I have a question … ‘Are your chuck jaws through or case hardened?’

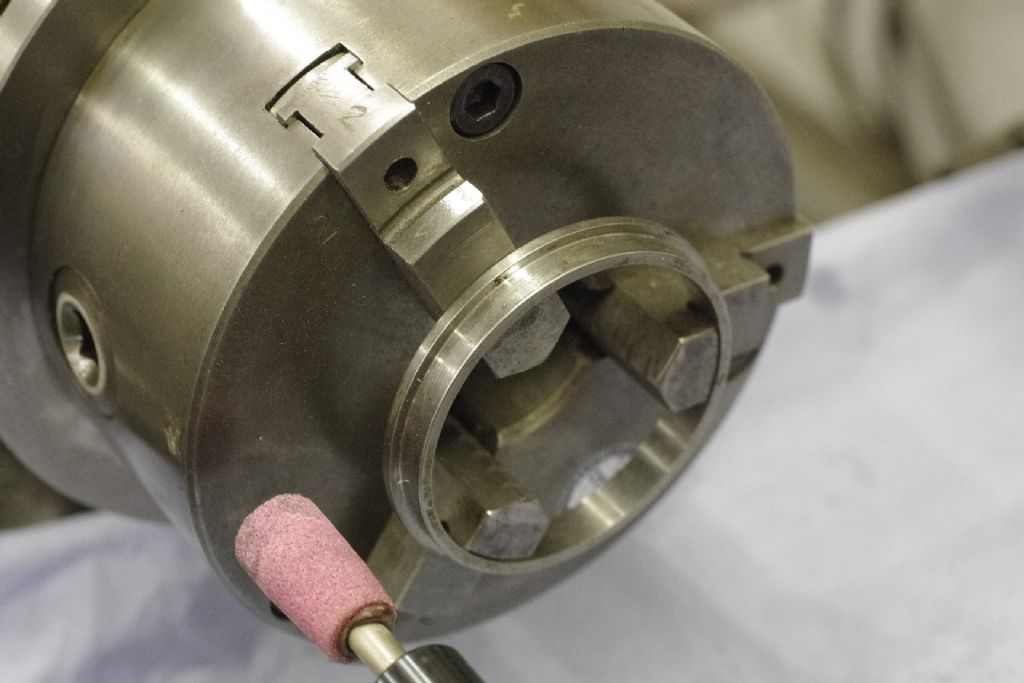

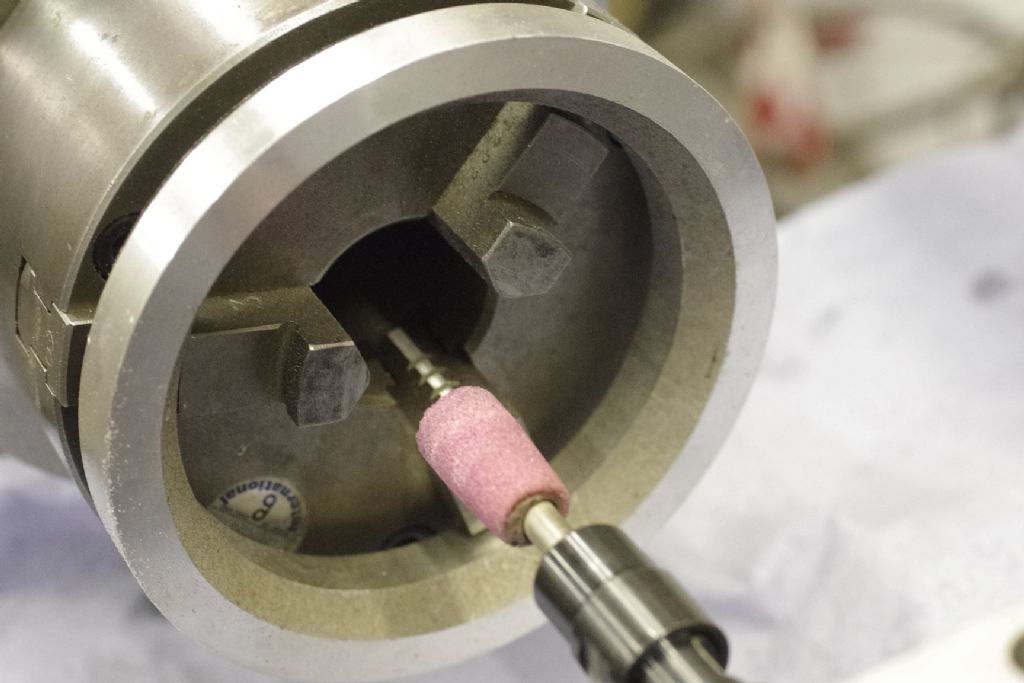

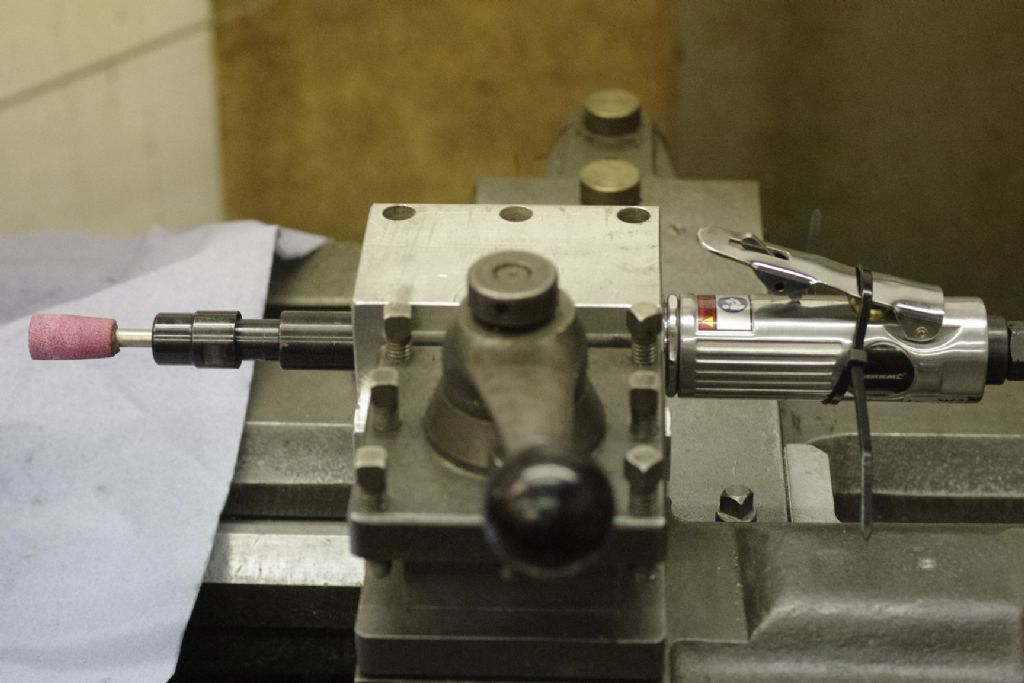

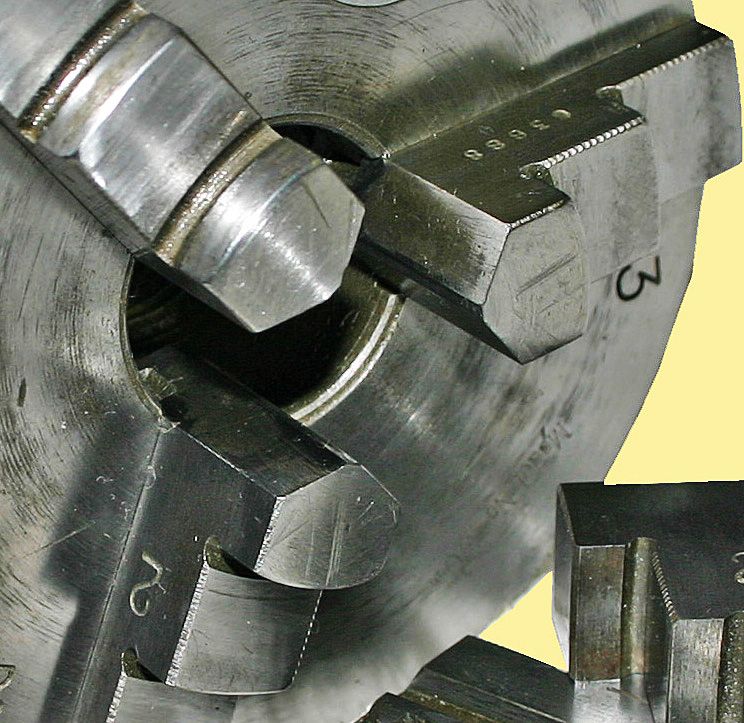

Applying lapping compound to a ½" diameter brass rod, I honed the gripping faces of the (outside) jaws of my ML7 Bernard three jaw.

At a slow spindle speed and the bar gripped in the ½" tailstock chuck, I slid the tailstock and the brass rod back and forth while occasionally adding gentle pressure to the jaws. I continued this process until there was a clean line from the front to the back of each jaw.

