Posted by Hopper on 27/10/2018 01:13:48:

What on earth is a "submarine snail shell chariot"? And what is it used for? A fish tank decoration or deep sea defence ordnance? Even google does not reveal this one.

I'm not surprised Google is is silent on this – the project is a bit hush-hush, national security and all that. However, I have clearance to reveal this much:

It's called the Nautilus for obvious reasons, and will probably change the face of of naval warfare.

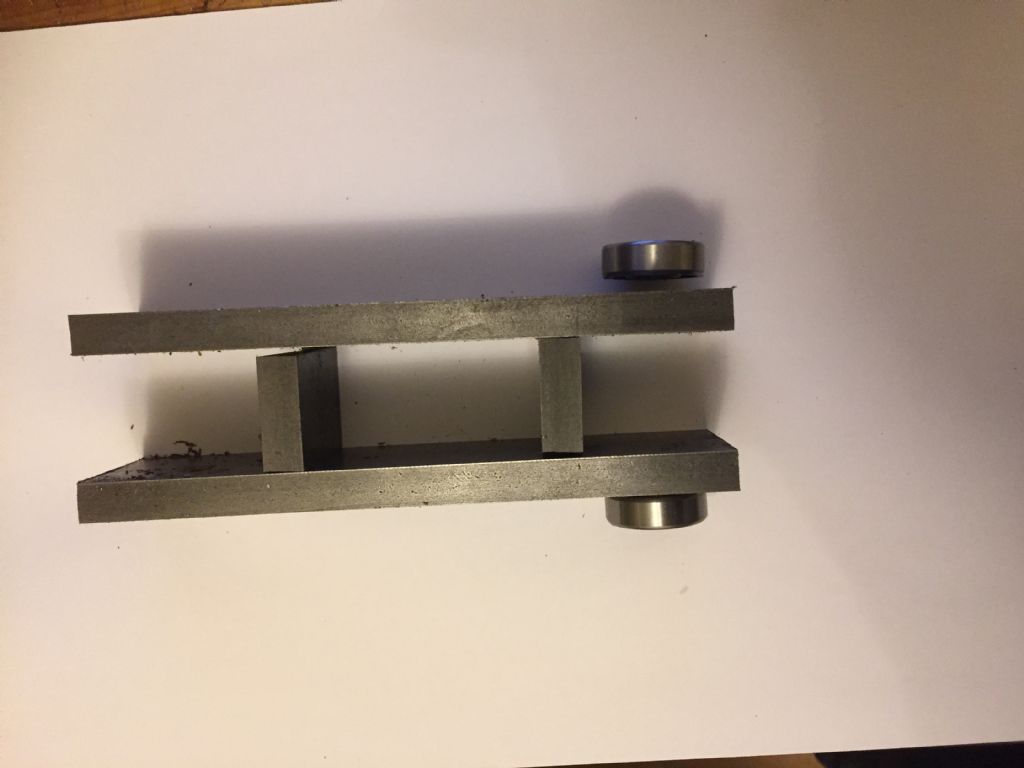

This was one of those embarrassing questions where the solution becomes obvious after sleeping on it. I can do what I want by making up the frame then drilling/boring on the faceplate – I just forget that I have that resource because I rarely work with awkwardly shaped parts. Learning (slowly) though!

Thanks for suggestions of alternative ways of fixing the bits together. Truth to tell my decision to weld was to do with having bought a welder for another project and being so pleased with my new toy that I want to weld everything at every opportunity. I'll get over it I expect.

Robin.

Edited By Robin Graham on 29/10/2018 23:12:37

Robin Graham.