Hi all,

This is my first post as I have managed to find the answers I need to most things on the forum. However, I am now stuck!

I have inherited a Warco BH600 lathe which is in fairly good condition. Except for one thing. It will not start! The green light comes on but nothing else happens at all.

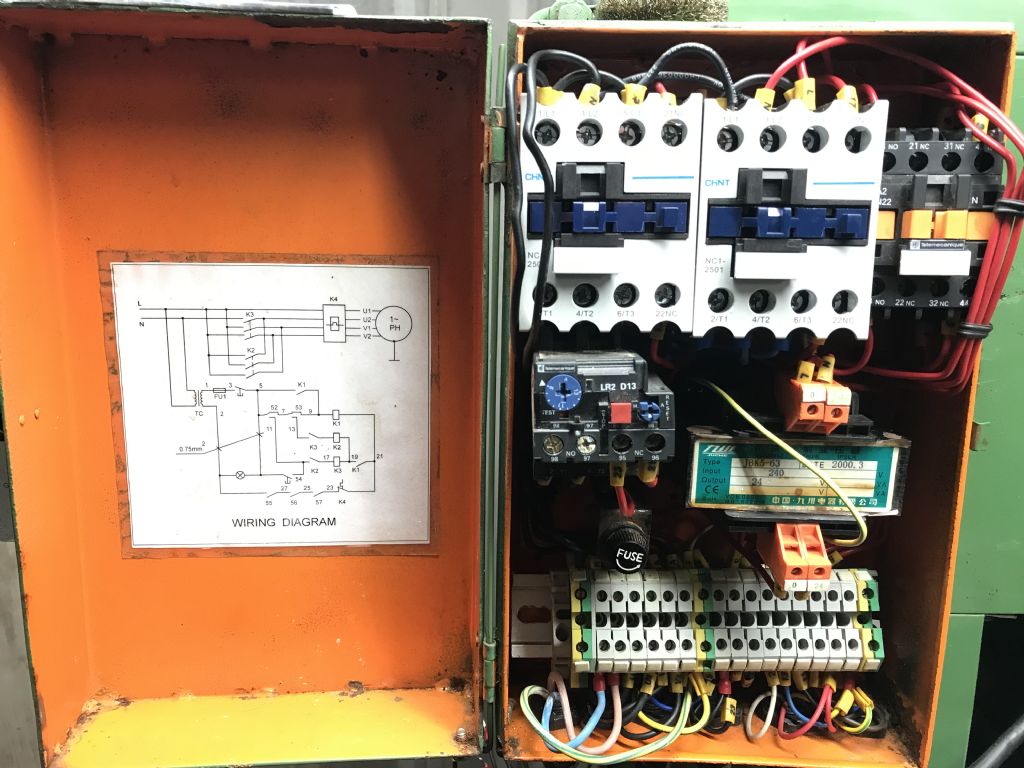

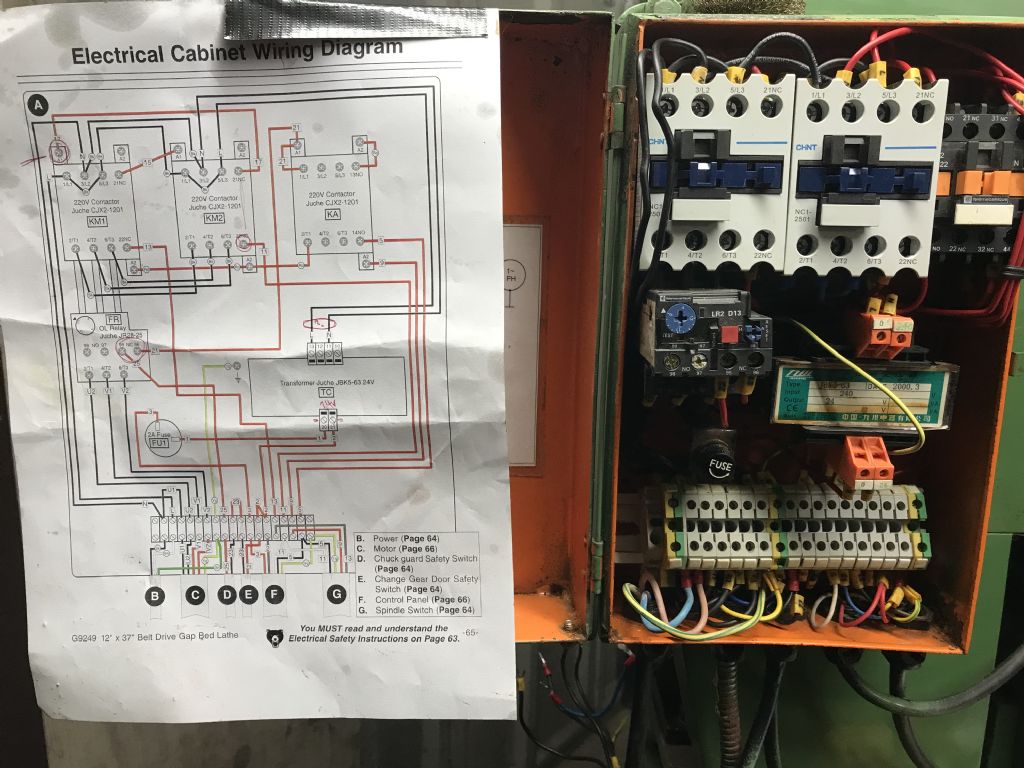

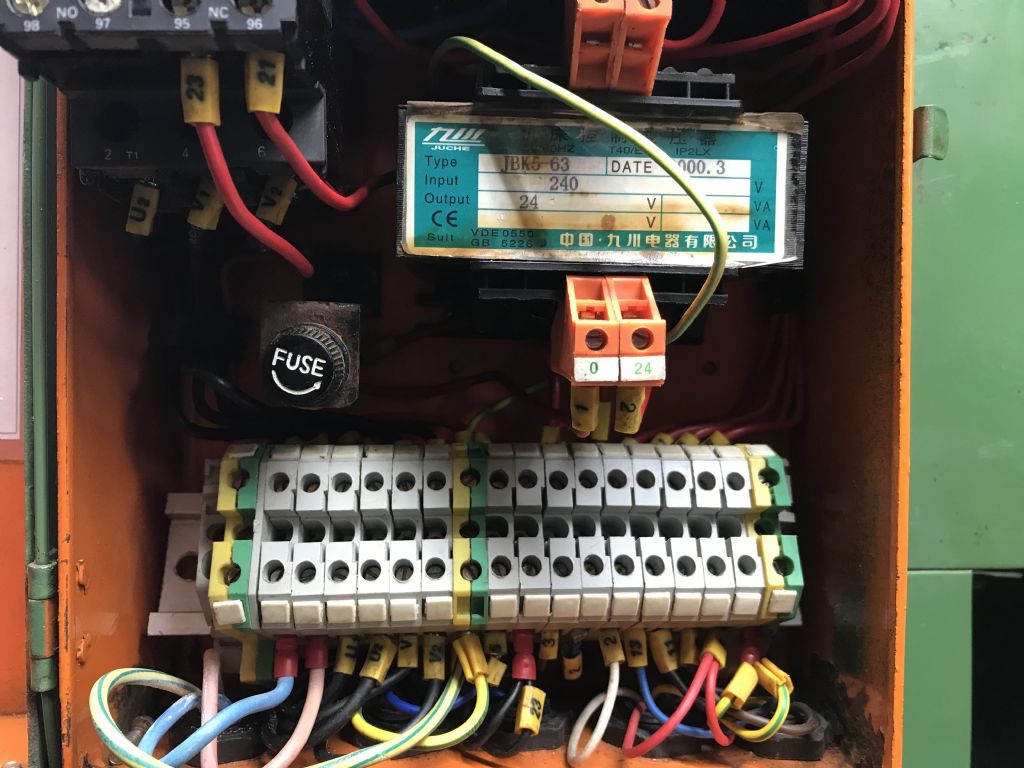

So far I have checked the following – plug fuse, machine fuse, chuck guard safety switch, change gear and top cover safety switch, start switch, emergency cut off switch, security of all connections, continuity of all wires, continuity and discontinuity of contactors, contactor coil resistance, transformer output (24v) and wiring diagram as per Grizzly 9249. The Warco wiring diagram is not to helpful.

I have now spent nearly 2 days trying to figure it out. The motor will run forwards or backwards depending which contactor I press. However, when I turn the machine on the contactors do not react and nothing happens when pressing the start button.

If anyone has any sensible suggestions as to what else to try they would be very welcome. I have looked at it so many times I think I have memorised the wiring diagram!

Thanks in advance.

Joe Snowden.