Rather than clutter up other threads I thought I'd start a separate thread on the theory and practice of helical gears. At least that way those who have no interest will not be bored by unexpected minutiae in other threads.

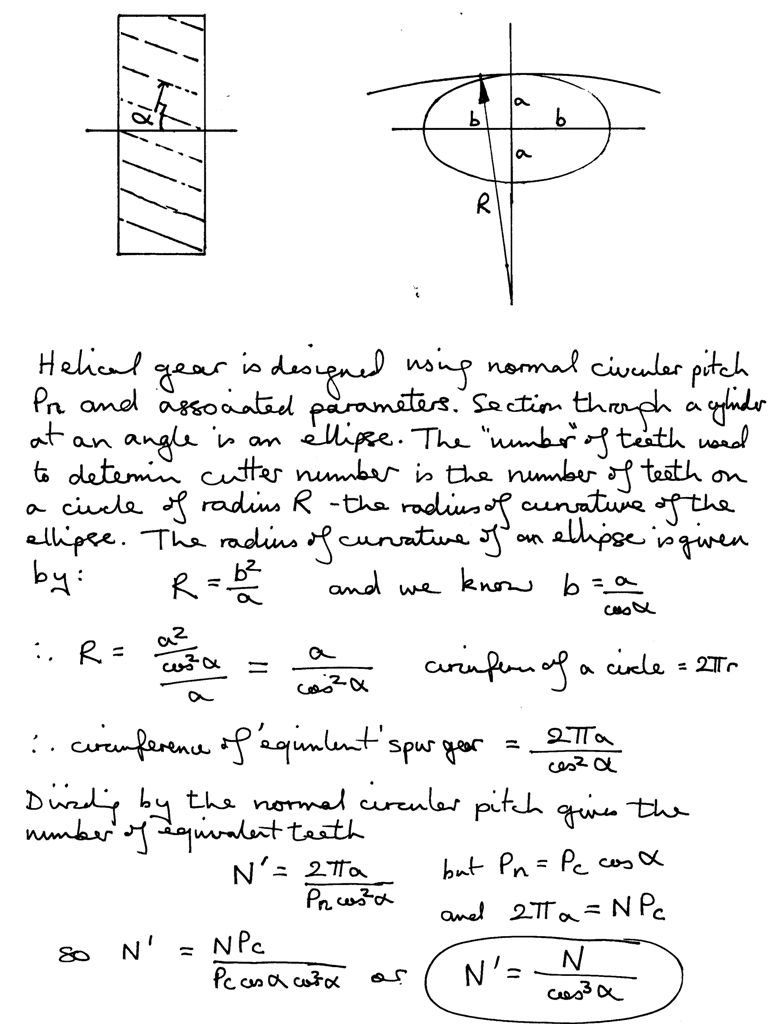

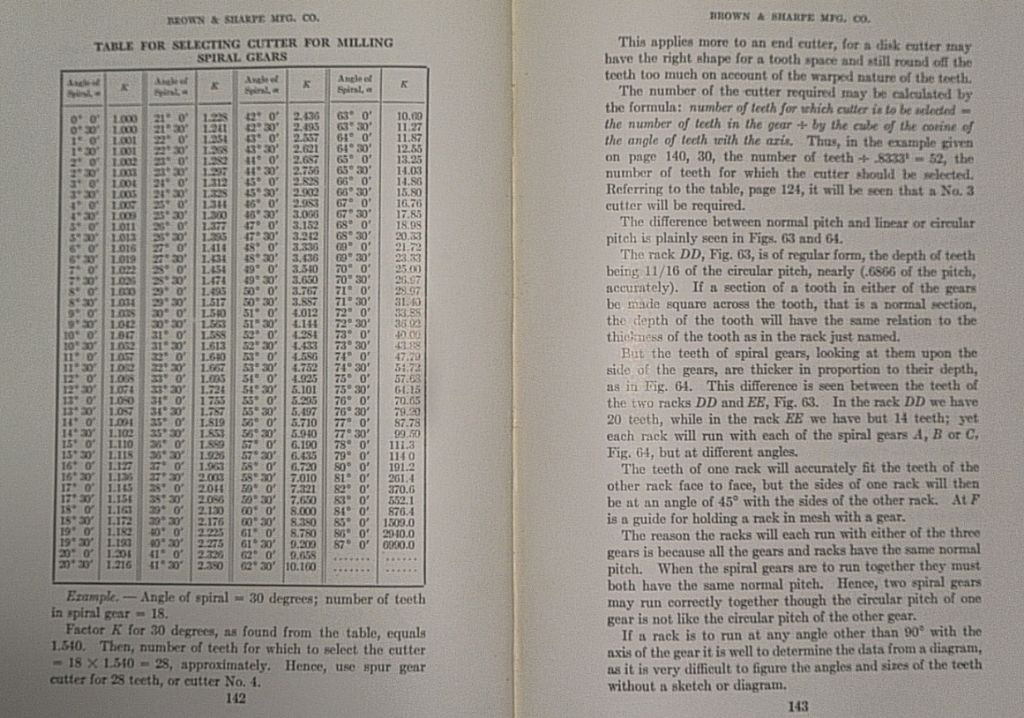

I assume that anyone reading this thread has some interest in the subject matter, or is hopelessly lost, so I'll continue where the other threads left off by showing that the equivalent number of teeth used to select the appropriate involute cutter is given by the actual number of teeth divided by the cube of the cosine of the helix angle:

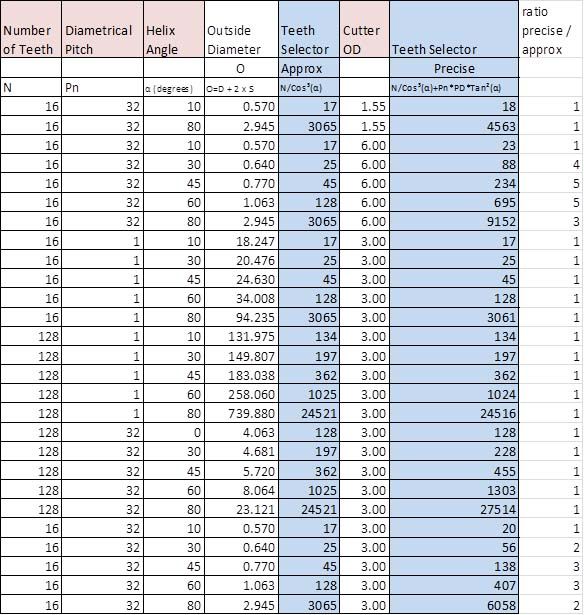

So far so neat, but at this point it all goes pear-shaped. There are inconsistencies in the literature as to when the above equation is valid, and what equations might replace it.

