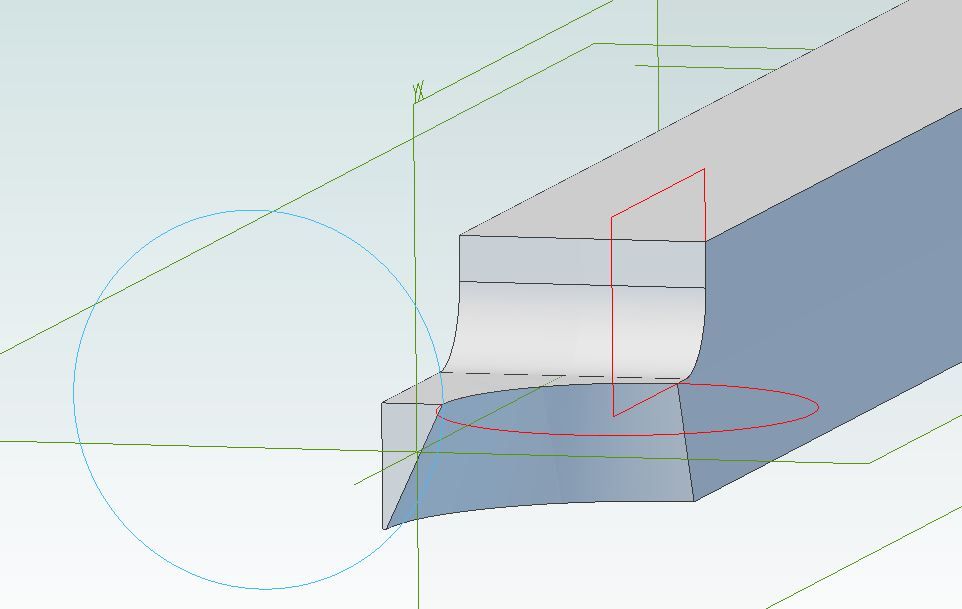

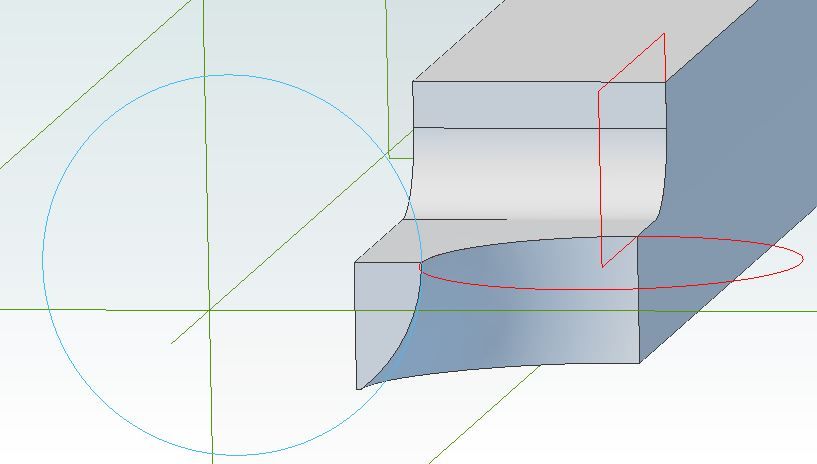

So far it seems I have to follow the procedure— bore the hole, cut the inner curve on one side, part off. Turn round & grip in chuck nice & square to the axis, machine other half of round. Undertake any smoothing out where the 2 curves meet to avoid any edges. Suppose some form of "lapping" but not sure quite how yet.

Mount onto a tapered male mandrel & drive up with a special nut that has a female part & square shoulder to make sure it stays square to the axis. Turn the outer groove, using a parting tool & Jason's step method, then need to either grind a piece of tool steel or purchase a circular tipped cutter smaller than the finished size to polish up. Finish off with a round file if there are any chatter marks.

Take it down the yacht club & say " look what i made- only cost me 30 bob in material" (yes I tell lies as well!!)

Insert somewhere above as appropriate —"Curse, throw it in the bin, have a cup of coffee & start again"

Edited By Sam Longley 1 on 07/09/2018 20:43:40

Sam Longley 1.