You might be nearer to an authority when you have made an adaptor lol. I don't see how a tool could be re machined for lots of reasons, least being the Herbert is larger than the int 30 ! ?

I machined mine slightly different to the forum method.

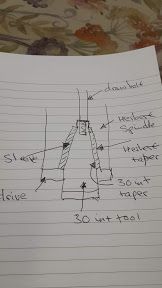

I chucked up a piece of material and bored it to a blued fit to 30 int tool , then turned outer dia to a rough size to Herbert taper.

I had a 30 int tool with a 1 inch spigot, used for a boring head, so I chucked some bar and faced and turned this to accept the 30 int tool,fixed 30 tool with the 4 mounting bolts drilled and tapped with it in the chuck.

I then used a short draw bolt to secure the half made sleeve for machining, removing sleeve to check blued fit into the Herbert

???…………………if I remember correctly.

All the controls on the machine should have plates showing the obvious ?

Good Luck with the project, not much more to add I think?

Pete

Edited By Pete White on 24/09/2020 18:10:09

Pete White.