When stripping down and reassembling, due to bad memory, I've found it useful to:

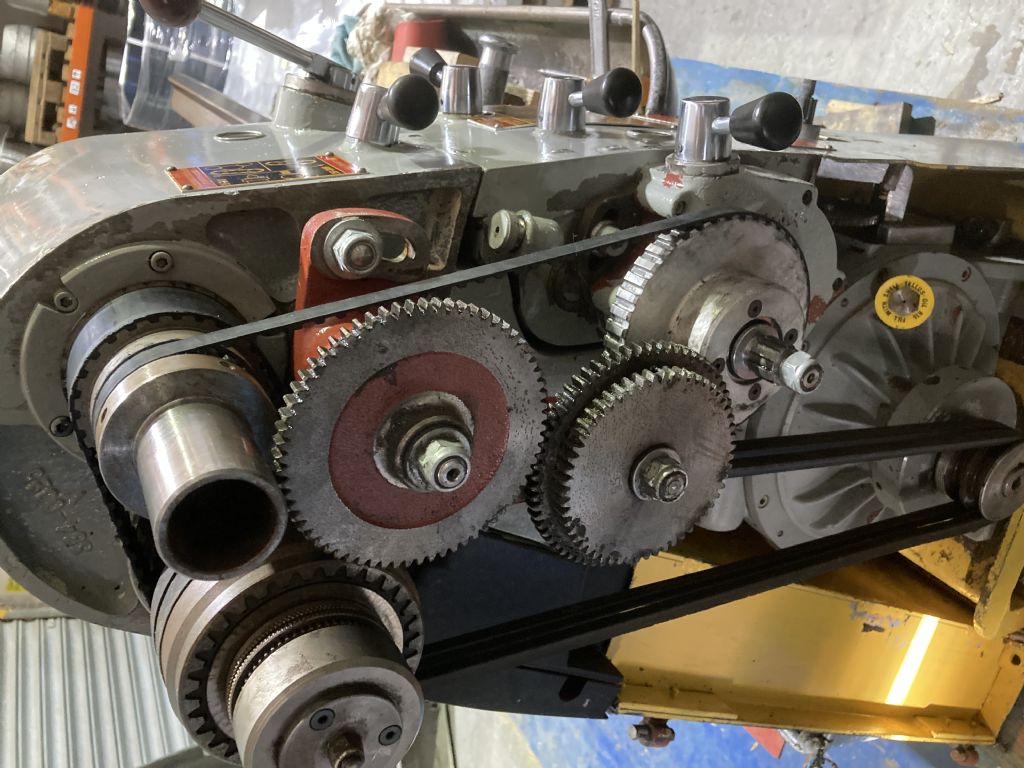

- Take many photos step by step as it comes apart. Then I can refer back to what it looked like before I got at it.

- Take notes. These record the order in which it came apart, which is important sometimes.

- Put related small parts like nuts, bolts, springs into small bags and label them!

- Try to keep parts assembled together, or taped in position so you don't have to remember.

- Don't take stuff off unless it's absolutely essential.

Booby traps. Don't ask how I know!

- Assembly that must be done in a particular order so you don't end up finding an untightened bolt behind the motor, which is hidden behind a cabinet, etc. etc.

- Items where it's unclear which way round it goes, and it turns out to matter!

- Small parts like washers, handle keys, terminal screws etc, dropping unnoticed to the floor.

- Not all washers are the same thickness. using the right one for correct spacing is sometimes important.

- Non-obvious grub screws, pins, or dowels locking parts in position so you break something getting it apart.

- Previous owner was a gorilla who tightened nuts up by hitting a spanner extender with a hammer.

- Watch out for minor details, for example gibs are often dimpled to accept the adjusting screws. They have to be put back the right way up, the right way round, and with the diimples aligned to their screws.

- Never lift with the spindle and don't lift heavy objects by their delicate protrusions. Although lathes are generally robust, it's easy to accidentally bend a lead-screw or break a shear pin. They don't like being dropped either.

- Wear steel toe-caps (near miss, thank god.)

- Over confidence.

- All the other booby traps I haven't fallen for yet…

Much more likely to go wrong the first time you do it. Once you know about details like gibs and dimples they're easy. But it can cause a lot of grief if you get small details wrong.

Don't panic. It's certainly all doable, but try to be organised. How difficult it is depends on the machine and how good you are at spotting problems: previous experience helps. Some machines are straightforward, others are a bit fussy. I need to take more care than others because I'm not a mechanical natural, but you might sail through it. Always good to share experiences like this with the forum. How you tackle it and what went well or badly will help others – please share!

Dave

Edited By SillyOldDuffer on 08/03/2021 08:27:57

jason evans.

, anchored low down on the machine and pull it up the slope, chocking on the downhill side every foot.

, anchored low down on the machine and pull it up the slope, chocking on the downhill side every foot.