A lack of fillet radii – cannot be over stressed.

Okay, I am playing with words here but in the light of the above remark …

The radius is more theory than practice …

and with due respect to Hopper (assuming we are referring to thread root and not thread crest), in the many years while I was ‘doing’ technical service, the vast number of moulded products that failed in service, failed through lack of adequate fillet radiusing. This included a wide variety of threaded components, e.g. caps, closures, water filter canisters, and on through a wide assortment of moulded parts, big and small.

The source of the problem was often tool design or mould-making oversight, i.e. sharp edges left on the external corners of mould cores and profiles.

For further reading – Google ‘Fillet radii’ and a myriad of examples will appear.

My apologies if I’ve covered this somewhere else.

Regards,

Sam

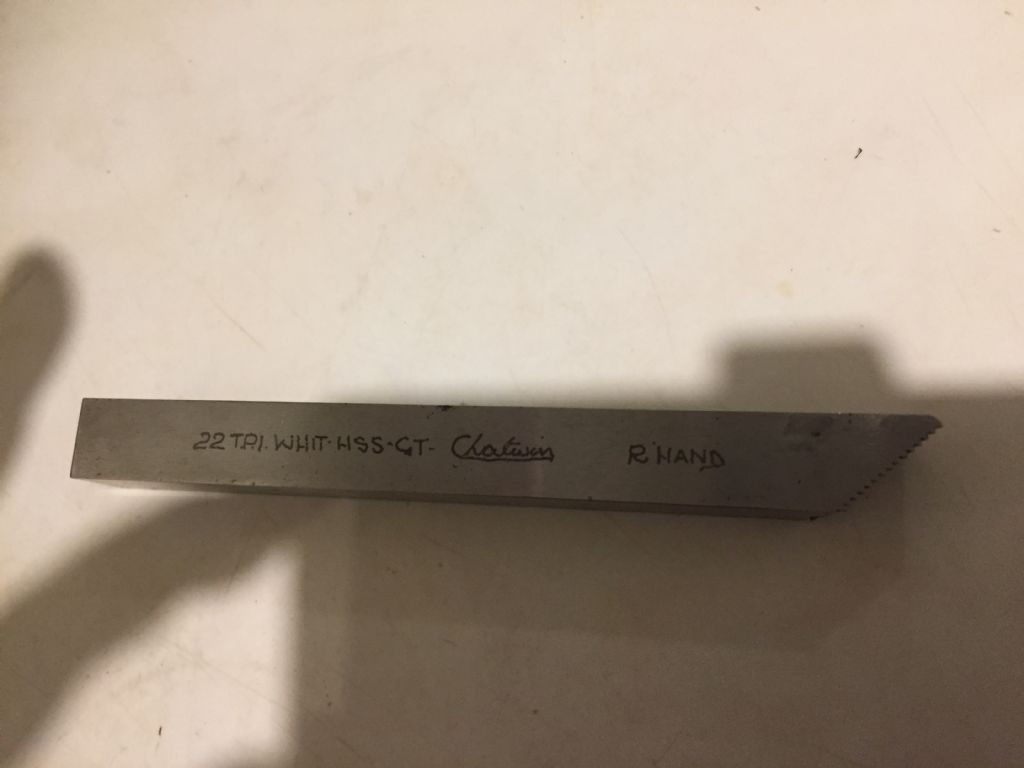

BTW – when I bought my (now long gone) ML7, it came with a box of thread chasers, mostly with tangs for hand chasing.

That's a fascinating video of pen making, especially the method of closing the lathe collet.

Edited By Sam Stones on 20/10/2018 00:19:38

ega.