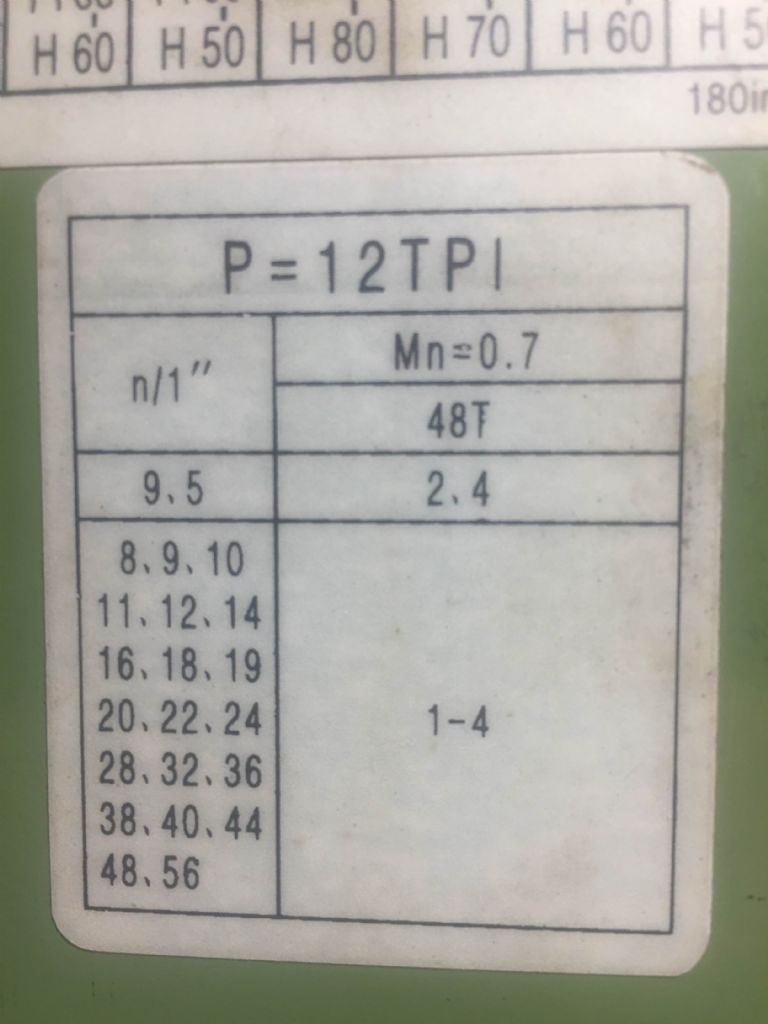

This label seems to be saying that you have a 12 thread per inch lead screw. The threading dial gear that engages with it is module 0.7 with 48 teeth. This gear has a pitch circle diameter of 0.7 x 48 giving 33.6mm.

12 tpi into 48 gives 4 so I believe the threading dial will rotate once every 4" of carriage travel or 1/4 of a turn per inch of travel. If the dial is divided into 4 then each mark will show 1" of travel. This means that for any thread with a whole number of threads per inch you can engage the half nuts at any mark on the dial. For threads with 9.5 or 11.5 tpi you need to travel 2" to get to the place where you can engage the half nuts. That requires the thread dial turning 180 degrees so you should engage at opposite marks such as 1 and 3 or 2 and 4. The makers have picked the even numbers but could just as easily picked the odd numbers.

Martin C

https://www.model-engineer.co.uk/albums/member_album.asp?a=46824

Link above is to my album on understanding the threading dial.

Edited By Martin Connelly on 22/10/2018 19:25:07

Geoffrey Fairhurst.