Hi Brian,

You have a relatively mass produced clock sadly of no great value. However, I would be as keen as you to get it running again and overhauled.

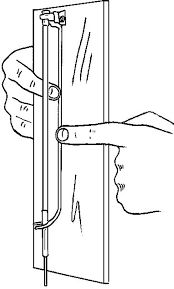

In my youth, a number of striking clock mechanisms (of no particular worth) were left in a tub of petrol, and the petrol squirted through all pivot holes with something like a turkey baster moving the pivots for and aft.

Later, other valuable movements were treated better and more thoroughly in subsequent years, and worn pivot holes rebushed, and damaged pivots replaced. But the tub of petrol approach is not to be dismissed if all pivots show no play in the pivot holes.

I can cope with English movements and their striking, and Longcase clock movements and their striking.

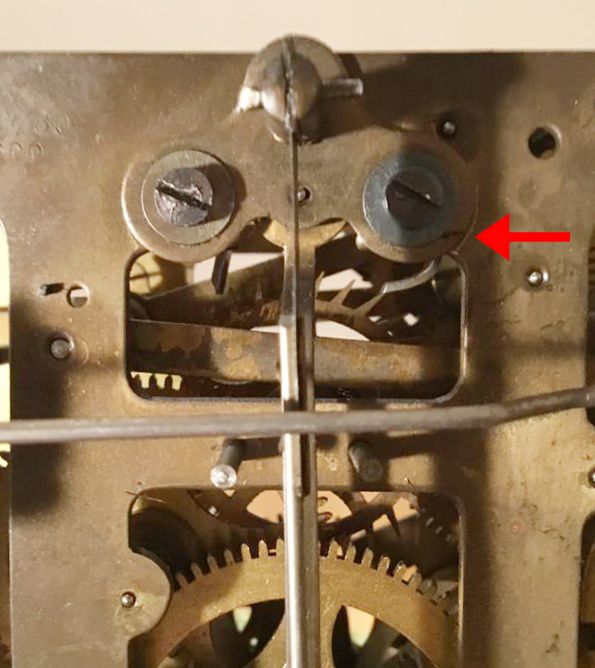

However, I failed miserably with an American striking movement on a rather nice family heirloom, and I failed to re-assemble the striking mechanism correctly after repairing some worn pivots and pivot holes with the clock completely dismantled. It runs ok and keeps good time, but I do not wind up the striking mechanism as it goes mad. Your project has inspired me to have another look at it after some 23 years.

But I think my point is that in these cheaper foreign movements is to be very careful what you do so far as dismantling and the striking mechanism. Others far more expert than me will no doubt give you far better advice.

Cheers,

Julian

Bodger Brian.

Bodger Brian.

.

.