Update on my Kennedy resurrection – from a very unskilled operator.

Here is what I have achieved and learned so far with all the generous advice from you all….

The lever to keep the boom elevated was simple and quick to make with 6mm and 8mm mild steel rod, articulated with a small bolt, an 8mm compression spring and a handle. Works perfectly.

The machine switches itself off now using a flat piece of alloy which presses against the switch when the boom is fully lowered. This was a simple design but quite tricky to get right. It’s not perfect and I would not leave the saw completely unattended.

The saw did not cut straight – I tried a 1” and 1.5” width blade which did the trick but could not source one with any more teeth than 14tpi and this kept getting stuck as it was too aggressive. 18tpi is definitely the sweet spot for my machine even with pulley belt dressing to make it stickier. I changed the belt from lathes.co.uk which did not solve the slippage problem and cost £28. The off centre cuts stopped when I rebuilt the dash pot and put a 96mm x 8mm tension spring between the dashpot arm and a 6mm bolt whose tapped hole I found on the main casing. I bought the spring from eBay for £3.96.

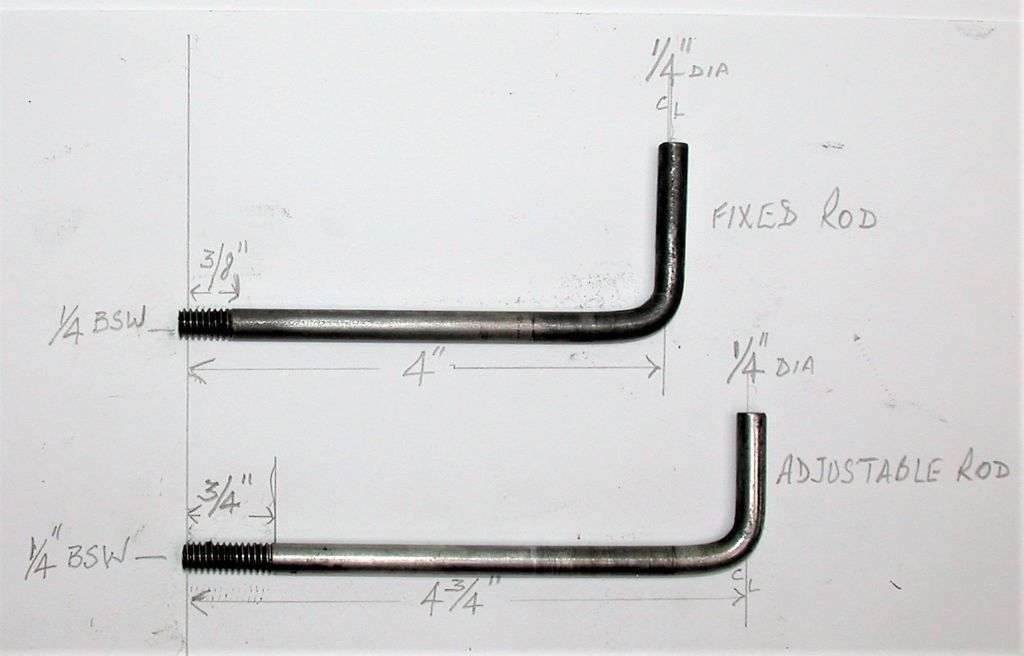

The dash pot bellows was equally simple but took me a few goes as I do not have a metal lathe. I butt welded 2 sections of 25mm flat mild steel and then cut out a 20mm depth disc using a 40mm diameter HSS hole cutter. This made the diameter 37mm which was just right to slide up and down the pot cylinder. It was easy to drill out 3 x 8mm and 3 x 6mm holes which provides the route for the oil to flow. I found that all 8mm holes and there was too little resistance. I found any bigger disc and the plunger caught. There is much scope to improve this if I aligned the rods better but it works. I made the bottom washer from 0.8mm alloy in a similar way. The two rods were made from 8mm mild steel with a length before bend of 4 and 4.5 inches respectively. I used SAE 90 gear box oil and found, thanks to a mate of mine, that the a Clio steering rack boot acts as a perfectly sized rubber cover. I had to fill the pot pretty full for the dampner to work from top to bottom of the cut.

My last job is to construct the depth gauge stop so any pointers most appreciated.

I am also looking for a 45 degree vice that Kennedy made as an optional extra if anyone knows where to source

Thanks once again – such an enjoyable project.

Jez

Jez Hunter.