I'd guess you're pretty much sorted by now, Brian, but here's a slightly different approach. It's from a design by Graham Meek in EiM, November, 2013. In another thread about knurling tools, suggestions were made to the enquirer to the effect that his wheel pivot pins, which were retained by nuts, would benefit from them being fitted on the side away from the chuck, to both allow closer running of the tool to the chuck and minimise the possibility of a nut/chuck collision (sounds painful ). On my original version, I staked the wheel pins to the arms to achieve the same aim, but, of course, this precluded the changing of the wheels for different styles of knurl. I've recently bought a new QCTP and this encouraged me to revisit the knurling tool to improve it a bit. I milled off the integrated dovetail mount (for my old QCTP) and fitted a piece of 12mm x 12mm steel stock which fits in a standard toolholder. At the same time I removed the staked pivot pins and made up a pair of slimline clevis pins, retained with external circlips as shown below.

I've hunted high and low for the magazine, but fear it has been mislaid in our move back to the UK a couple of years ago. Anyway, I think that there would have been copyright issues with reproducing the drawings here, anyway.

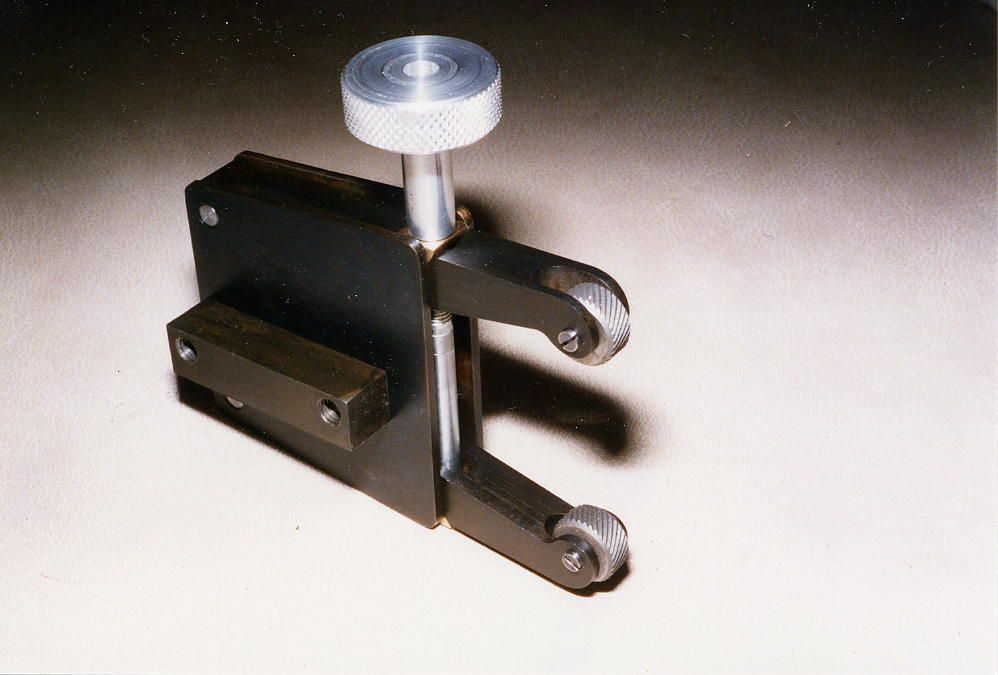

Above, the new mount bolted on in place of the milled-off integrated dovetail mount. (You can see the original in my album "Bedfordshire Workshop", should you feel so inclined! ) Also, the clevis pin retaining circlips are visible

The thinner-than-normal heads of the clevis pins, shown here. Changing wheels is much easier, involving just the removal of the circlips and then spending hours hunting for them on the garage floor after they've pinged off into oblivion. Not only me that happens to, surely?

More food for thought for you. Have fun, whichever design you choose.

John

Enough!.