Hi guys

I really appreciate your input.

Paul – yes it seems that your right about the limitations unfortunately. I at least expected to be able to machine flats on the end of a round bar or keyways, which would be best help in a locked lathe chuck.

The steel rule not a bad solution, which would probably be accurate enough in most cases. I do use that method for lathe cutters, until I can get a face cut.

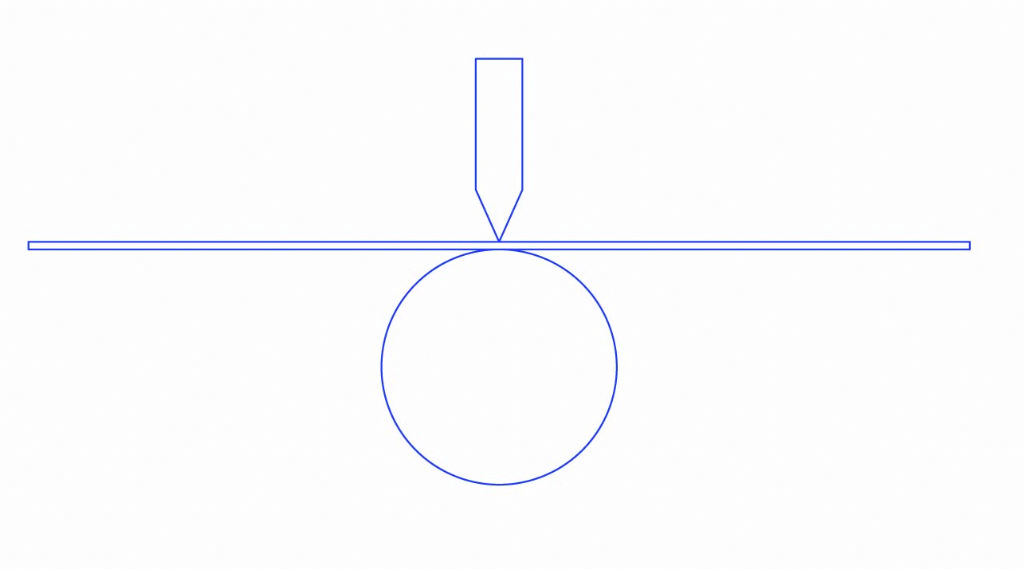

Martin, I assume you mean the image below. I think is probably the best and quickest method; notwithstanding the 4 days P&P. But Im sure the tool will be very handy in future. approx £10

NDIY – You mean marking the top of bar with the cutter. This is probably as accurate as the balancing ruler (only because its fully dependant on eyesight) and again would probably be good enough in most cases (e.g. drilling for a screw in a collar).

It looks like a very expensive self-centering vice is the best bet for this type of work if routine, and maybe some V-blocks in a normal vice is the most cost effective; but either way the centre finding is still necessary each time you set up from a lathe.

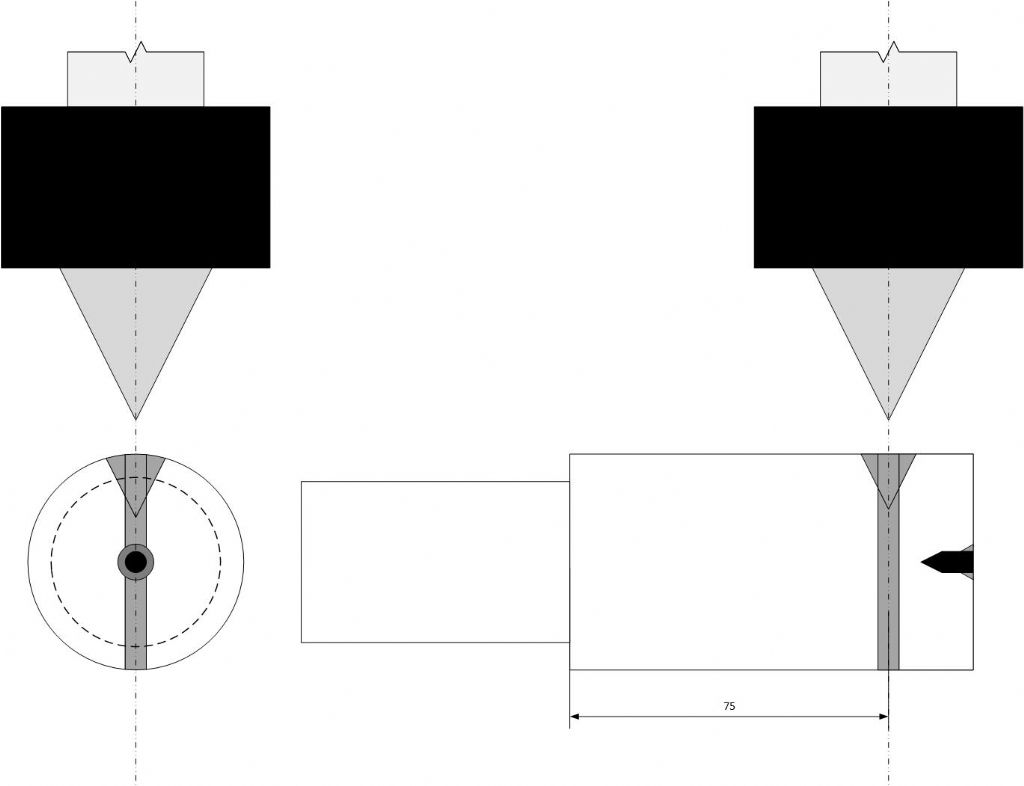

I did design a solution after I posted the querie last nigh. See below:

Its a piece of round bar with a centre hole and through-hole down the centre. You could then use either a centre or a drill/bar in the Mill chuck to centre up. Would still need Martins solution (round bar centre finder) to make this though.

The only constraint that I can see is the position of the centre-hole, which I think is approx 3" from my Jaws (hence the reason for spigot for holding in lathe chuck).

Of course this need to be perfectly at 90degrees, but a slight turning of both the chuck and mill head by hand would get this pretty bob on.

Thoughts, improvements, appreciated.

cheers

Danni Burns.