Neil:

Thank you for considering this problem (I'm now assuming it was never answered in Scribe-a-Line). I am a retired accountant, not an engineer so I have a lot to learn.

I am also now in the process of machining a backplate, so this issue is front and center in my thinking (although so far I don't need to make an insert). The insert would be Plan B if the threading does not go as planned.

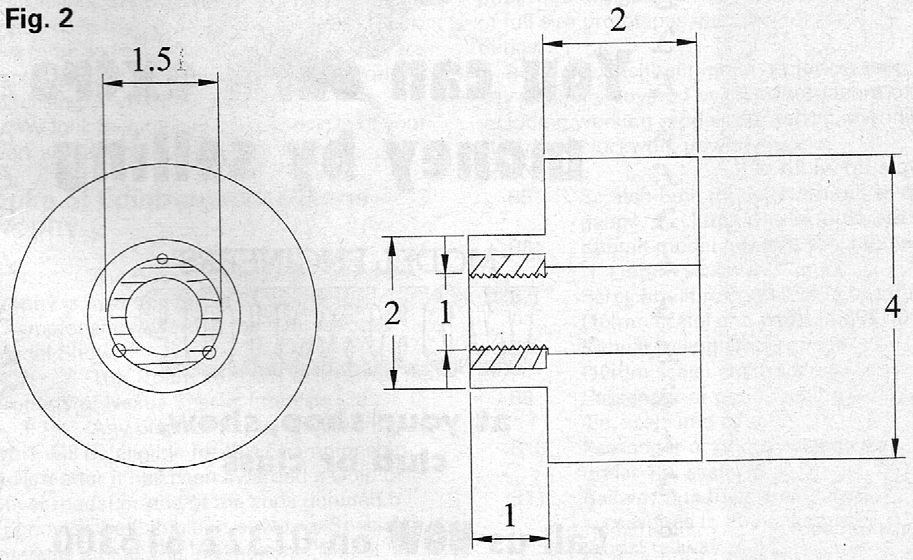

At Fig. 2, at the point where the inner right edge of the insert intersects with the backplate in the drawing, there is only 1/4" of metal (cast iron) in the (vertical) cross section. Is that considered a "shear or stress point"?

I was trying to compare it to a spigot. If this were a spigot, 2"OD and 1-1/2"ID made of cast iron, would there be a weakness at that same point that is overcome by the insert or by the fact that this is a tube? Tubal Cain and others suggest that cast iron is much better than steel for backplates, but cast iron is supposedly not as strong in tension as steel. The other concern raised by Ted Wales was to not press the insert it into the backplate due to the possibility of cracking the cast iron.

Paul

Paul Fallert.