Martin, I'll say it once again Read the rest of the thread.

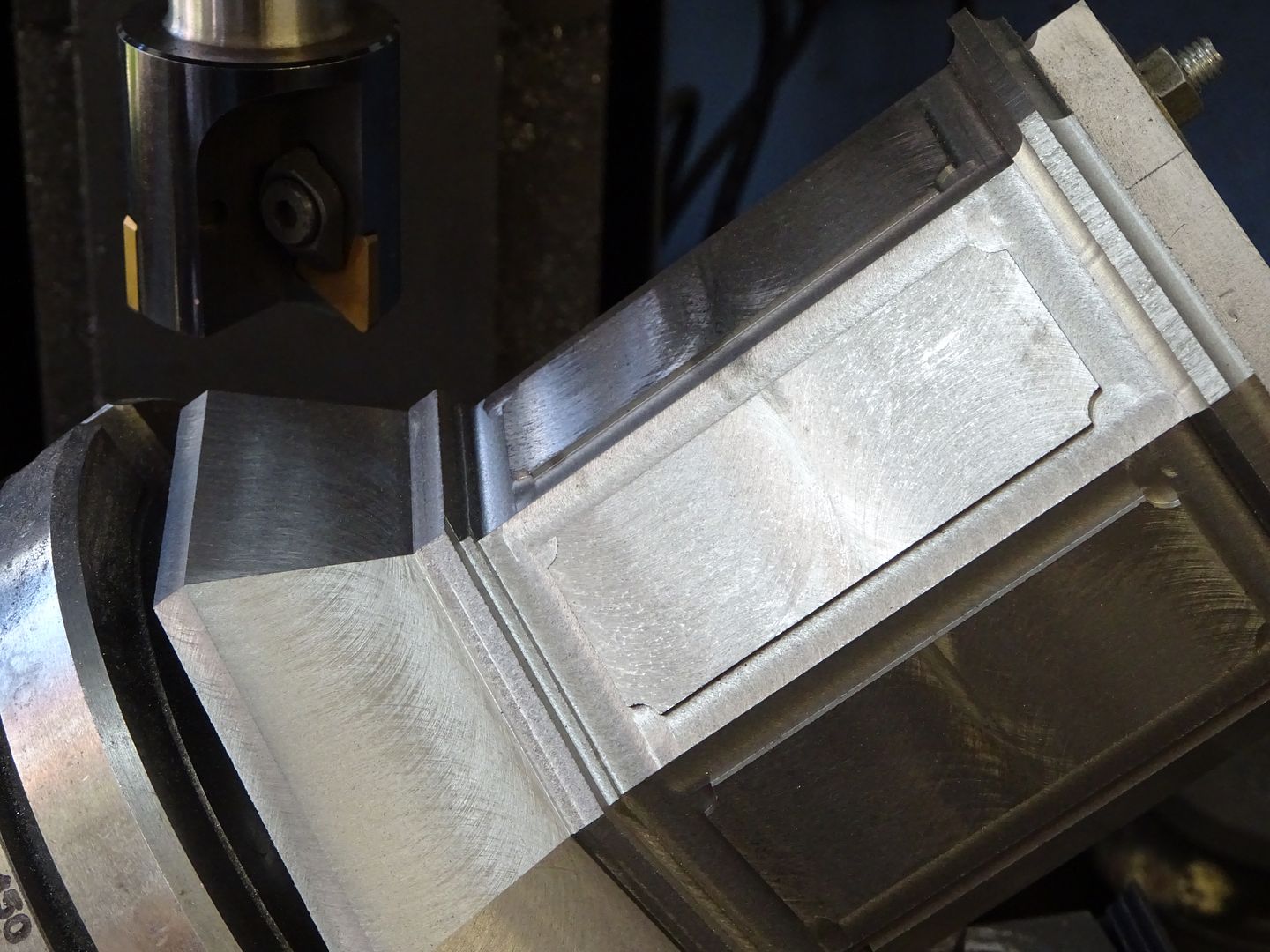

-I know what size cutter I'm using it was you that said it looked like a 1" cutter. 50mm cutter on 45mm wide work is not using the full width of the cutter.

-That is cast iron I'm cutting don't know of anyone who would suggest using cutting fluid on that.

-DRO has nothing to do with flex but does come in handy to eliminate the need for compensating for backlash.

Why not watch the other video I posted in the thread which you have obviously not done. CI first cut dry 45mm wide 1mm DOC, then steel with a little soluable oil 32mm wide 1mm DOC then aluminium with some paraffin 45mm wide 1mm DOC faster feed. All cutting well with no flexing as the tips were a better quality and geometry than the cheap Bangood ones.

Hardspots, yes one of the reasons I tend to use inserts on iron castings as you often find them on this material and it will blunt HSS as soon as they touch a hard spot.

You will notice that the chips from the steel are coming off blue, the suds really is not doing anything and may as well not have been used, this shows the tip is working right. Your loose wobbly chuck is most likely what is damaging inserts as well as pussy footing about with them.

Edited By JasonB on 14/05/2018 20:35:55

gary arthur.