We have two threads, running concurrently, on really the same subject – the inability of the OP to part off successfully.

I really think it is time for the OP to step back and consider every aspect of his working practice and improve each and every one to its maximum.

Among others, we have, so far:

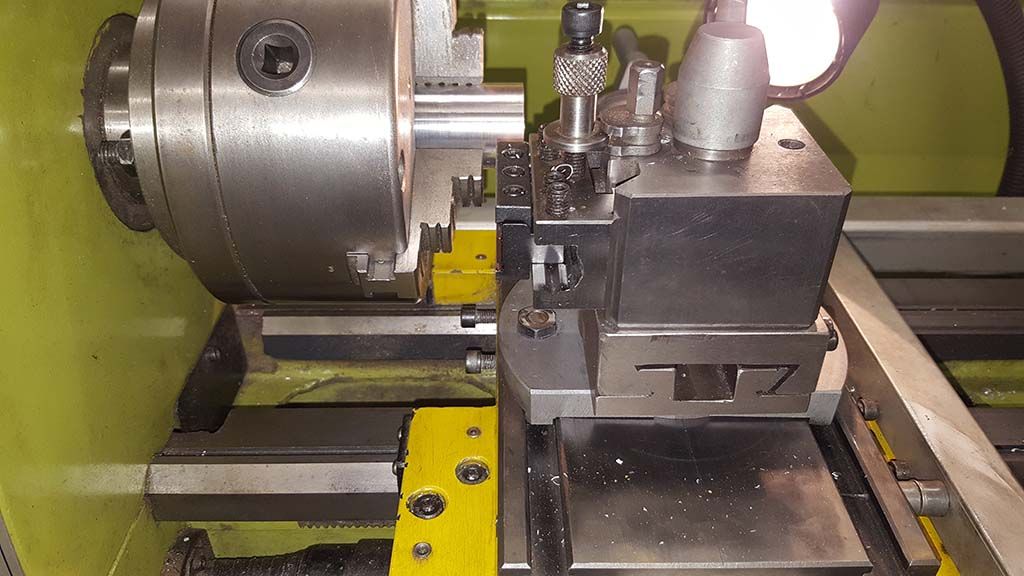

Possible excessive overhang from the chuck with no additional support.

Possible excessive overhang of the tool from the holder.

Possible excessive overhang of the tool from the carriage.

Non locked-down axes while cutting on another.

Possible drawbacks with the machine design.

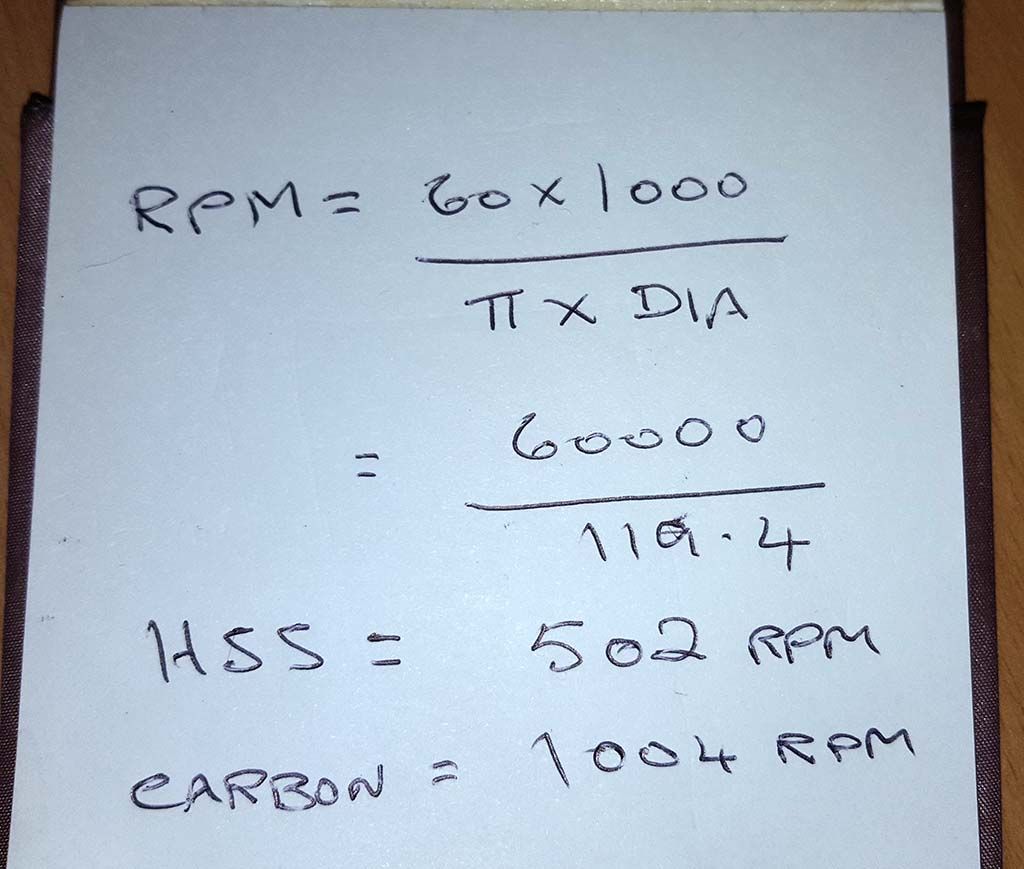

Cutting speeds in relation to diameter of work, material and cutter type.

Apparent differences between tool holders and some examples not being secured properly.

A possibly compromised parting-off tool.

Possibly poorly secured, or loose, tool post on the top slide

Likely others, too, not listed above from this or the other thread but that little lot should provide at least some considerable practical improvement in this task.

We don’t actually know which (or combination) of these factors led to the original cry for help. So time, now, for all the possibilities to be examined by the OP? Then, and only then, the OP might try parting off again, because changing one thing (in this case) seems very unlikely to solve the problem in one go!

thaiguzzi.