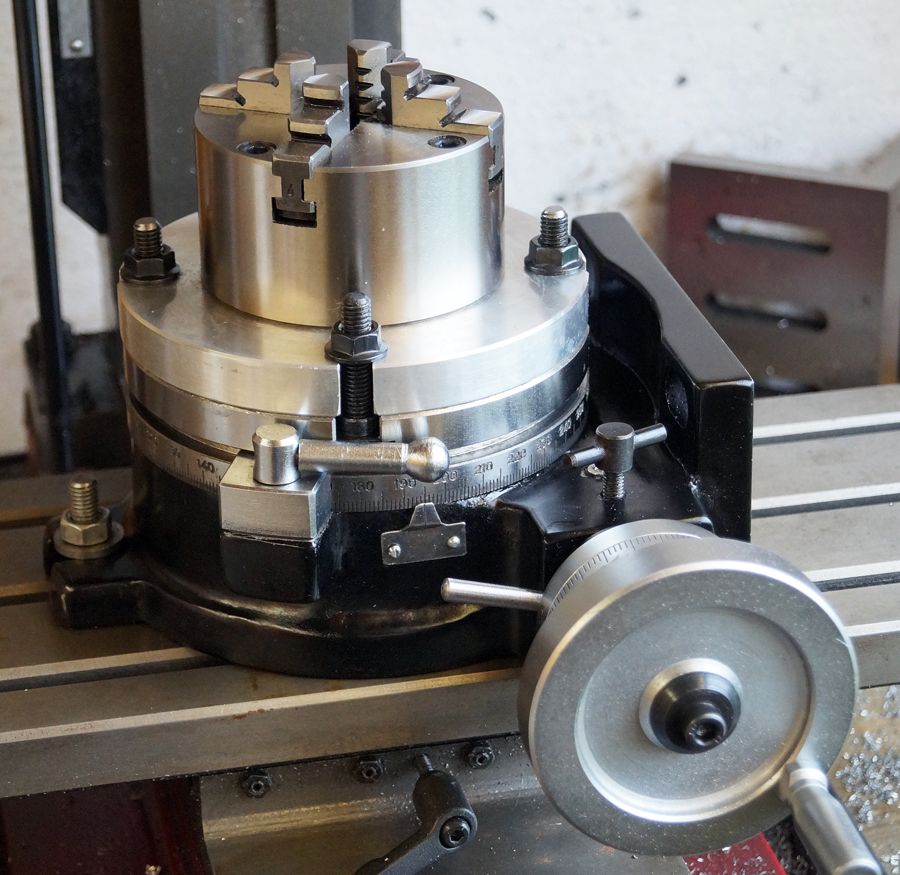

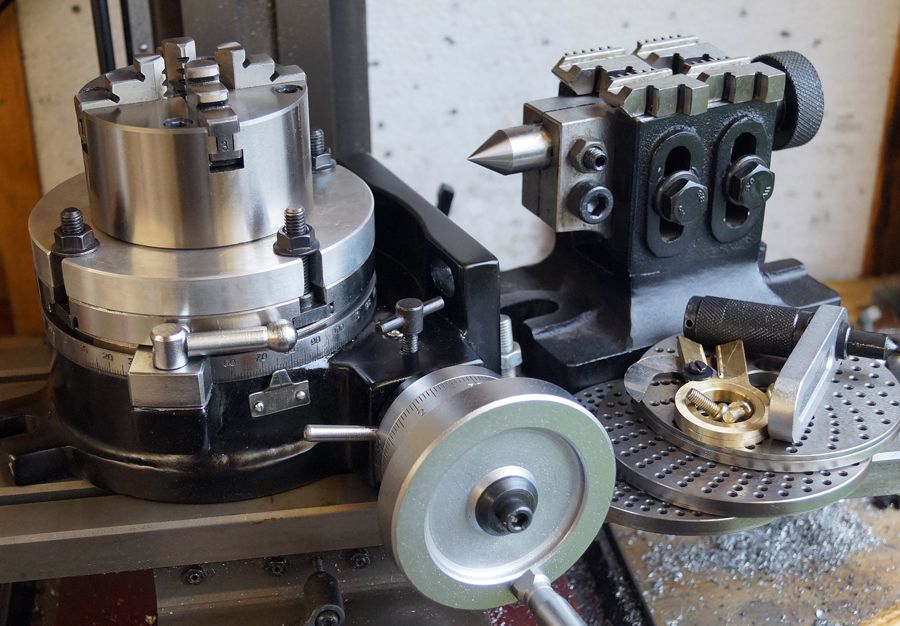

The 5 inch Soba arrived so I gave it a check over whilst bearing in mind what Neil found on the 6 inch version.

Turning the table through 360 the handle felt very smooth with no tight spots though it did feel a bit light so I adjusted the gear mesh which is simple to do via a grub screw. Adjusted to get a bit more feel on the handle but with no tight spots, checked the backlash at that setting which is 0.001" so I am hardly going to worry about that.

I clocked the outside of the table through 360 and that is good to 0.0002", so running as near as damn it true. I then tried to find any float across the table using the mounted chuck for leverage but couldnt find any movement at all, the gauge maintained zero.

One turn of the handle is 4 degrees, I checked it at a number of settings and it is spot on.

So going by these checks I am obviously really pleased I couldnt ask for much better.

Down side..? there always has to be a downside, the 80mm 4 jaw is self centering not an independent but I,m sure it will have its uses. Also the chuck key with the 4 jaw needs a few thou of the key faces as it hardly enters the chuck.

Sakura.