Guy's,

Apologies for any spelling mistake in advance Im dyslexic so please make allowances!

I bought a 1954 J&S 540 with the plain bearing spindle about 12 months back. Gave it a quick once over and used it to grind in the mag chuck and rough grind a tool makers vice.

As I had some heavier machining to do not he vice I decided to fix the leaking spindle oil seal and clean out the spindle oil. Replacement oil seal arrived a week or so ago along with some fresh oil. So today I though I would get it all back together. New oil seal is a R21 1.3/4 X 1 X 3/8.

So this morning I started assembling. Press in the new seal into the holder add a thin layer or sealant and refit to the head. Add oil. No leaks.

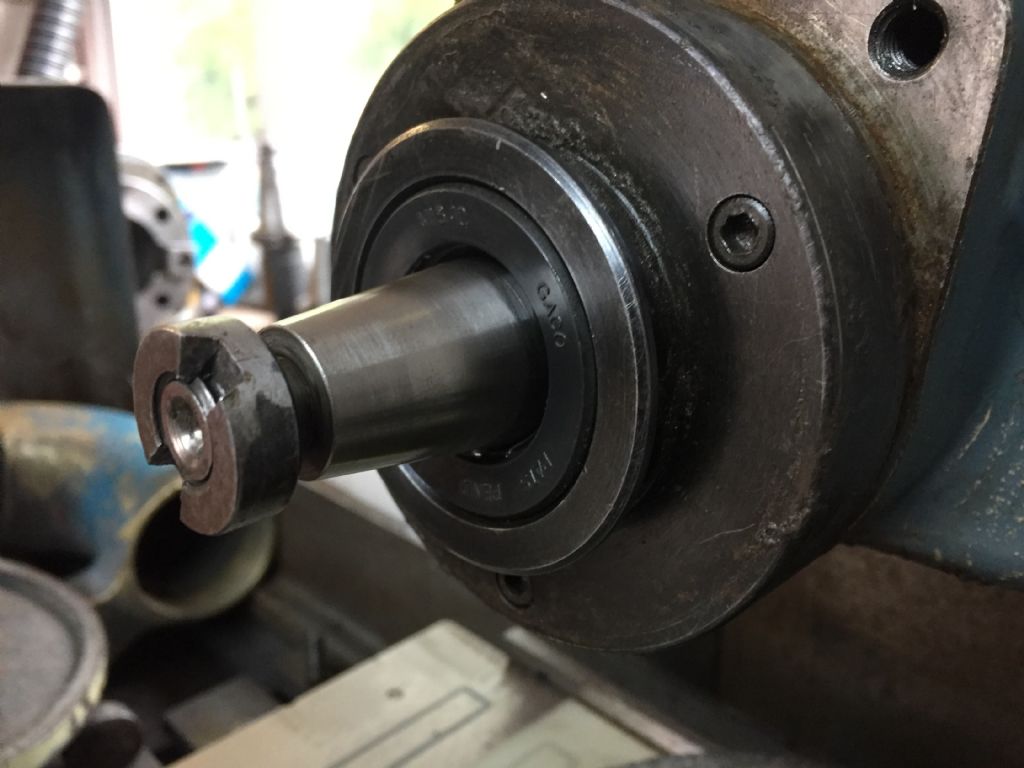

Then I try refitting an arbour without a wheel just to check it all fits. This is where the craziness started.

I pushed the arbour onto the taper spindle and it fealt terribly loose fit. So I put the nut on and wound it finger tight. Still wasn't happy, something fealt wrong. As I removed the arbour I could see its had deformed the oil seal so bad it has started leaking.

Have added some pics can anybody see anything off? The oil seal sits flush with the plate that holds it, but the little raised boss on the back of the arbour is pressing into it.

Its almost as if the spindle it not sticking out of the machine far enough, or I have the wrong arbour of the oil seal is too thick. What confusing me most is I used to for hours before I replace the old seal so it cant have been that bad as it did a reasonable job give its age.

Thanks,

Ian.

Dave S.