Ladies and Gentlemen, hello! First let me say thank you so much everyone, I've been reading this forum for a couple years now since I bought a myford super 7, and all the threads have been so invaluable. I can't thank everyone enough. With help from reading posts from this forum I've brought this beautiful old lathe back to life and have been getting some basic turning done.

But I'm stuck. my lathe came with 6 gears, 20,50,30,60,25,75.

Which all together can be used to form one ratio on the chart. 120 TPI. Not the most useful amount of teeth.

I think the previous owner was trying to get the carriage to move quickly, but just from experimenting with the gears if you just use 3 gears instead of 6 you can get the carriage to fly.

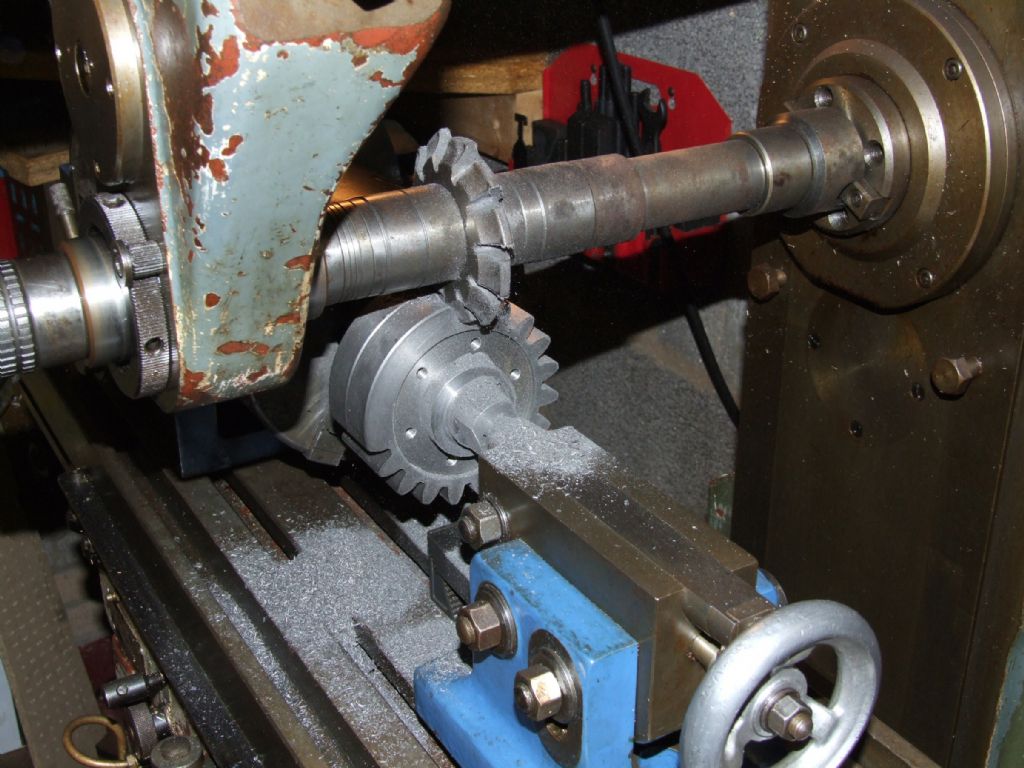

So what I need are to make 2×21, 70,40,45,65 and if I get ambitious the mythical 127 toothed gear. As well the large back gear has a tooth broken off, so I need to either fix that or make a new gear.

Now I know the number of teeth, and I know the inside bore (5/8) and I know the pressure angle 14.5 degrees.

But what I don't know is the nominal diameter that I need to turn the gear blanks too. I have a 3" bar of some sort of tool steel which i intend to use to make all the smaller gears with, so I'm set there.

I feel like this is so simple, and I've been watching tons of youtube video's and reading all the threads about gear cutting on this site and it's just not clicking in.

Would anyone mind taking the time to point me in the direction of somewhere that clearly explains how to get the diameter of the gear blank to make new gears that mesh in with existing gears?

Thanks so much everyone and hello from Canada

PS Another question, the dials on all the slides go to 100, which according to the myford website makes the lathe a metric lathe. It says the dials would only goto 40 if it was an imperial lathe. But when I put a clock on the back of the cross slide and move the hand wheel 5 graduations, the clock moves .005" which makes me think it's an imperial lathe. Does anyone know why this would be like this?

PPS some friends of mine have a pretty good quality CNC mill, and I feel like it should be pretty easy to machine new feed nuts out of titanium or something exotic like that, is there a way to get the exact dimensions of the feednuts from somewhere without resorting to amateur measuring, I don't trust myself to get accurate results trying to measure something like that part.

Thanks for any input you can give me, and thanks so much for making all your combined knowledge available to the young guys starting out!

Howard Lewis.