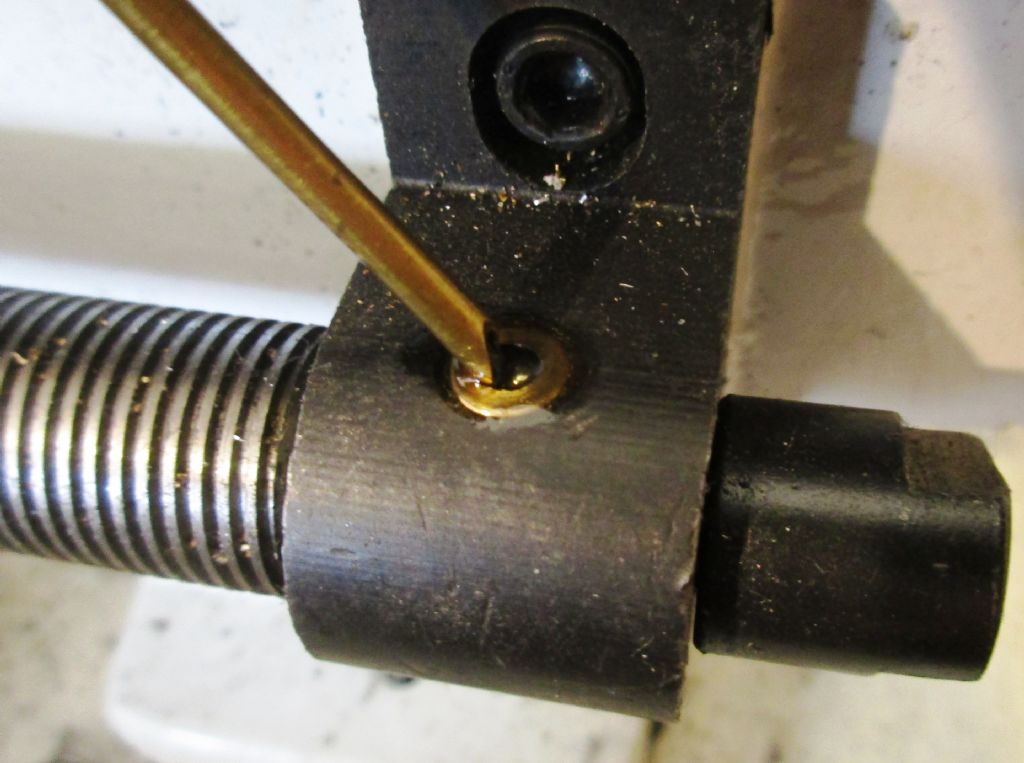

Not familiar with this model, but the second question is easy. That type of oiling point is very common; inside a spring holds a ball-bearing in the hole to stop muck getting in. Any oil-pump with a nozzle that fits well enough to move the ball when pressure is applied will do. It's easier if the nozzle bends, though I just use the ordinary type and put up with a bit of mess and having to keep the pump full. The ball can also be depressed with a nail if only a gravity can is available.

I'm guessing, but the big screw in the first picture looks very much like a bulk oil point for the gears. Undo and have a look inside: if it's just a cover and gears can be seen, that's what it is.

The hexagon sight gauge might double as drain plug. Sounds like a splash system in which just enough oil is added to wet the lower teeth of the biggest gear, which soaks the others as it spins. In which case the head doesn't have much oil in it and is only topped up when the level drops. Could be daily if the lathe is used a lot, probably less often in practice. It's a lossy system, so there may not be a separate drain. Oh, and don't overfill a lossy system because excess oil goes everywhere!

Lathes of this type aren't fussy about oil. H32 or 20W should be fine.

Dave

Edited By SillyOldDuffer on 11/12/2022 16:55:24

Hopper.