I found one online book stating that N' is given by N divided by the square of the cosine, multiplied by the sine, both of the helix angle. The example given was for a helix angle of 45º, which of course works since cos(45º ) = sin(45º ). However, if we examine what happens at a helix angle of 0º, ie, a spur gear where N' = N, the equation blows up as sin(0º ) = 0. And division by zero is undefined. So I'm going to ignore that version of the equation.

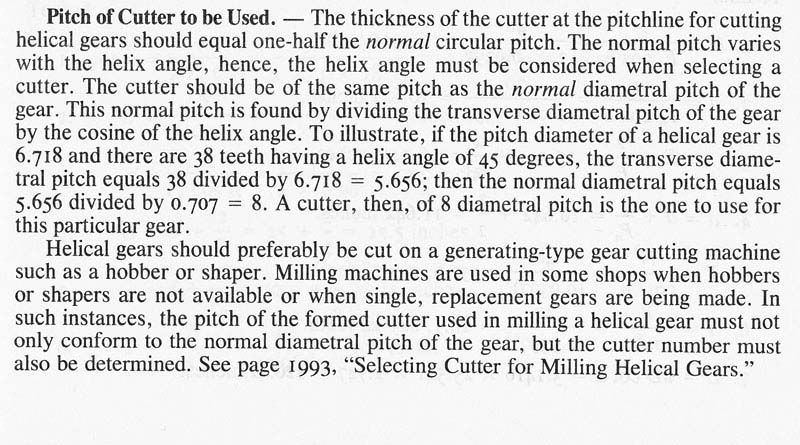

I have found two other variants. One, from Machinery's Handbook, adds a second term involving the tangent of the helix angle and the pitch diameter of the cutter. Another online source gives an equation that involves both the tangent of the helix angle and the helix angle itself.

More notes on this will follow when I've had another look at the equations and made some sense of them. However my current thinking is that the corrections are needed because the involute tooth form, normal to the helix angle, which we assume lies in a plane does not in fact do so as a consequence of the helical path of the teeth.

Andrew

Edited By JasonB on 25/07/2015 20:39:56

Anonymous.