Good to see that people are building live-steam locos from scratch in these smaller scales.

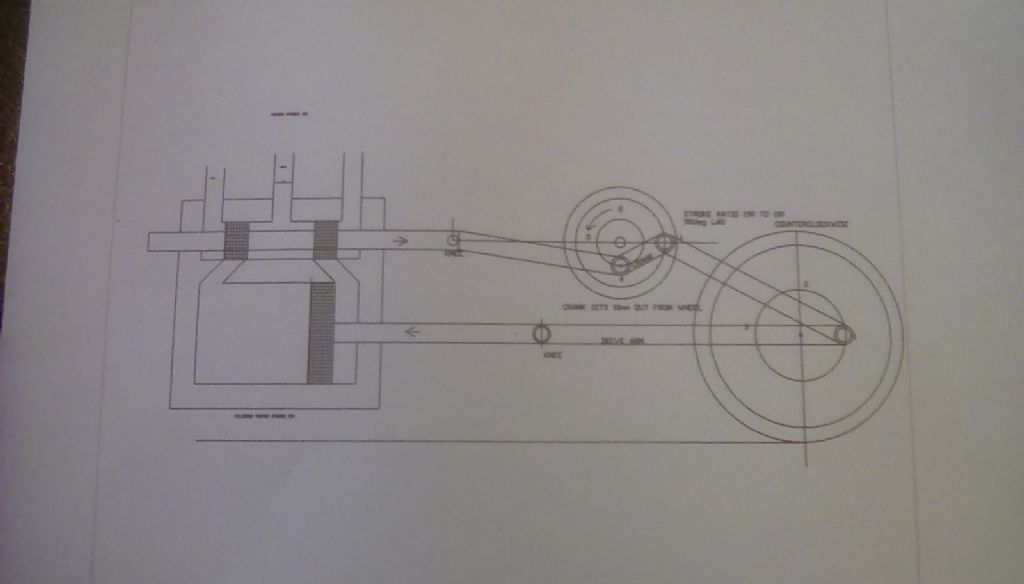

To be honest though, unless you intend the engine to run only ever forwards, any gear more elaborate than a slip-eccentric will need about as many separate parts as any other; but is not straightforward to design..

As Redsetter points out, an oscillating cylinder is not the answer it may seem, and also needs a fair of work to disguise the fact if outside the frames – though some owners of commercially-built oscillator models have done that successfully.

My own society has quite a number of members who own Gauge 0 and 45mm -gauge locos, admittedly mostly commercially built, and the club facilities include a raised track for them. Although I am not such an owner I have noticed that none of their engines normally needs a helping hand to start, but they are all two-cylinder machines and seem to be double-acting, many with a simplified Walschaert's Gear radio-operated along with the regulator. (I don't think they can be notched-up, nor need it.)

So I am a bit puzzled by Norman Dewhurst's observation, and whilst I'm sure he was a good craftsman and his point about crank-axles is fair, I suggest his engines need the Maradonna touch because they rely on a single cylinder – not vice-versa!

.

Nigel Graham 2.