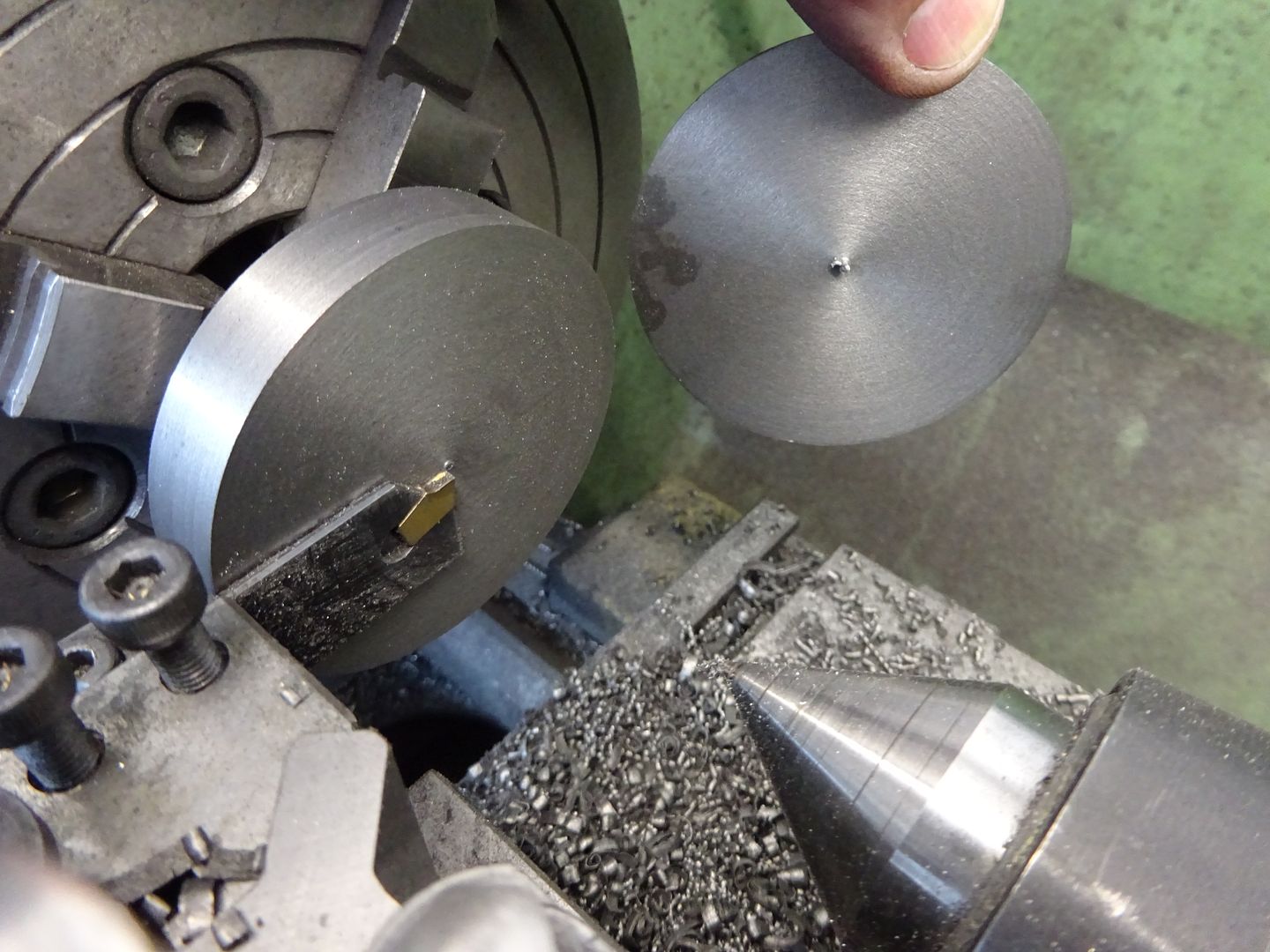

I work on a Sieg SC3, use a HSS-Co8 parting blade clamped in a home made holder that clamps the blade in the side face. The blade has no top rake, only ground on the front. HSS-Co8 is much tougher than a straight HSS blade, the ones I use are I assume Chinesium but they work. When I first had the lathe I had a carbide insert holder, but gave up on it after having to use a HSS blade when the supplier was shut.

Saddle is clamped to the bed, after positioning. Compund slide is tightened but not fully clamped, the reason for this is so I can make a wider cut than the single blade width. I do this so that the swarf clears the side of the blade, I take a plunge cut, then move slightly to the side to take a second as I move the blade in. Cutting speed is around 400RPM, dependant on diameter, adjust to suit diameter as you feel confident. Don't overhang the compound slide from the cross slide as this will allow movement on a small machine. I have cut unto 75mm diameter in steel, it took time but it did cut. Use a cutting oil to keep the tip cool, I use a spray cutting fluid from Toolstation. Most of my work is with steel, softer metals like brass and phosphor bronze are less of an issue.

thaiguzzi.