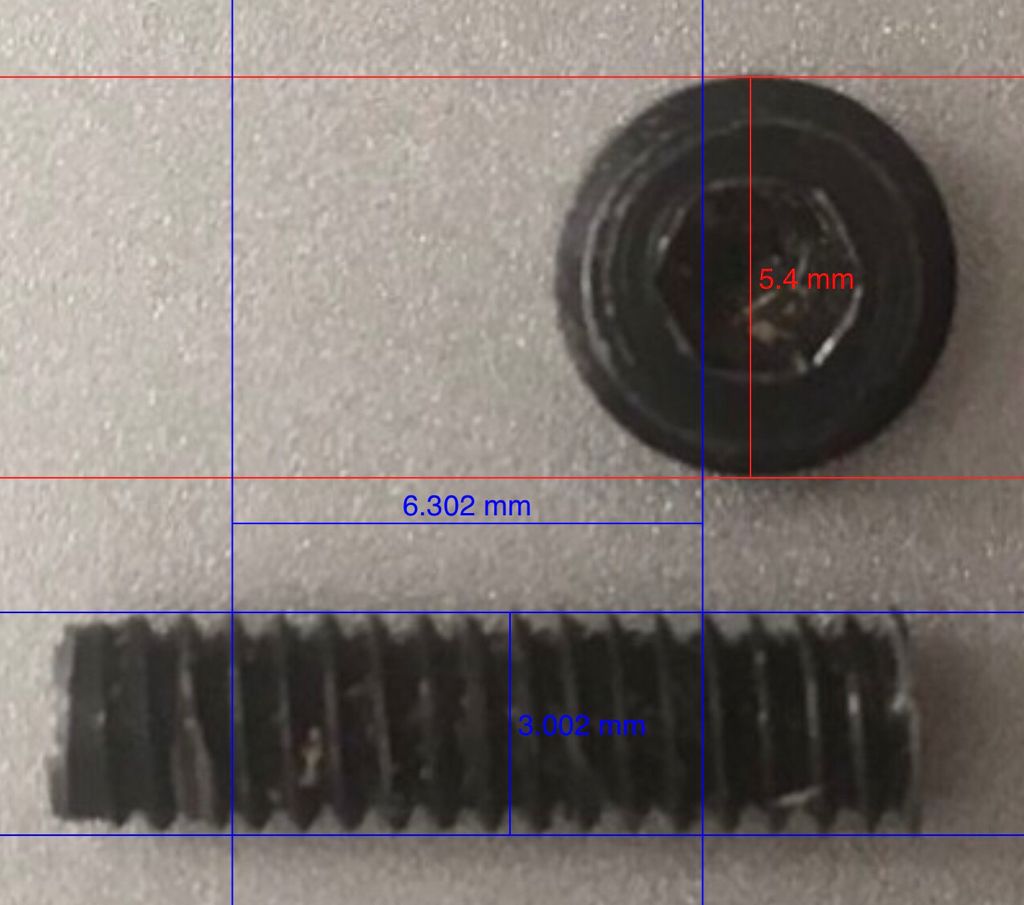

Without benefit of Michael's careful measurements from a photo, the thread could be either 24tpi or metric 1.0. The difference is small – 24tpi is M1.056 and 25.4tpi is M1.000

I 'd make a test piece as Roger suggests.

As my lathe is metric I'd try M1.0 pitch cut into a bore 21.0mm internal diameter. The thread needs to be about 0.61mm deep.

If I owned an Imperial Lathe, I'd try 24tpi. The thread depth will be much the same, say 25 thou, and the bore 0.827 inch diameter.

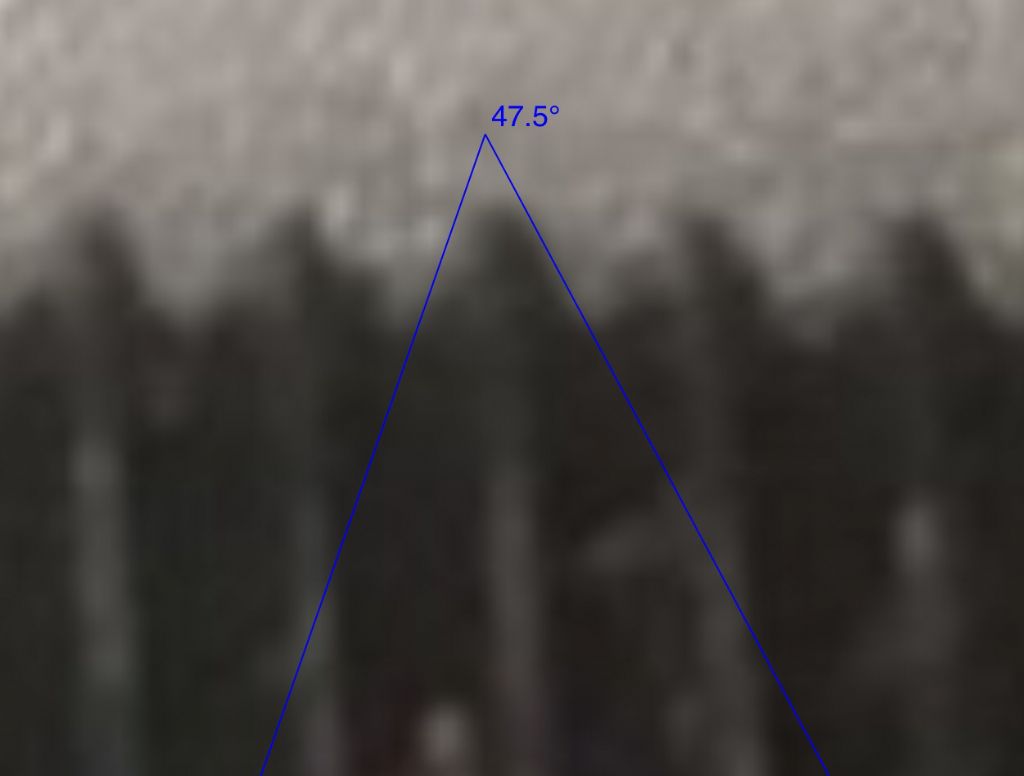

Decide between 55 and 60 degrees by offering a metric or imperial thread cutter up to the carb, and use which ever is closest.

Offer the test piece up to the carb and see how well it fits. I agree with Tony – I think any combination of metric, imperial, 55 or 60 degrees should be close enough to screw together. Even with the wrong pitch and thread angle, you should be able to get a good tight fit by removing metal slowly as the thread approaches the theoretical 0.6mm deep and stopping as soon as the carb screws in.

The main challenge is making sure the joint doesn't leak petrol. My guess is the original was fitted with a washer.

Dave

PS Grateful if someone else would confirm the dimensions. Maths and I aren't best friends…

Edited By SillyOldDuffer on 31/08/2018 21:16:22

SillyOldDuffer.