Another M type fan / victim here.

Much depends on how much you have invested in the ole girl currently, how much tooling you have, and how much you are willing to punt in the future. You've seen the prices asked for M type bits and bobs; crazy IMO.

What you have right now is an old machine, quite worn and lacking some parts. If you look on it as a fun project in itself, and don't actually need a fully competent lathe straight away, then fine, but if you want to use a lathe to make things without a good deal of time and money invested in fettling, this probably isn't the place to start.

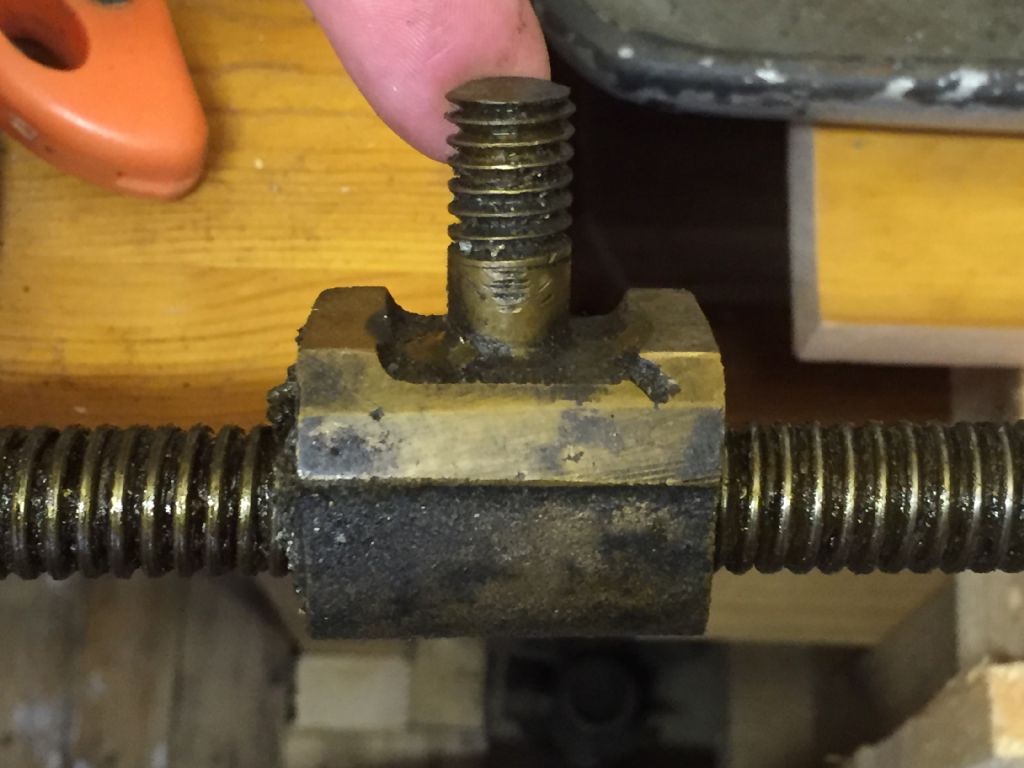

As to specifics …. the lead screw looks to be standard; can't comment on the shoulder because I've never disassembled one, but Im guessing it must be pinned or just possibly, sweated. The change wheel "bolts" are actually thread-less spring pins; there is a drawing on the Drummondlathe website in the files section.

The other areas you might check before making a decision on future progress is wear and tear on the bed ways, the state of the spindle and bronze bearings, and the condition of the saddle and cross slide gibs / vees.

Sorry to sound a bit cautious, but I've been where you are, and whilst some of it was fun and instructive, a lot of it wasn't. On the positive side once you've got an M type sorted, even a novice like me can produce some surprisingly good work, which is very satisfying.

Eug

Michael Gilligan.

Michael Gilligan.