I bought a part rebuilt Union Tool cutter /Grinder from a well known auction site. With the need to be able to sharpen Endmills, Slotdrills MT drills, and hoping to be able to do a little surface grinding; there was a 10" x 5" mag chuck with it  Typical Photos here http://www.lathes.co.uk/uniontool%26cuttergrinder/

Typical Photos here http://www.lathes.co.uk/uniontool%26cuttergrinder/

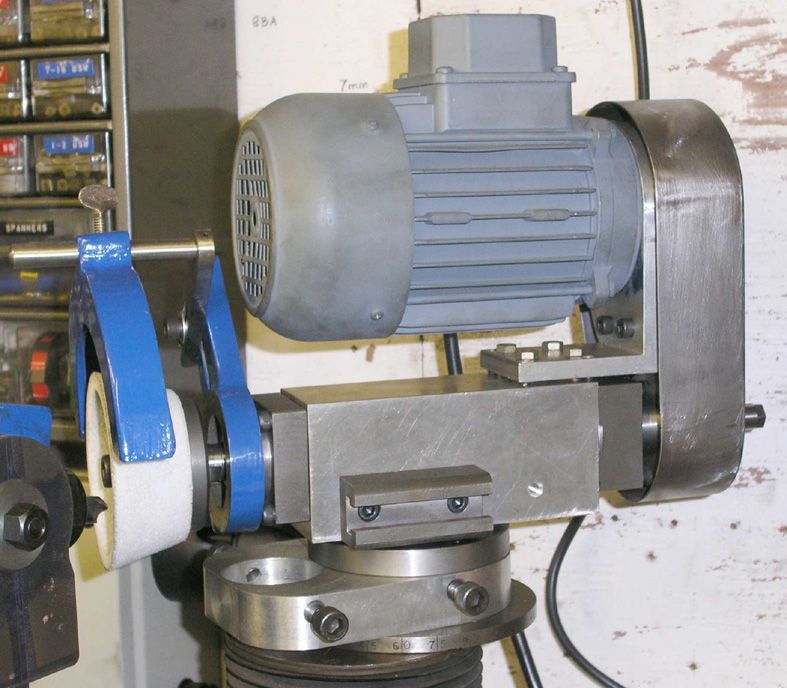

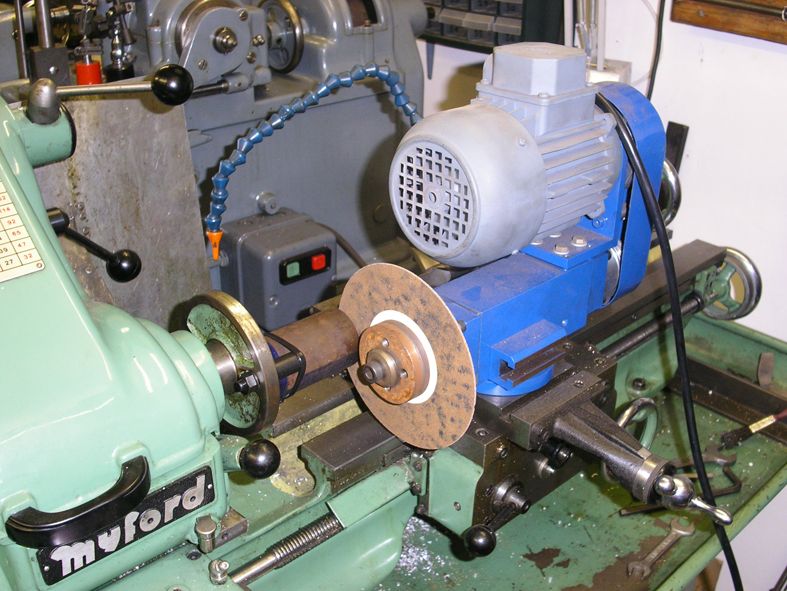

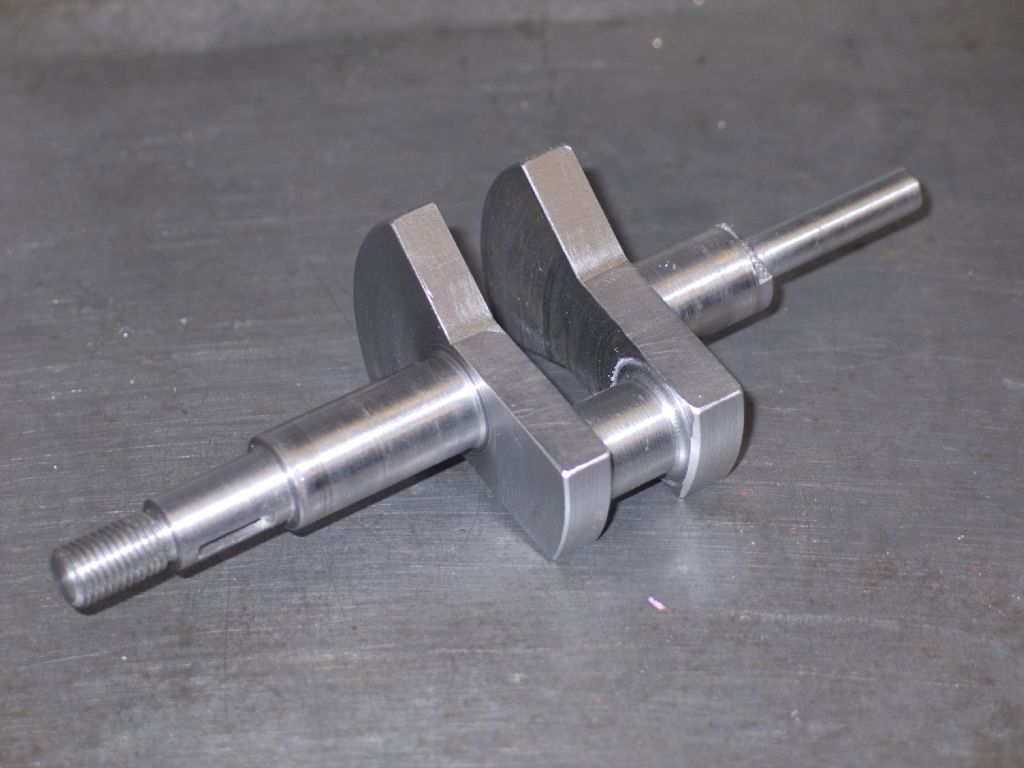

Built a new universal head, that takes R8 collets, and managed to make usable a tupperware of 1/4" – 3/4" cutters; finish was not so great on the bigger cutters so investigated the motor (3 Phase squirrel cage)… All I had previously done was to shim it horizontal to the work table.

The bearings are single row ball races, on a bent shaft that used to be 5/8, but now .005 – .007 less than that and sort of ellipical. There were no seals on the shaft other than the endcaps (now also oversize and oval). End float was removed using two wavy shim washer…All of this was full of congealed oil and grinding dust; very effective grinding paste – It's stuffed.

I've seen the wonders than John Stevenson can perform, but it will cost me as much for the bearings, seals, and a heap of time to have a working 40 year old motor.

Any good reason why I don't buy an off the shelf foot mounted motor, with dust seals and make a new mounting plate? It would also mean that the ability to rotate the motor wouldn't need bent spanners, a torch and skinned knuckles (the bolts are inside the motor mount!).The Worden uses such a motor.

Single Phase would also save the use of my inverter for the lathe and mill,it's only need 375Watts and the original was single speed.

I am sure this forum will now tell me what I'm failing to see  Thanks in advance!

Thanks in advance!

p.s. I know I would not be restoring it to it's former glory, but it might standa chance of being more useful!

Eric Storey.

Typical Photos here

Typical Photos here