Ketil (and Nick),

If you have access to another lathe do the following:

Get a tube of micrometer blue (or other engineer's blue)

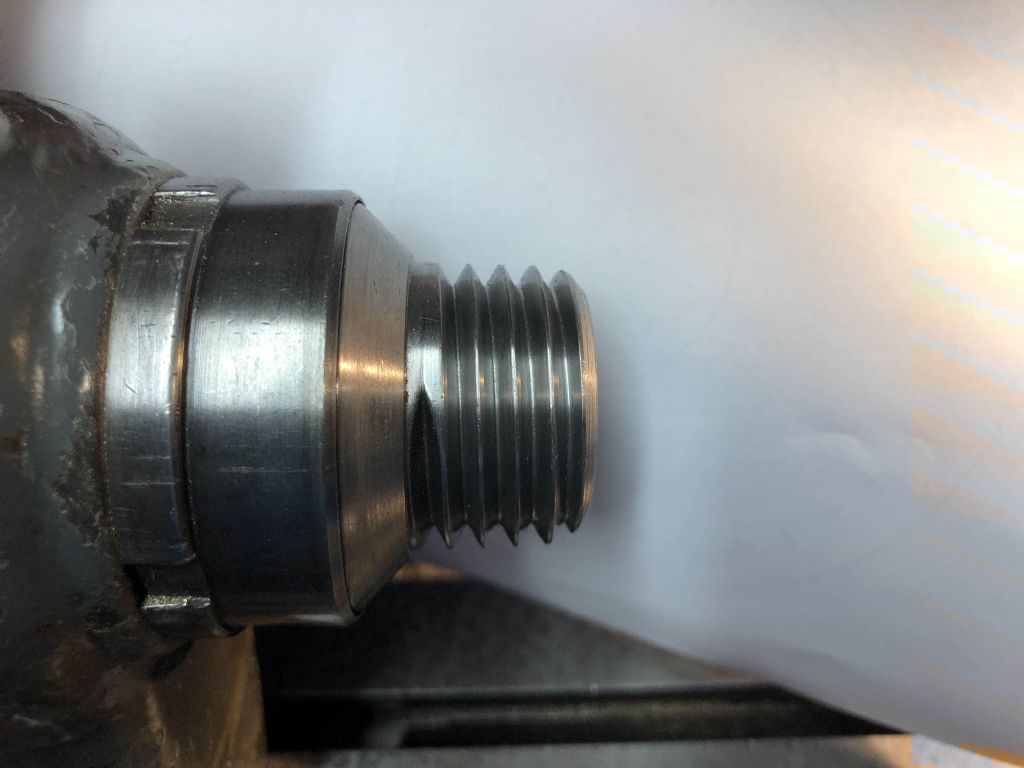

Bore a piece of stock so that it will pass over the thread and the OD register. This is a test-piece to get the taper angle set on your compound.

Make a template from card or take measurements to get the approximate angle of the taper from the threaded part. Use it to set the compound angle on the lathe.

Now cut the taper in the piece you bored.

Blue up the taper you cut and use it to take a print off the taper by pressing it lightly and giving a bit of a turn. Removing and replacing the test piece in a 3-jaw will not affect your results at this oint and there's no need to dial it in, just re-cut the taper each time.

Adjust the compound angle until you get a good print on the spindle from the piece you cut and then keep the compound set to that angle. Keep that tool in the toolholder so the tool height is preserved because adjusting the height even slightly will change the angle.

Now get your backplate blank, face, bore and thread it for the spindle all in one setup then cut the taper on it. Everything will now be concentric and you can finish off facing and turning the OD with it mounted in the Mikron. that will ensure the best mounting face for your chuck.

Edited By Pete Rimmer on 30/10/2018 13:44:31

Pete Rimmer.