I think Hopper is right. I don't think a greasy belt would have such a dramatic effect; back gear drive is not connected, and Jason is most definitely correct on the weak grip on the job, but those points aside I had rather similar problems on my Sabel lathe, the Smart and Brown clone of the Southbend.

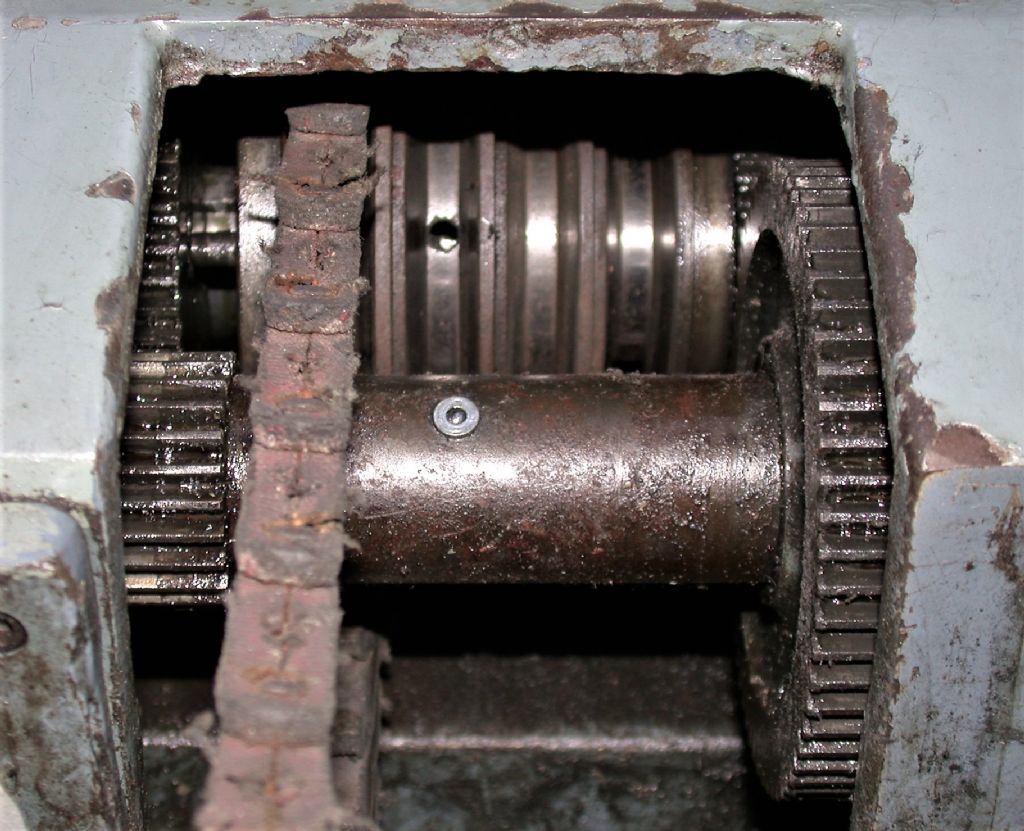

The 4 step pulley cluster on the Sabel countershaft is made in aluminium and over many years prior to my ownership the belt to the spindle had worn the pulley grooves in the aluminium to pronounced J shapes with the belt itself actually running on the bottom of the groove. I could easily bring a turning job at any speed to a halt with just the lightest cut and belt tensioning only made things worse. Once stopped in this way, light hand grip alone on the chuck was quite enough to prevent it from turning.

I was able to correct that by fitting a cast iron pulley cluster, only to find that the aluminium two step pulley on the motor was worn in exactly the same way, and had the same effects on cutting. I re-machined that pulley and swapped the belt for a slightly wider link belt type to compensate for the wider motor pulley grooves. These changes have transformed the lathe

In a past ownership the lathe lived in a woodworking workshop and I suspect the timber dust was the cause of the groove wear. The motor was full of such dust. It was not easy to spot either and only properly visible when compared to a corrected ground grooving tool

Brian

Edited By Brian Wood on 24/10/2018 10:25:28

Edited By Brian Wood on 24/10/2018 10:36:27

JP Santos.