The only real answer to making by ordinary turning methods a crankshaft too flexible to be self supporting lies in making a suitable support jig .

At simplest the jig need only consist of an arrangement of clamping plate to stiifen all the throws not currently being worked on and leaving only one journal unsupported .

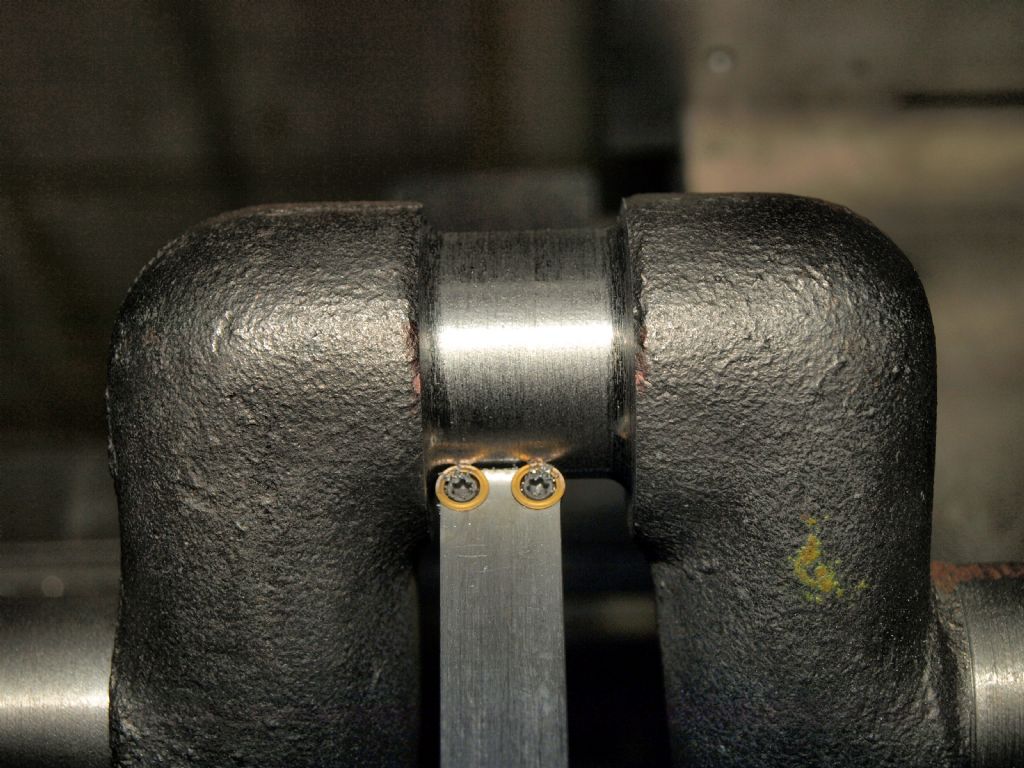

Far better though is to make a proper wrap around jig with a hole in it and removable support pins and clamp screws such that all of the headstock end of the crankshaft is enveloped in the jig and just the currently being machined journal is sticking out (plus any previously machined journals of course but these don’t matter ).

There are two versions of the wrap around jig :

One with an axial hole which is set true for al the main journals and then reset eccentric for all the throw journals .

One which is in two parts with an eccentric main hole and then a sleeve with an eccentric hole to take the crankshaft . By setting the inner sleeve and the crankshaft itself in different ways the crankshaft can be set up to run true on the main journals or true on the throw journals but the main body of the jig does not have to be reset .

There are advantages in using round bar to make crankshaft with these jigs but round bar is by no means essential .

There is actually a third variant of the wrap around jig which is useful where there is only one throw – the bore in the jig body is itself made eccentric such that turning the crankshaft blank around in the eccentric hole sets either main or throw journals to run true .

MW

JOHN BRIDGE 1.