Posted by Richard Cox on 06/05/2018 17:43:04:

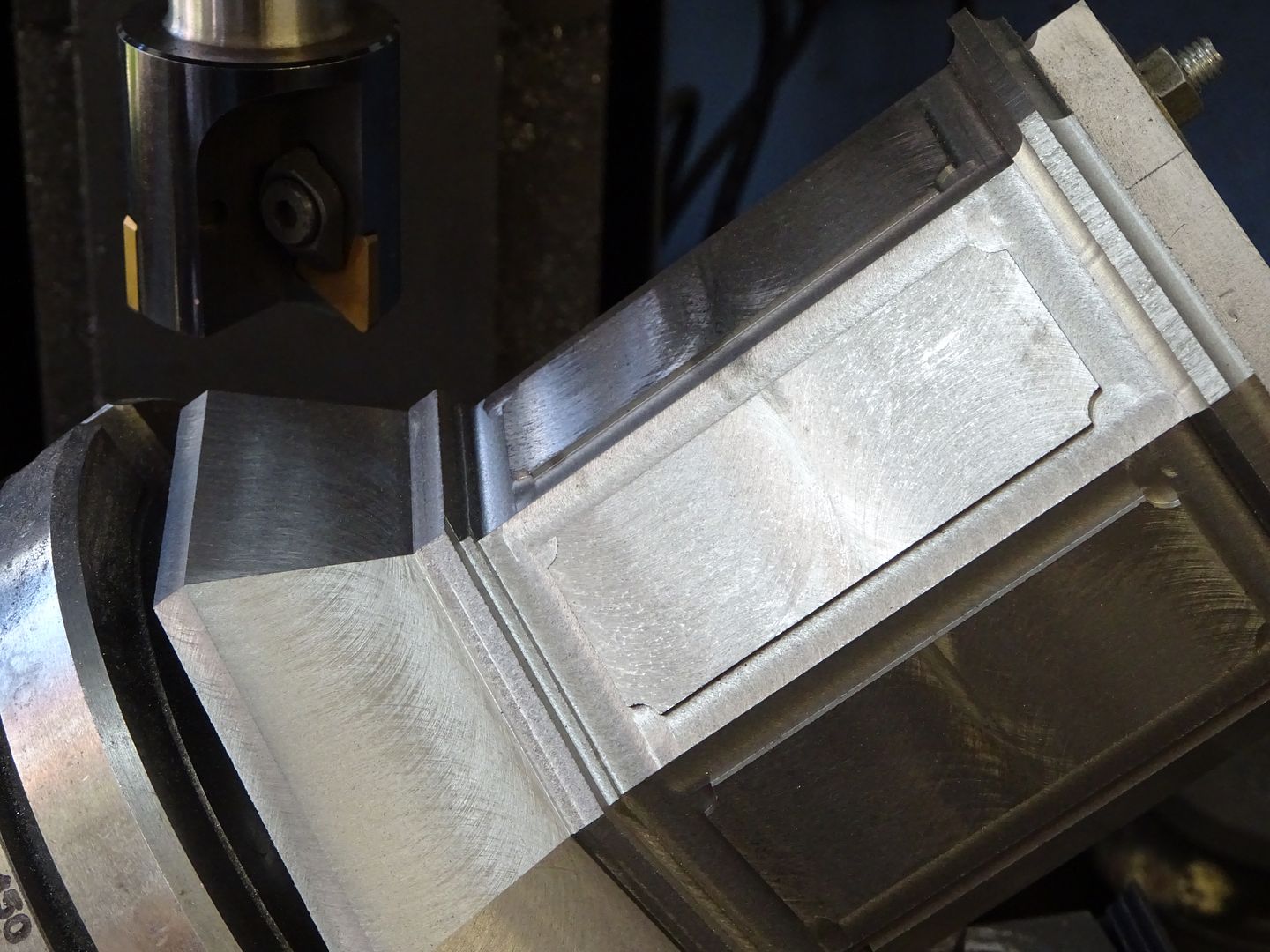

……also I have noticed when machining the head cuts twice eg tramming from right to left when the cutter that is not in the work passes over the cut edge it starts cutting again slightly,

Rich

That's what you'd hope to see. If the "back" of the cutter didn't make any kind of contact, it would suggest your head isn't trammed correctly and you will end up with a slightly concave surface.

It's not possible to conclude anything solid from the comments and video. Opinions perhaps but you'd need to do some more objective / methodical tests to narrow down what's happening. So for instance, to see if all the inserts are cutting, you'd need to examine them and possibly mark them to see if there is any contact. And measure the runout, particularly the axial runout etc with a decent indicator. I think that's one thing John Doubleboost missed out on.

The speeds and feeds are important for these indexable tools. It's not clear if there were any calculations done or if the handles were just being turned. Even without CNC, it's got to be a good idea to set your power feed to the right speed range recommended by the insert manufacturers.

Murray

For reference, for mild steel I would be using 1000rpm and 0.1mm / tooth ie about 500mm / min for a 5 insert cutter. Good idea to use coolant or WD40 even.

Edited By Muzzer on 06/05/2018 20:32:38

gary arthur.