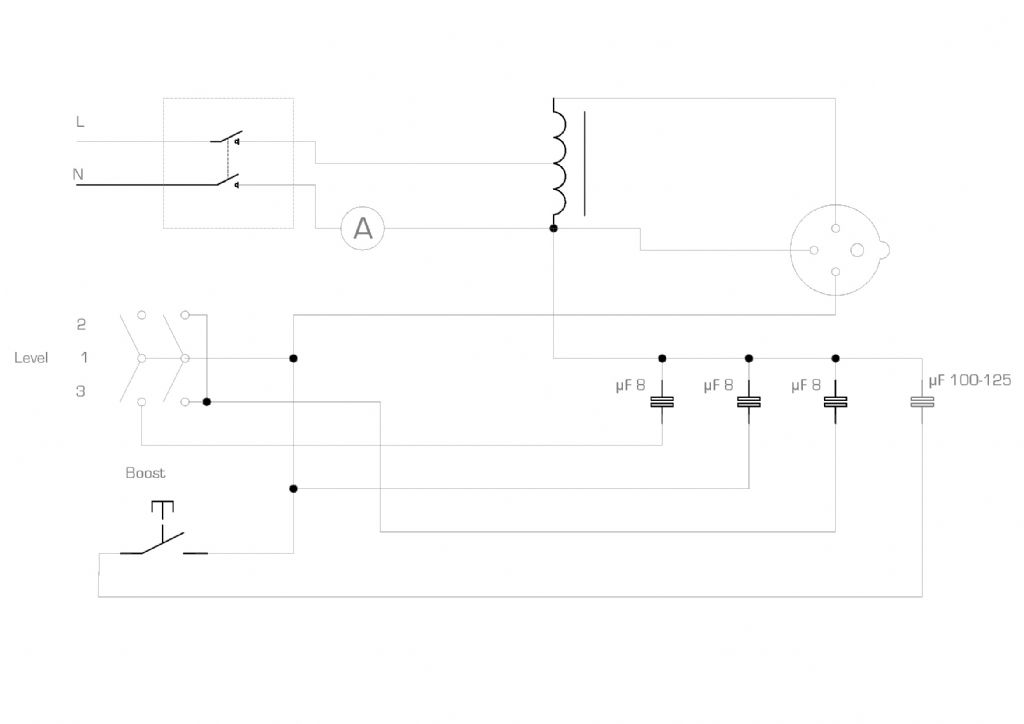

Do you find that the 0.75kw motor on low Hz, say between 10 and 25 Hz, lacks torque when doing meaty cuts Simon? Because with respect to motor size, my thoughts of yesterday are now back in for re-negotiation, and part of my worry is low Hz torque with the 0.75kw motor.

The motor that would fit without any alterations would be the 1.5kw motor (I'm looking at TEC motors). But that is double the original 1ph motor and maybe a bit of an overkill. The 0.75kw motor would match the power size of the original and would be way smaller physically, which would be nice, but would it have the torque at low Hz running speeds? The 1.1kw motor is more similar sized physically to the 1.5kw motor, would presumable give more low down Hz torque, but would need the mounting feet holes in the brackets altering, which would not be a problem if one had another drilling machine or has faith in the ability to drill 12mm holes accurately with a 3/8" electric drill and a 1/2" battery drill which is all I have available in the absence of the mill/drill; not insurmountable, just blooming awkward. Plus, there is a cost element to factor in, like the 1.5 motor is £37 more than the 0.75kw motor, a not insignificant sum.

So, I'm back to, do I go with 0.75kw and risk insufficient low Hz torque, 1.1kw and buggar about with drilling holes or 1.5 kw, overkill and £37 poorer? If money was no object it might be an easy choice in one way, but would it be the right one? Perhaps I need to speak to TEC after Christmas and see what their views are on running their motors on VFD's at low Hz are re torque. One thing I do like about TEC motors, amongst others, is that the feet can be relocated 180 degrees around the motor body to move the connection box to the best, or least awkward, place, which will help me and is not available on the 1ph motor fitted.

Chris

Edited By ChrisH on 22/12/2017 15:58:13

Clive Foster.