Bit more info on what brand/model of lathe would be helpful, as would a pic of the thread indicator dial and the levers for the M11, A3 etc mentioned on the charts above.

But, first thing you need to do to turn metric threads is forget about TPI and conversions and so forth.

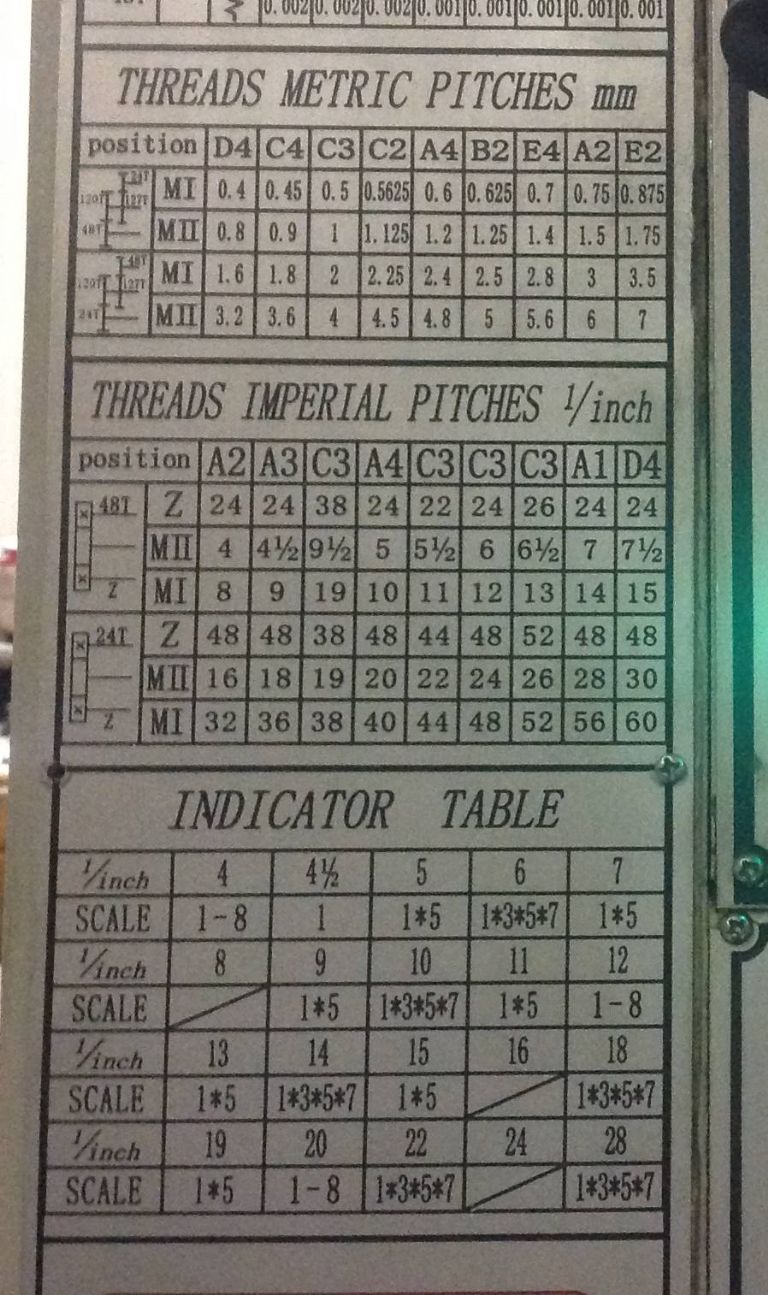

From the look of the chart you posted above, your lathe will do all that for you by a simple change of the change gears between the headstock spindle and leadscrew.

You need to set up the gears as show on the metric chart above, that is: 24T on the main spindle, a 127 and a 120 on the same stud in the middle, and a 48T on the leadscrew. The 120/127 combination is the "translator" to make your imperial leadscrew act like a metric one, by the magic of mathematics that is to arcane to get into here.

Once you have those gears set up as above, my best guess is you select the positions of MII and E2 with whatever selector handles/knobs match those. This will give you 1.75mm pitch, according to your metric chart.

Then don't use the thread indicator dial on metric threads. Keep the half nuts engaged at all times and run the lathe backwards to move the tool back toward the tailstock between cuts. The chart above looks as if the chaser dial is set up for imperial only, and it looks like you have an 8tpi or 16 tpi leadscrew, which is why no indicator number is specified for those pitches — you can use any number on TPI that are a multiple of the leadscrew TPI.

To turn imperial threads, your chart seems to show that you set up the gears with with either a 48 or 24T on the spindle and then change the gear on the leadscrew to value Z to obtain the desired TPI, as well as setting the relevant levers to A1, C3, M11and so forth as per the chart. The idler gear in between can be any size that fits the space. Its size does not affect the overall ratio. That is determined by the first and last gears in a simple (non-compounded) train such as this one used for the imperial threads.

Happy screwcutting. And I can highly recommend the Workshop Practice series book on Screwcutting in the Lathe as the easiest way to get your head around all this stuff.

Edited By Hopper on 10/07/2015 08:47:16

Edited By Hopper on 10/07/2015 08:49:07

Ian S C.