Hi Geoff,

Thanks for your interest.

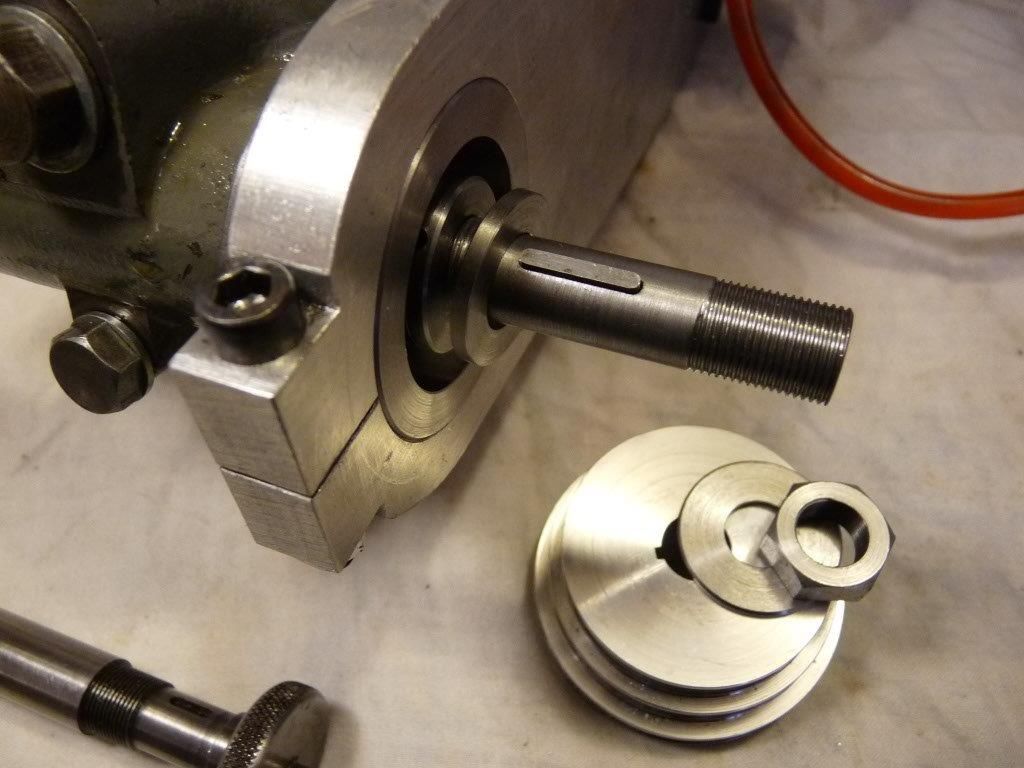

I thought it easier to dismantle and let some pictures do the talking.

This protrusion is in the way to use the boss on the rear of the spindle housing to hang the motor from.

Adding a close fitting, collar secured with a couple of grub screws, solved the problem. I used the original draw-bar collet spindle as a pattern, extending the pulley end and added an ER20 collet chuck at the business end.

The 2 existing end-float adjusting nuts now sit inside the new collar.

A thick washer spaces over the remaining thread and provides clearance for the pulley.

The motor mounting is a length of 4 * 1/2 inch alloy bar with a split clamp at the spindle end and air-fits to pretty it up a bit. This 1/4 hp small frame motor is secured at the business end; others may require a bit more thought. Finally, a couple of 3 step pulleys to suit the belt which is 6mm round-thane? or similar.

The motor can be rotated to a convenient position as required by each set-up.

When I got the Potts attachment it was just a well made ornament with a single 1/4 inch collet; now it has a new life.

Regards

Phil

CotswoldsPhil.