Hi there, Richard,

The main spindle has a spline groove down most of its length, it might be two grooves, diametrically disposed, I can't remember. Then, inside the stepped pulley there's a rather odd-shaped bobbin sort of 'gizmo' that fits round the spindle – this has male spline(s) in its bore that engage with the spindle groove(s) to provide the sliding drive. This 'gizmo' is (on my Tauco) made of zinc-based die-casting alloy. When I got mine, the male splines had worn paper-thin and hadn't much life left.

After lots of research (no Internet in early 1970s) I found that Wilkinsons in Edinburgh had Tauco spares and supplied me with a replacement 'gizmo'. I did Google Wilkinsons a year or so ago and they were then still in business; I don't know if they still have any stock of Tauco spares.

Unless the 'gizmo' in your machine has healthy splines, I fear it is junk, unless you can procure a replacement or home-brew some substitute. So I suggest your first priority should be to strip off the stepped pulley and eye-ball what that reveals!

I believe that the Tauco drills came over to the UK from the USA during 1939-1945 WW2 as Marshall Aid or Lend-Lease. Mine has given very satisfactory service and one or two other members on this forum have them.

I made my own control box containing a MEMDOL single phase direct on-line starter and a forward-off-reverse switch; the box is bracketed off the motor mounting plate. I expect the starter in your photo is similarly mounted.

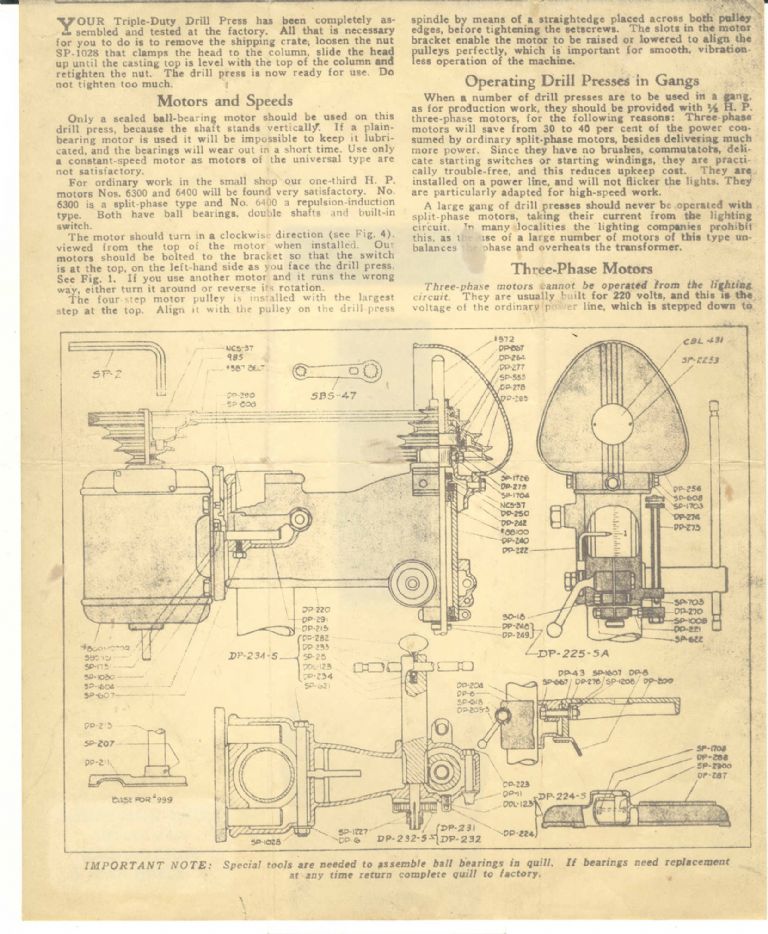

If you PM me with your email address, I may be able to find a .pdf of the illustrated parts list (aka 'exploded diagram' ).

Best regards,

Swarf, Mostly.

Mark Learmonth.

saved this Tauco drill from the scrap man. Are they any good ? Worth restoring ?

saved this Tauco drill from the scrap man. Are they any good ? Worth restoring ?