Hello to all fellow machinists and modellers!

My name is Joe, and Iive 50 meters from the edge of the Atlantic Ocean, in Swakopmund, Namibia. Now sort of retired, from a Career in Electronics for Jets and Helicopters, and now doing lots of modelling, Ham radio and small Unmanned Aircraft.

On the far left, a DRO fitted Emco FB-2 Mill ,then the drill press, a band saw, then another Emco FB-2, converted to full CNC, and then on the right the large (1000mmx900mm) Router.

Big Mill

Large Tool and Cutter Grinder

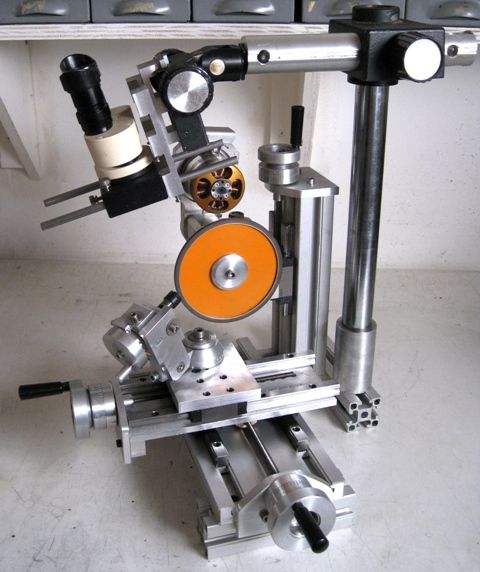

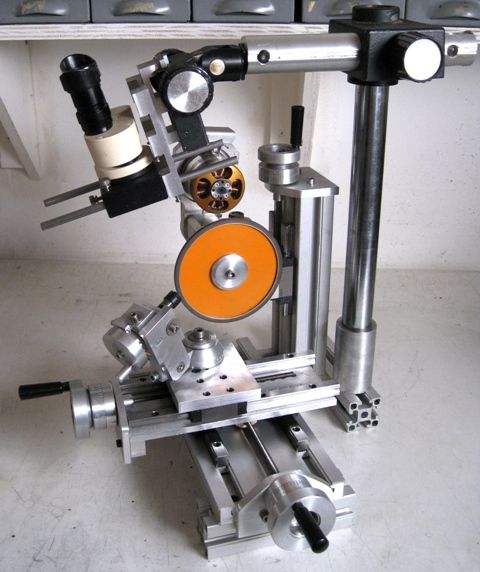

Small T&C Grinder

Small Router / Engraver for PCB's

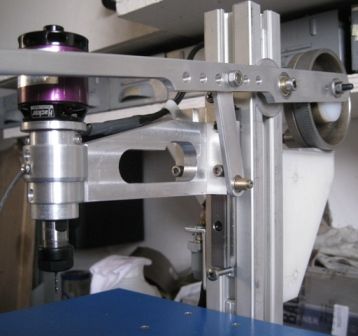

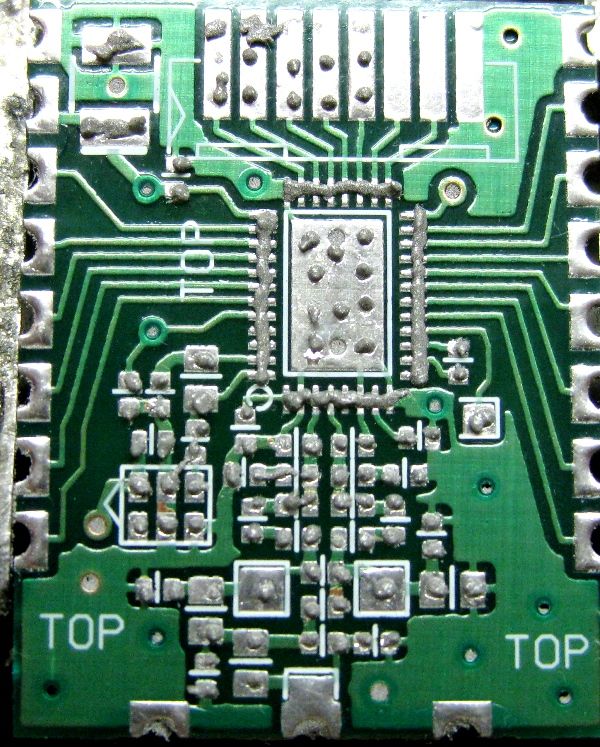

Engraving a PCB – Pad spacing 0.5mm using a floating spindle head

Emco Maximat V10P Lathe – My Baby..

One of 3 Emco FB-2 Milling machines – this one re-fitted with a Jones and Shipman Direct Drive spindle and Three phase speed control Inverter.

Small Sensitive Hi-Speed Drill – up to 25K RPM, using RC brushless motor and purpose made ER11 Collet drive.

Solder Paste Dispenser I made to extrude solder paste onto the PCB for reflowing – Uses an Arduino processor to generate pulses to the stepper motor on the handheld extruder, which presses a plunger onto the paste in the syringe and extrudes out a fine nozzle. The left hand hold a pressbutton which when pressed lets the stepper advance an adjustable number of pulses, squeeze paste out and then quickly retract more than advanced to stop the paste, making a small dot of paste , from 0.3mm to 0.5mm diameter –

Strip down of the extruder, syringe and plunger. This unit fits into a heater ( see top right of previous photo) to heat the solder paste to around 35-40deg C prior to use, so the paste flows freely.

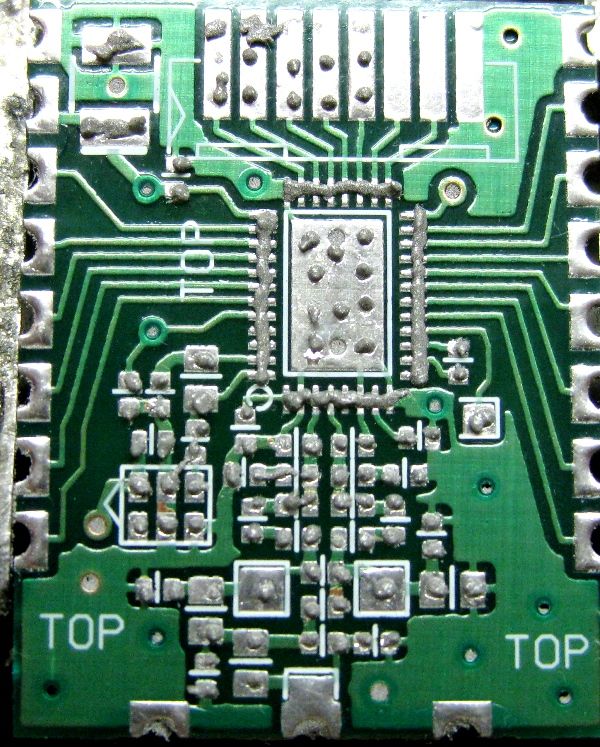

A PCB pasted – not done to neatly – just a test.

The smallest squarish pads are 0.6mmx0.4mm

Some Toolpost Grinders – Er8 and ER11 collets.

My Late Father-in-law's Career Tooling:

Lorch Lathe and lots of Watchmakers tooling, fully restored now by me.

The Electronics Shack

Radio ham stuff

V51JN/ZS6JGN

our small UAV's -2.4meter wingspan, 5kg, auto-launch,flight and auto-land.

Ian S C.