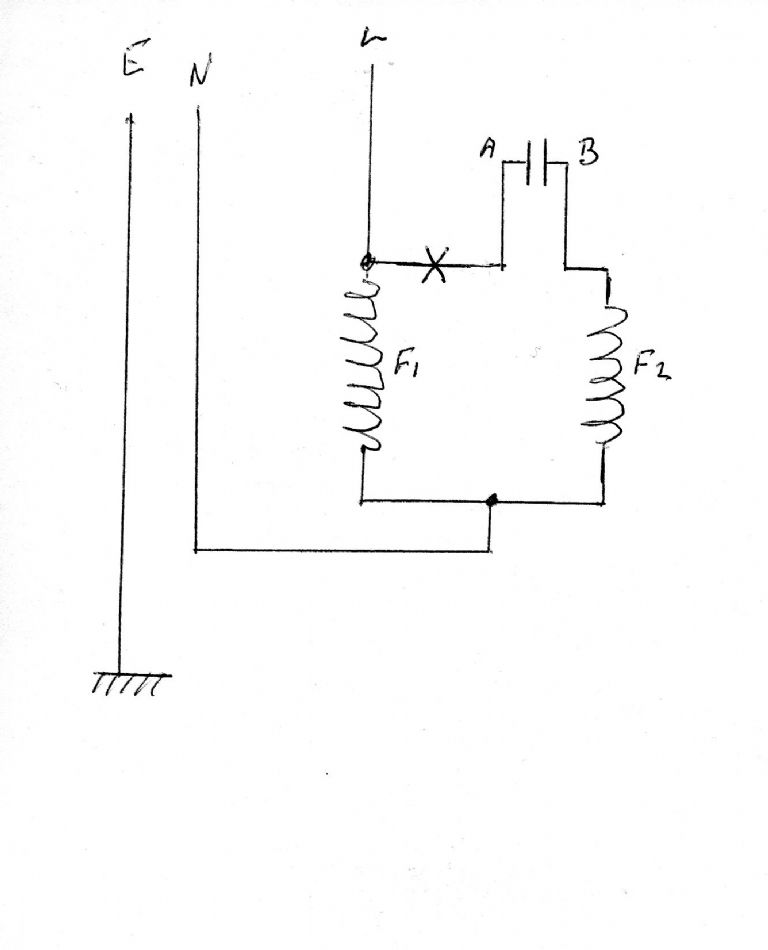

Hi Vic. I don't know how you are with electrics, so I've tried to keep it simple. It all depends on whether the motor has an internal centrifugal switch. If it has, it's a capacitor start machine, if not it's a capacitor run motor. The sketch below shows a capacitor run motor. A capacitor start motor would have a switch where I have marked X.

If it is a capacitor run motor it is dead easy to reverse them. Make sure the power is OFF. Dis-connect the live feed from the NVR to the motor and make sure the loose end is well insulated. Run a new live feed from the NVR to the common terminal of a suitably rated 2way switch and wire the switched outputs to either side of the capacitor (one to A the other to B). Operating the switch should reverse the motor but DON'T DO IT WHEN THE MOTOR'S RUNNING. You wouldn't select reverse while you were driving down the motorway.

If there is a centrifugal switch fitted, then I'm afraid you have problems. To reverse the motor you need to reverse the live and neutral connection to ONE of the field coils. This means you would need to open the motor and find the neutral ends of the field coils, separate them and bring them out on individual wires. You would also need a double pole change over switch.

Hope this helps.Anthony

Anthony Knights.