Speed required depends on the work: material, diameter etc. For most practical purposes on smaller work I leave the lathe at a 2:1 step down on the drive from the motor countershaft (approx. 2:1 pulley diameter ratio) so around 700rpm usung a 1400rpm motor.

I have the option also of the middle step on the pully giving me a 1:1 ratio roughly, so 1400rpm – this is as fast as i would ever go on this lathe but rarely used. Also a step up using the smallest pulley – I don't use this.

The motor and its countershaft both have 2/3/4" 3-step pulleys so I can double or halve the speed here also – I almost invariably use the 3" sections on both so the countershaft runs at the motor speed. The previous owner had made the motor drive arrangement this way and I have had no reason to change it.

So using the step down 2:1 to the motor countershaft I get around 350rpm. I think using the back gear gives me around a 6:1 step down so maybe down to 60rpm (I am not in a postion to check it at the moment) for larger work / higher torque.

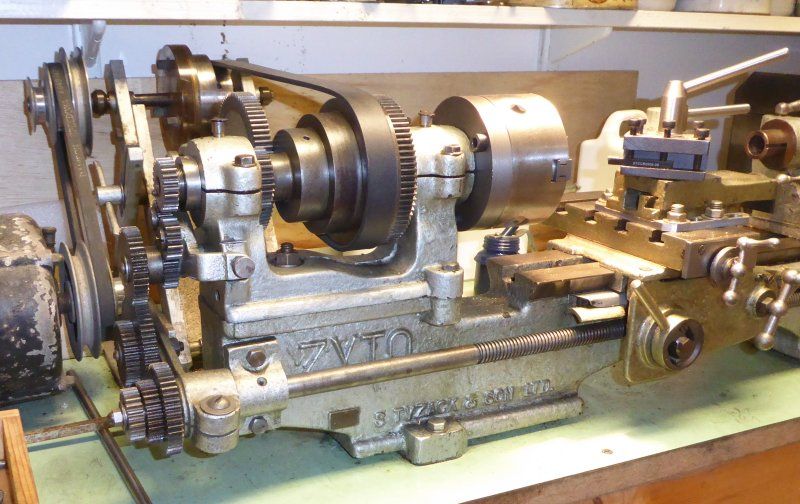

The spring-loaded pin: the pulley is largely hollow with a couple of webs – there is a hole drilled in one of the webs for the pin to go into, to engage direct drive when the back gear is not used. So the pin can be pulled out and rotated 90 degrees to alternately put it in the locked or unlocked settings – the cross-pin being then either on the surface of the pulley side, or dropped into the recess. A previous owner had at one time managed to break out the web hole side and repair it by using a small steel block screwed inside the rim of the pulley having a hole drilled in it to take the pin. I did a little fettling of the pin at one point making it slightly longer with a stronger spring because it was liable to jump out of the hole on the pulley at times.

In regard to the oil disappearing from the oil cups rapidly, which I think you mentioned elsewhere: don't worry about it. Mine does this, especially so on one of them; just give it a drink occasionally. But it still works fine; it is not so large and rigid as my Warco WM250, but the runout using the 3-jaw chuck is better than the WM250 at around 1 thou vs. 3 thou. The Zyto still has a valued place in my workshop.

Martin

Edited for spelling!

Edited By Martin Whittle on 29/12/2018 09:09:51

Cician Cratimaru.