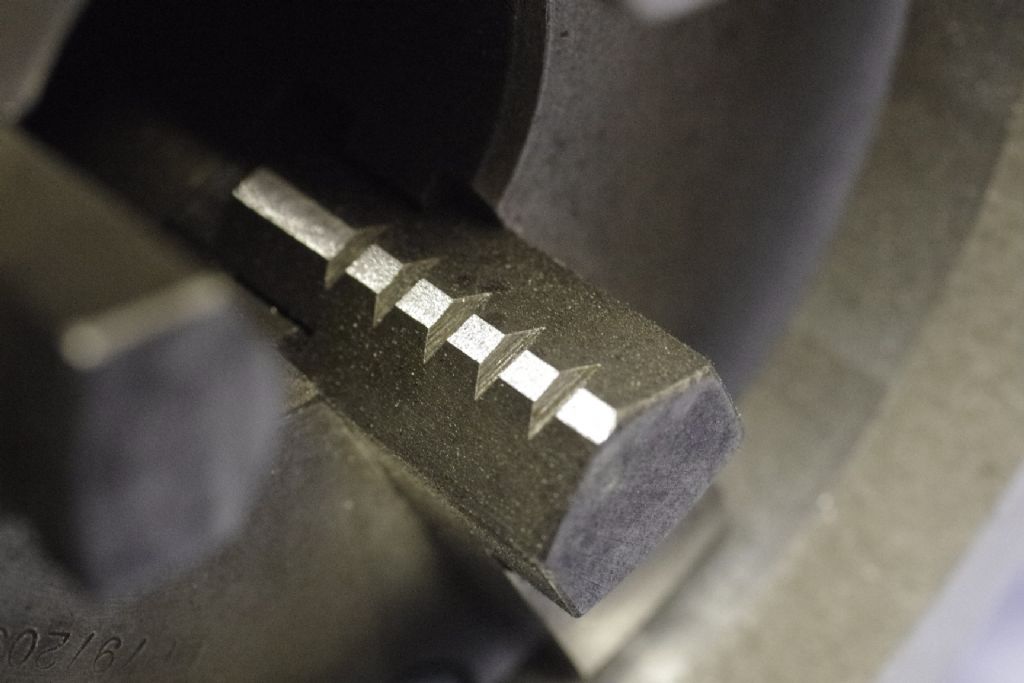

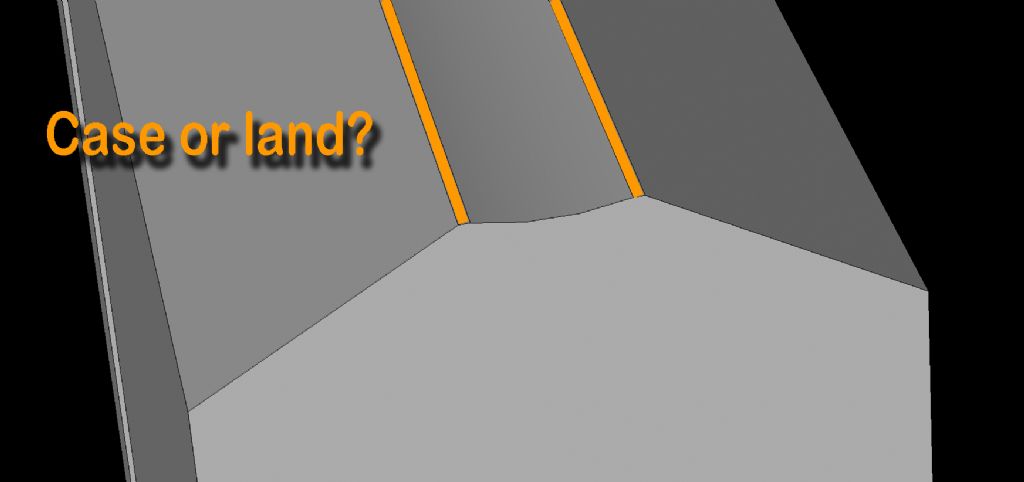

Later, (after much use) I noticed the appearance of a pattern on both the gripping surface of the jaws and marks in material e.g. aluminium. The imprinted pattern showed how the core material of the jaws had been impressed, while the ‘skin’ had remained less so.

While I have no direct photographic evidence, I found that the jaws were not through hardening but case hardened.

I have mentioned this elsewhere but as I recall no one responded, presumably because no one else had observed the same effect or that it is not important.

At a guess, the chuck was new and came with the ML7 between the 40’s and 50’s.

Any comments?

Sam

Hopper.